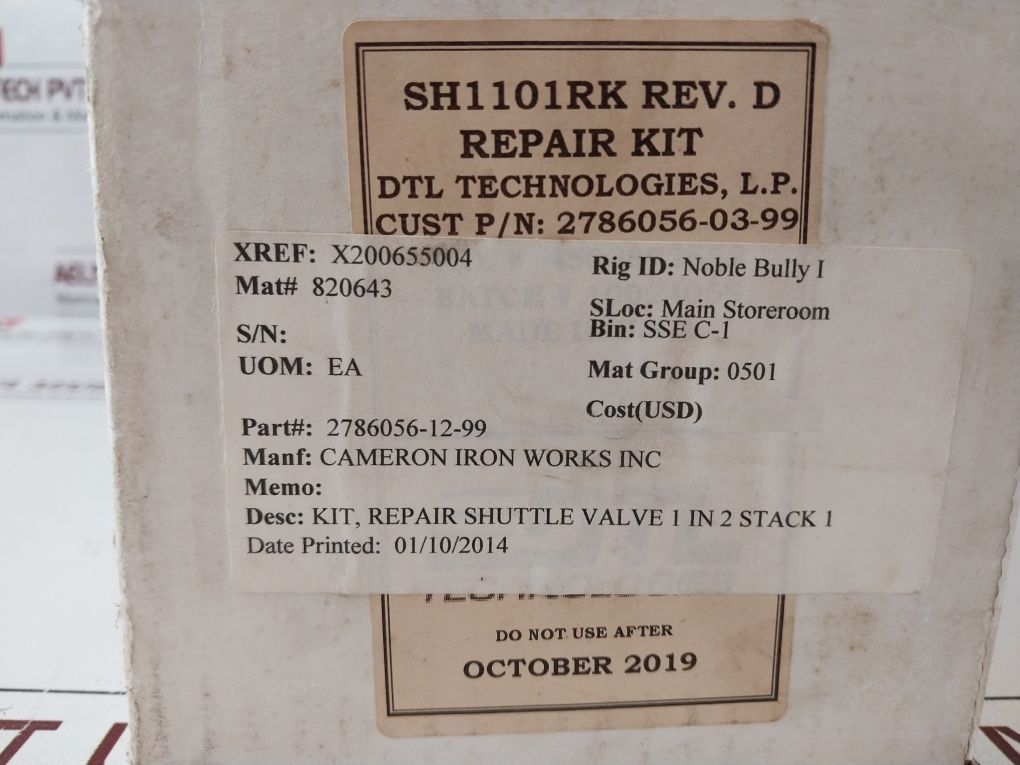

Dtl Technologies Cameron Iron Sh1101rk Shuttle Valve Repair Kit

Dtl Technologies, L.p.

Sh0020

Sh0019

Er123c

Eb123kt

Er226b

Er214t

Sh0018

Sh1101rk Rev. D

Repair Kit

Xref: X200655004

Mat#: 820643

Part#: 2786056-12-99

Manf: Cameron Iron Works Inc

Desc: Kit, Repair Shuttle Valve 1 In 2 Stack 1

Made In U.s.a.

Weight : 1.840 Kg

Condition : New 3 Kit

Ref No : 64508

Why the SH1101RK Shuttle Valve is Important

Pressure Control: The primary use of shuttle valves is the regulation of applicable pressures within a system. This is crucial to oil and gas activities, where pressure changes may result in the catastrophic failure of the system if not controlled.

Its high degree of use has been in extreme temperatures and corrosion settings to very high-pressure applications, and like any mechanical part, these tend to wear out.

Efficiency: These valves control the fluid flow between various points, enabling a system that ensures efficiency without much downtime for efficiency on the productive side of things.

Role of the DTL Technologies Repair Kit

The Cameron Iron SH1101RK Shuttle Valve is a very well-designed tool that can last a long time. However, it is constantly stressed; if it is put to use under stress conditions, like in an oil rig, then there will be constant pressures on the equipment and tools used. Therefore, eventually, the seals and gaskets that lie within the valve may break, allowing leaks to appear and increase inefficiency or even cause a system failure if extreme.

That is exactly where the DTL Technologies Cameron Iron SH1101RK Shuttle Valve Repair Kit comes into play.

What’s Included in the Kit?

The kit is tailored to solve the most commonly associated issues with shuttle valves. While the specific components might vary depending on the specific needs of the valve, a standard SH1101RK shuttle valve repair kit might include:

Replacement seals and gaskets: They do ensure that there is no leakage, and the valve will not lose its pressure control feature.

O-Rings: One of the most important parts; they ensure the seal is always tight on the different parts of the valve.

Internal Springs: Over time, some springs in the valve will lose tension, and thus, the efficiency of the valve is reduced. The kit contains top-grade substitutes to make sure the valve is flawless.

Valve Seats and Discs: The parts are most prone to wear and tear, especially in the high pressure variety. Maintenance with replacement extends the valve life.

Advantages of Using DTL Technologies Repair Kit

Cost Efficiency: Maintenance using the SH1101RK repair kit may avoid expensive times and equipment failures since instead of an entire valve being replaced, it is only targeted replacements provided by the kit that is done, saving time and money.

Valve Performance: After the replacements, the valve will be in its best functional condition to work as it was before, ensuring efficient pressure control and fluid management.

Long Equipment Life: There is no way of keeping a piece of equipment working for an extended period except for maintenance. Using DTL Technologies’s repair kit ensures your shuttle valve will continue performing great for years even in the toughest conditions.

Reliability in Harsh Environments: The products which are a part of your repair kit are made with the knowledge of the harshest conditions experienced with most oil and gas fields. In this way, you can be ensured that your equipment will stay functional even as conditions turn sour.

How to Use the Repair Kit

Using your DTL Technologies repair kit is easy if you keep mindful of how to maintain your shuttle valve. Here’s a summarized step-by-step guide:

Power down the system: Prior to initiating the repair, make sure the system is totally de-pressurized.

Disassemble the valve: Carefully disassemble the shuttle valve and keep a record of where each component is located.

Inspect for Wear: Inspect the shuttle valve for wear or damage prior to replacing any components. Be sure to inspect the seals, gaskets, and O-ring in particular.

Replace Parts: Use parts from the repair kit to replace all worn or damaged parts while being careful to properly align them.

Replace Valve: After replacing all the parts, reassembled the valve and examined it for leaks as well as other problems.

Run System: Allow the system to run under control after the replacement while testing if everything is in proper order.