| Attribute | Value |

|---|---|

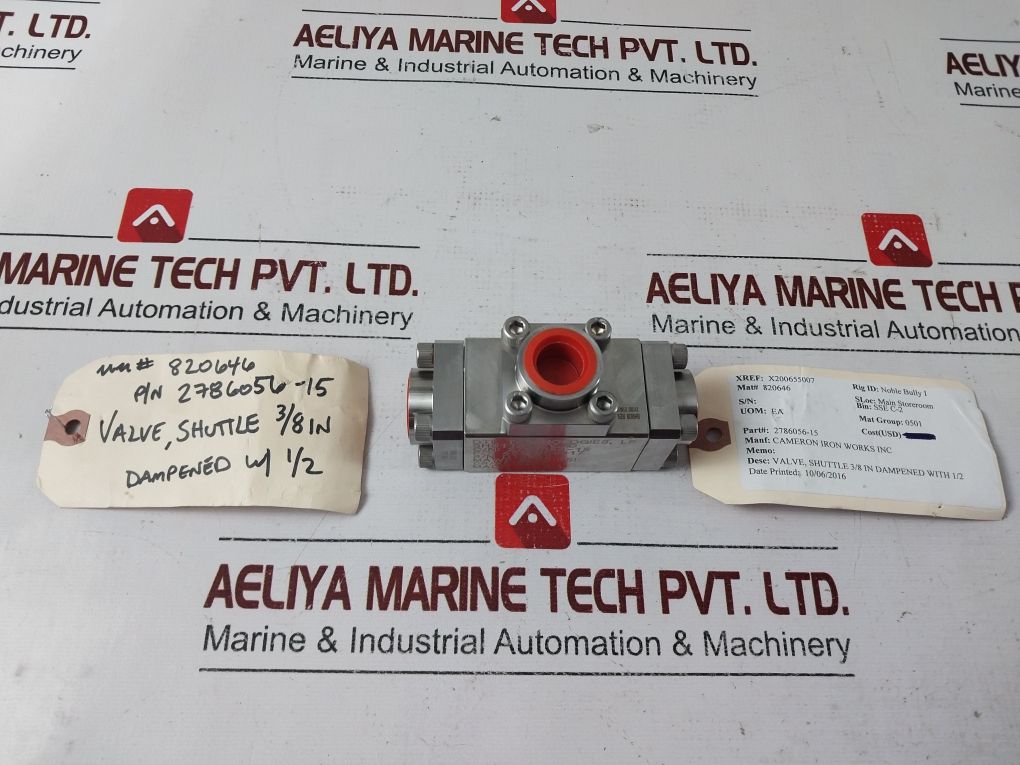

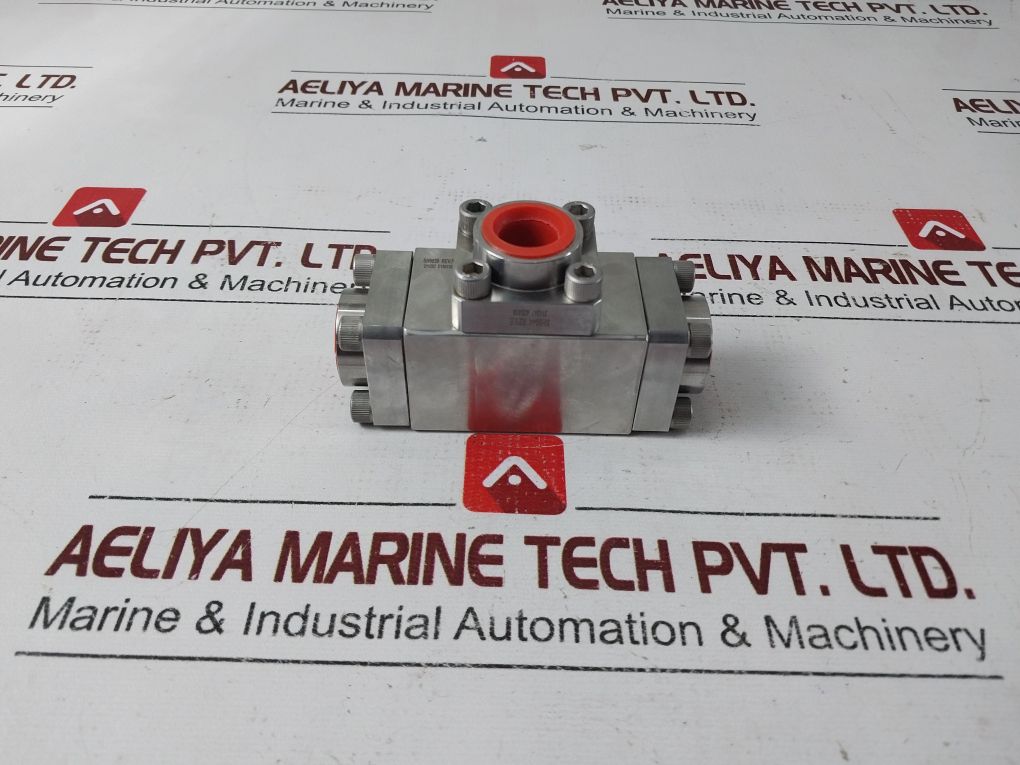

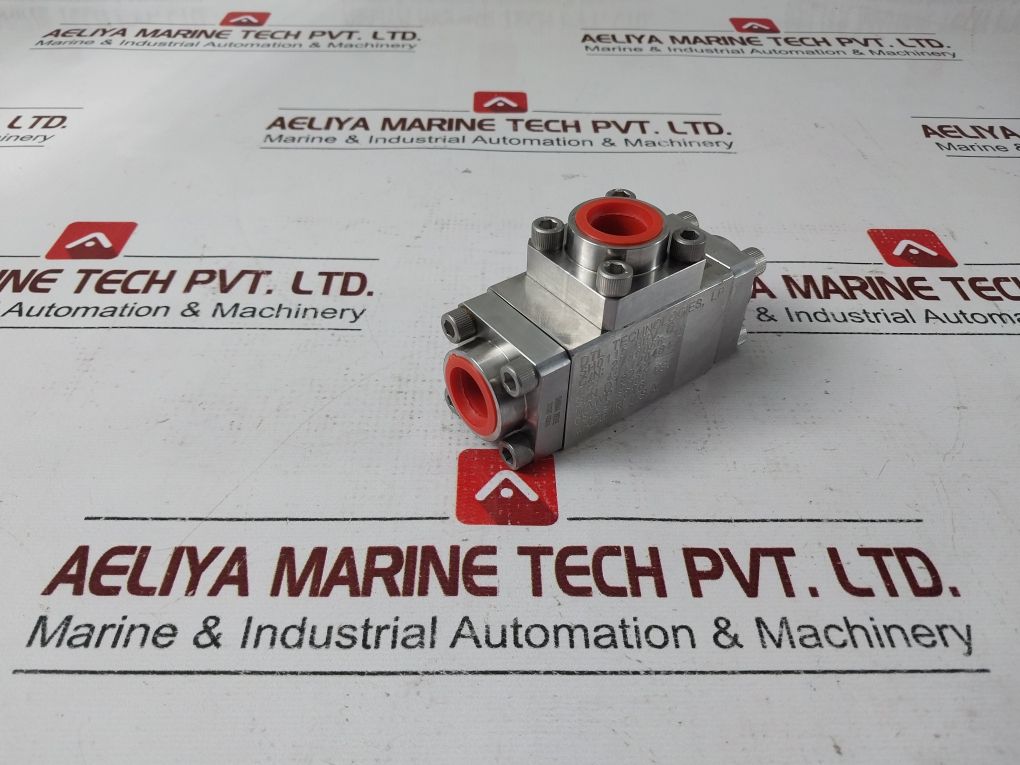

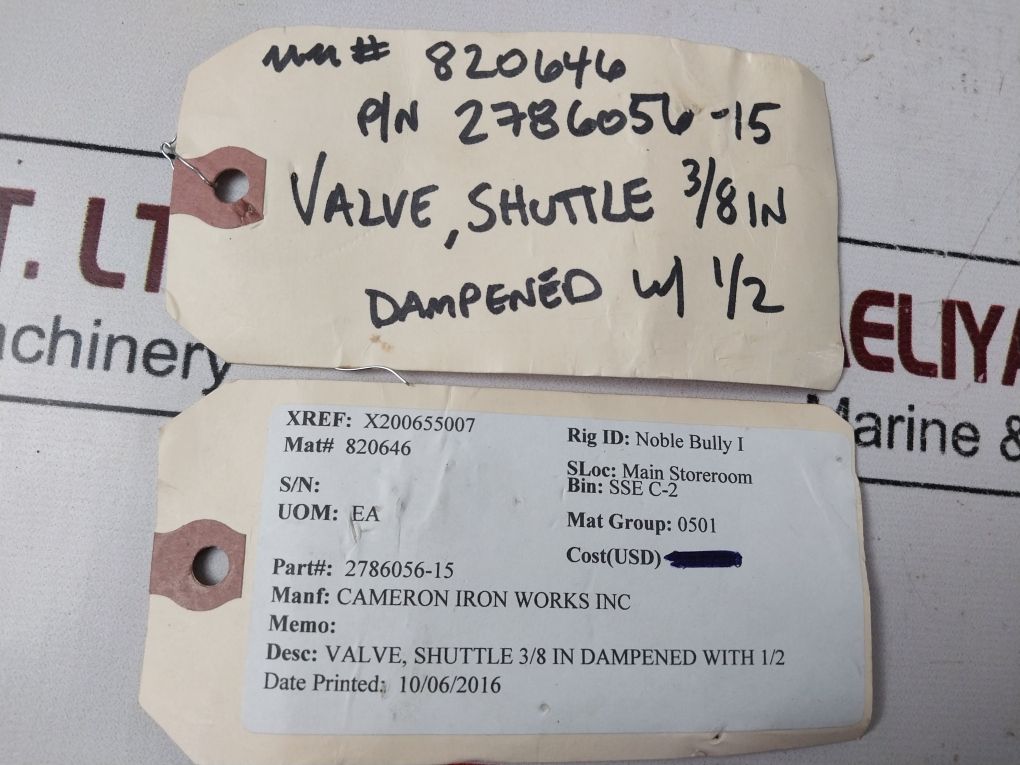

| Product Name | Dtl Technologies Cameron Iron Sh0115 Shuttle Valve |

| Manufacturer | Dtl Technologies, LP / Cameron Iron Works Inc |

| Model/Revision | SH0115 Rev. D / SH0044 Rev. E |

| C/N Part Number | 2786056-15 |

| MAWP | 5000 PSI |

| Other Codes | 211247 / 425419 |

| Description | Valve, Shuttle 3/8 In Dampened With 1/2 |

| Xref | X200655007 |

| Material Number | 820646 |

| Country of Origin | Made in U.S.A. |

| Weight | 1.040 Kg |

| Condition | New 1 Pcs |

| Reference Number | 64103 |

What is a Shuttle Valve?

A shuttle valve, also referred to as a “double check valve,” is a flow controller that permits fluid to travel between two alternate sources to one outlet. It is intended to allow pressure from one side not to leak into the other and vice versa—hence its best use in hydraulic and pneumatic systems where redundant or emergency backup dual pressure sources are needed.

Introduction of the Cameron Iron SH0115 Shuttle Valve

The SH0115 valve by DTL Technologies, which is modeled after the well-known Cameron Iron Works design, is designed for heavy-duty applications. Regardless of whether utilized in subsea blowout preventers (BOPs), hydraulic control panels, or drilling rigs, this valve is relied upon for both precision control and its durability.

Key Features and Benefits

1. Rugged Construction

Made of high-quality iron alloy and corrosion-resistant treatment, the SH0115 is designed to endure offshore and severe land-based conditions.

2. Compatibility with High Pressure

Designed to support high-pressure systems without sacrificing safety or performance. Ideal for applications involving pressures of a few thousand PSI.

3. Fail-Safe Reliability

Shuttle valves are a key component in safety systems. The SH0115 provides reliable switching between primary and secondary pressure sources without leakage or delay.

4. Space-Saving and Simple to Maintain

Its small size makes it suitable for integration into confined spaces. With minimal moving parts, it’s also simple to service or replace, reducing downtime.

5. Proven to Global Standards

DTL guarantees every valve meets or surpasses international safety and performance standards, with rigorous quality control inspection prior to shipping.

Applications

Oil & Gas Offshore Drilling: Facilitates quick switching between control systems or backup pressure sources during critical situations.

Hydraulic BOP Systems: Provides seamless hydraulic pressure to emergency shut-down systems.

Marine Automation Panels: Maintains critical controls operational by controlling pressure redundancy.

Industrial Machinery: Permits operation even when the original fluid source becomes inoperative.

Why Choose DTL Technologies?

DTL Technologies stands out for building on the legacy of Cameron Iron Works components—offering best-in-class OEM-grade solutions for industrial fluid control. Their shuttle valves blend traditional durability with contemporary precision, making them a leading solution for engineers across industries.