| Attribute | Value |

|---|---|

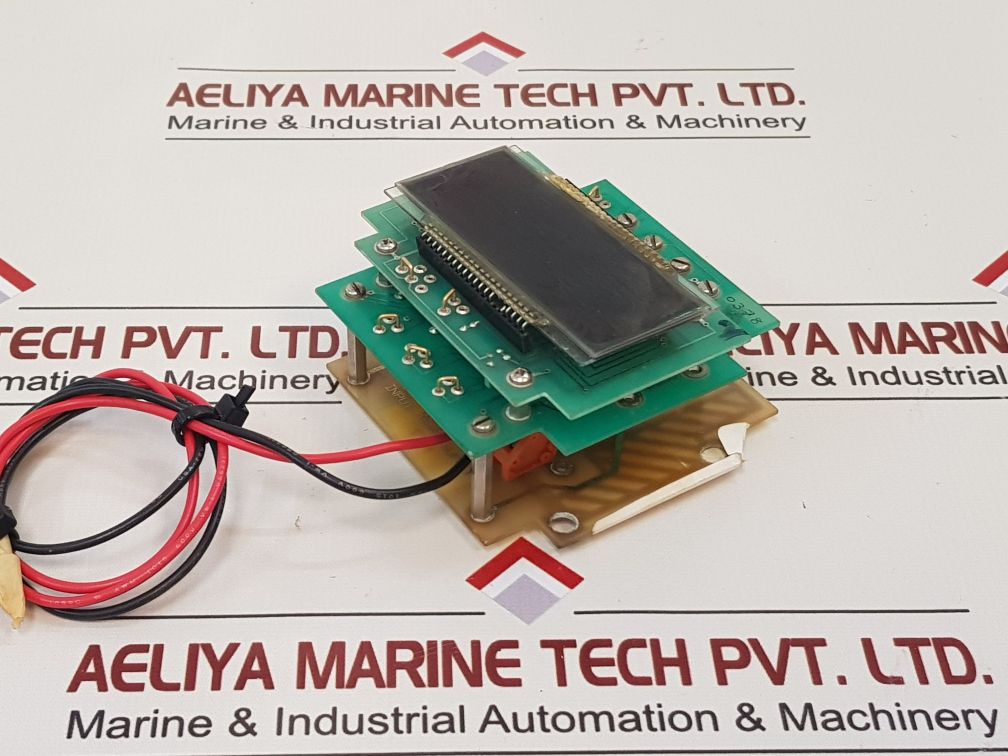

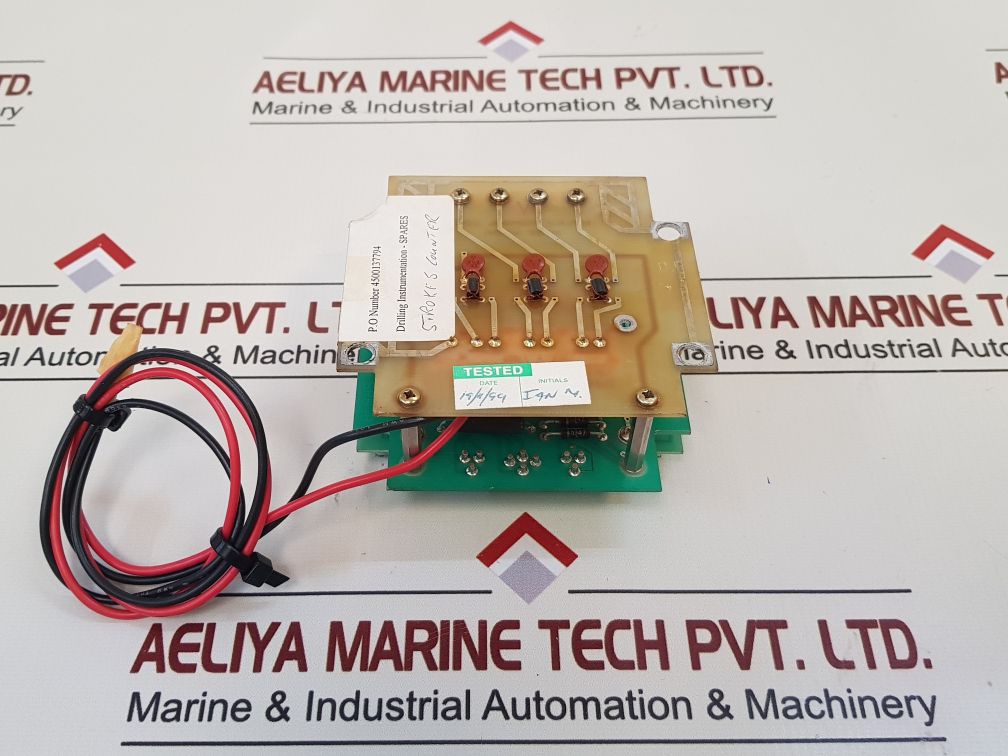

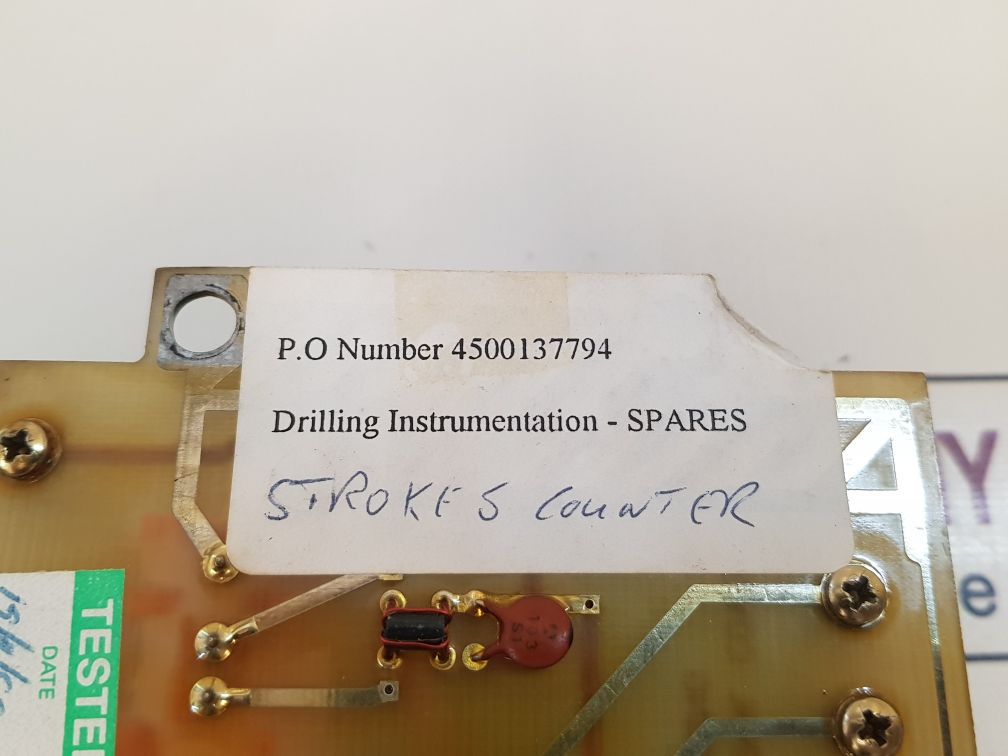

| Product Name | DRILLING INSTRUMENTATION 4500137794 |

| Part Number | 0378 |

| Category | DRILLING INSTRUMENTATION-SPARES |

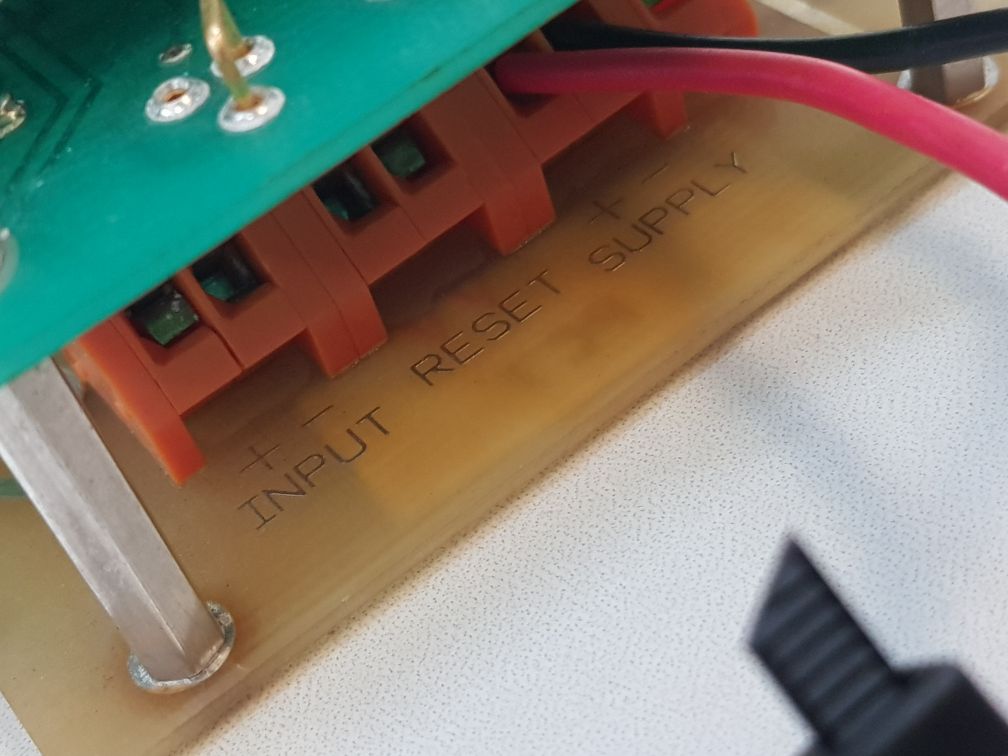

| Part Type | STROKES COUNTER |

| Weight | 200 GM |

| Condition | USED 1 PCS |

| Reference Number | 41331 |

What is Drilling Instrumentation 4500137794?

The 4500137794 Drilling Instrumentation system is intended for application in sophisticated drilling rigs, especially where accuracy, reliability, and safety are the top priorities. It tracks a number of parameters including pressure, torque, weight on bit (WOB), rate of penetration (ROP), and mud flow. With its heavy-duty construction and sensitive sensors, it makes it possible for the rig crew to make accurate decisions in real time, enhancing efficiency and safety.

Main Features

• Real-Time Monitoring: Provides instantaneous feedback of drilling parameters to prevent downtime or failures.

• Rugged Construction: Designed to withstand high temperatures, vibrations, and pressure levels of drilling conditions.

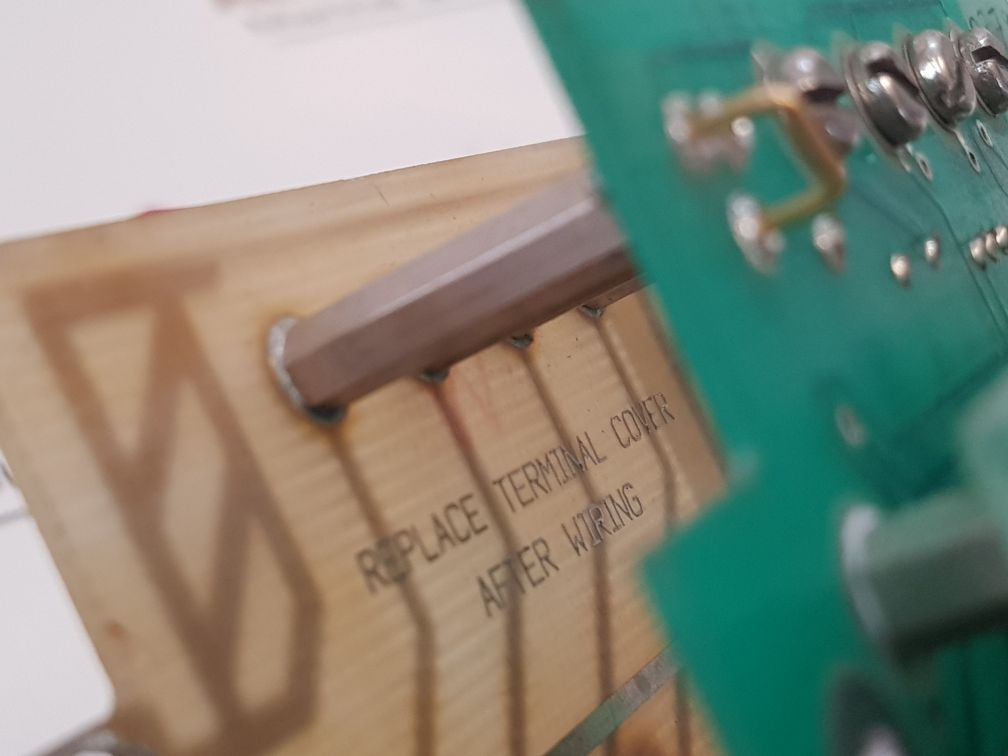

• Modular Design: Seamless integration with installed rig systems and expandable as per project requirements.

• Data Logging and Transfer: Records key data and facilitates remote transmission and analysis.

• User-Friendly Interface: Clear graphical display for on-site engineers and operators to quickly interpret data.

Uses of Drilling Instrumentation 4500137794

This equipment is used in a variety of industries, including:

- Oil and Gas Exploration

- Marine Offshore Drilling

- Geotechnical and Environmental Boring

- Directional Drilling Projects

- High-Pressure Horizontal Drilling

Why It’s Crucial?

Drilling activities are usually performed in uncertain environments. Pressure fluctuations or unexpected formations can cause accidents, tool loss, or waste of costly drilling time. It is here that instrumentation such as the 4500137794 finds application. Through continuous measurement of vital values and issuing of alarms, it aids preventive action, minimizing both risk and cost.

Further, by ensuring operational efficiency, it helps minimize wear and tear on drill parts and overall productivity. For sustainability-oriented companies, it also facilitates green drilling by preventing unnecessary excavation or energy consumption.

Benefits

• Enhanced Operational Safety

• Reduced Equipment Downtime

• Better Data-Driven Decision Making

• Greater Efficiency & ROI

• Environmental Compliance Facilitation