| Attribute | Value |

|---|---|

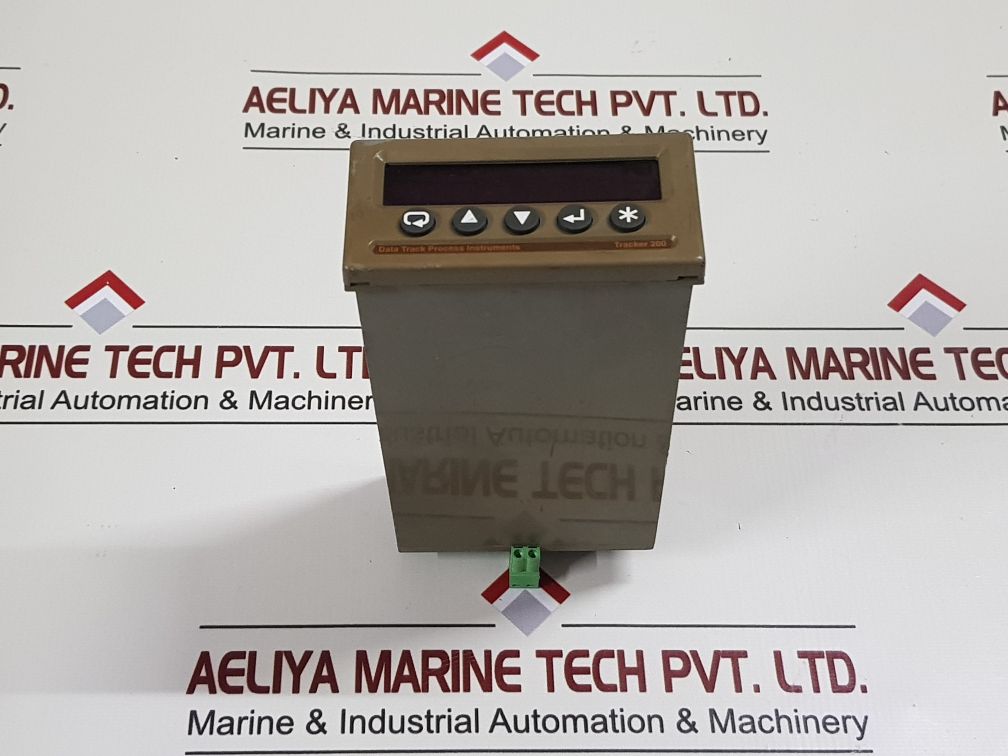

| LOAD CONTROLS SYSTEMS PTE. LTD. | TRACKER 200 |

| MODEL | 280 |

| RELAYS | RED |

| SUPPLY | 90-265V, 50/60HZ |

| POWER | 20VA MAX. |

| ISSUE | 20-6010 ISS G |

| ORIGIN | MADE IN UK |

| WEIGHT | 360 GM |

| REFERENCE NUMBER | 41224 |

What is a 280 Indicator Panel?

A 280 indicator panel is an advanced device, used for measuring and displaying vital process variables in terms of pressure, temperature, flow, or other parameters. Data Track Process Instruments manufacture it with a highly robust design, a user-friendly interface, and perfect accuracy.

Its modular architecture allows customization according to specific industry needs, giving compatibility with many sensors and control systems. This flexibility makes it the ideal solution to most applications, from chemical processing plants to food manufacturing facilities.

Key Features and Benefits

High Accuracy and Stability

The 280 Indicator Panel is engineered for precise measurements, ensuring that operators can rely on the data it provides. Its stability over time means reduced recalibration requirements, saving both time and cost.

Customizable Input Options

Whether you’re monitoring temperature, pressure, or other variables, the panel supports multiple input types, including analog and digital signals. This adaptability ensures seamless integration with existing systems.

Durable and Reliable

The 280 Indicator Panel has a rugged case and components with a long lifetime. It will withstand vibration, temperature changes, and humidity exposure while maintaining steady performance.

Ergonomic Design

The friendly interface makes configuration and access of data easy and simple. The screen is bright and clear, easily readable in any lighting condition.

Alarm and Output Functionality

With built-in alarm features and configurable output options, the panel enhances operational safety and provides actionable insights in real-time.

Applications of the 280 Indicator Panel

Due to its versatility, the Data Track Process Instruments 280 Indicator Panel is widely used across various industries:

Chemical and Petrochemical: Monitor critical processes such as pressure and temperature to ensure safe and efficient operations.

Food and Beverage: Maintain stringent quality control by monitoring process variables during production.

Water Treatment: monitor flow rates as well as plant system pressure. This helps with optimizing the plants’ efficiency

Pharmaceutical: to obtain regulatory compliance-measure and track key parameters recorded accurately

Benefits of the Data Track Process Instruments 280 Indicator Panel

A leading choice in an industry that requires accuracy and reliability, this 280 Indicator Panel is a clear winner. Its performance can be matched by few others; it’s user-friendly and especially robust and versatile. Businesses’ involvement in this advanced indicator panel provides greater operation efficiency, reduces downtime, and improves process control generally.