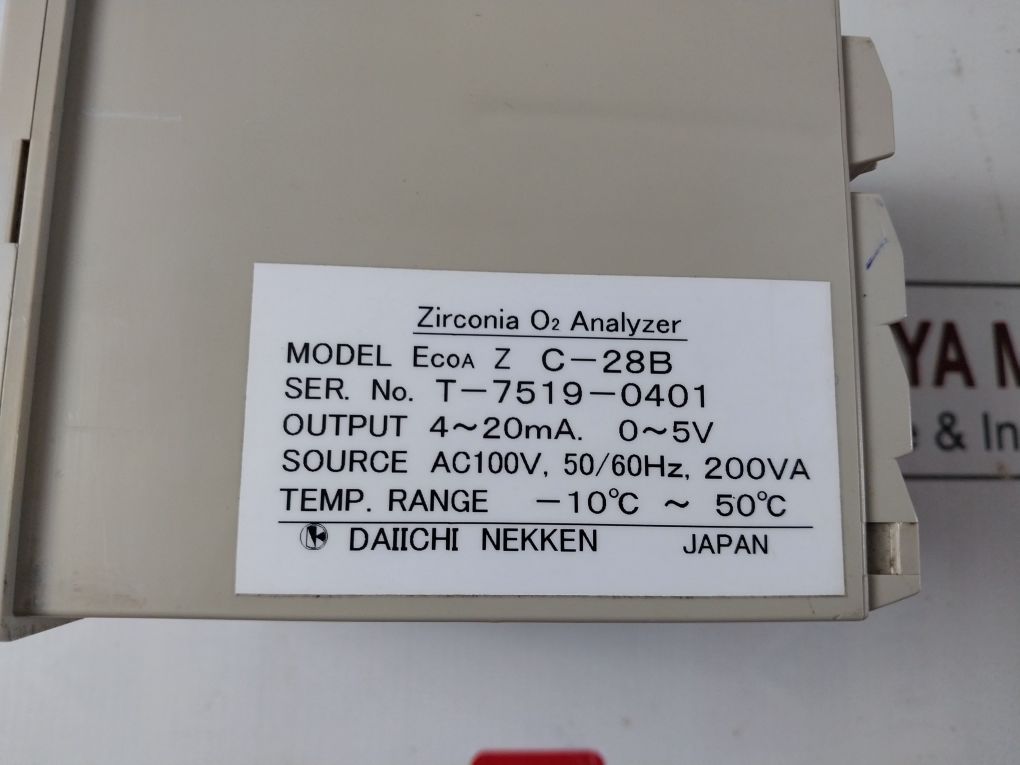

| Attribute | Value |

|---|---|

| Brand | Daiichi Nekken |

| Product Name | Zirconia O₂ Analyzer |

| Model | Ecoa Z C-28b |

| Output | 4~20mA, 0~5V |

| Power Source | AC 100V, 50/60Hz, 200VA |

| Temperature Range | -10°C ~ 50°C |

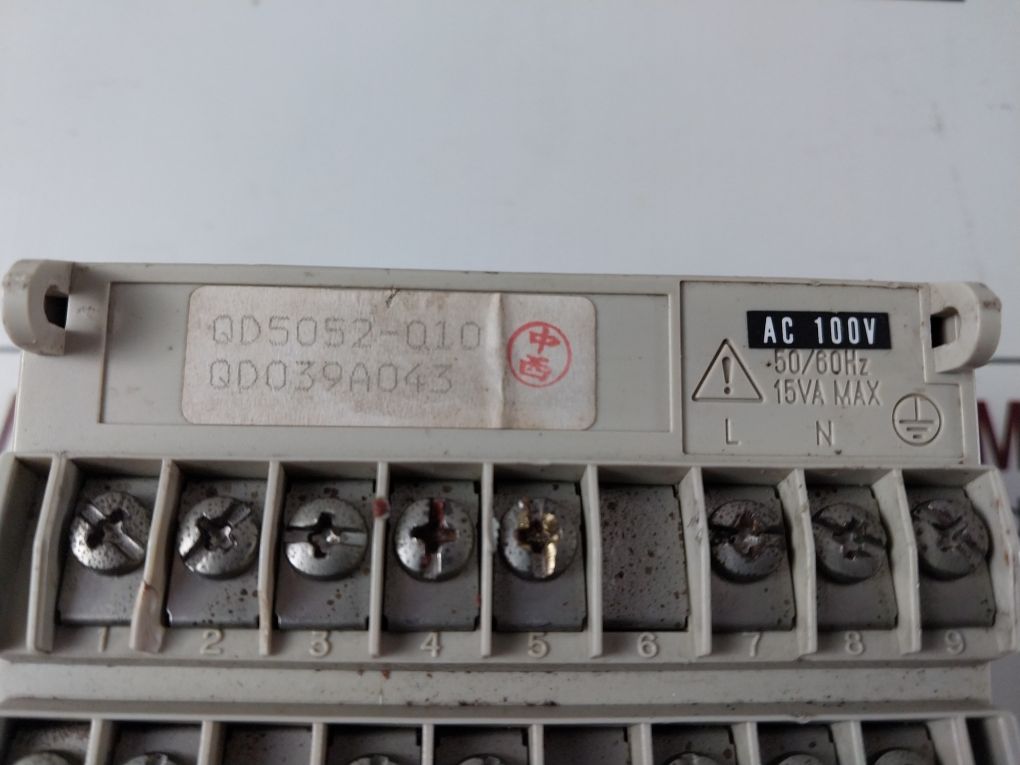

| Part Numbers | QD5052-010, QD039A043 |

| Additional Power Info | AC 100V, 50/60Hz, 15VA Max |

| Country of Origin | Japan |

| Weight | 440 gm |

| Reference Number | 64346 |

What is a Zirconia Oxygen Analyzer?

A Zirconia oxygen analyzer determines the oxygen concentration in a gas mixture through the use of a zirconium oxide sensor. The solid electrolyte responds to the difference in oxygen partial pressure over its surfaces and produces a voltage output that is related to the amount of oxygen present. The technology is commonly used because it is highly accurate, has a quick response, and is appropriate for continuous online measurement.

Overview of Daiichi Nekken’s O₂ Analyzer

Daiichi Nekken, a long-standing Japanese brand, has a variety of high-performance gas analyzers, and their Zirconia O₂ Analyzer series is especially well-known for its stability in industrial settings. The analyzer features real-time measurement of oxygen, usually from trace levels to 100%, which makes it appropriate for low as well as high-oxygen applications.

Key Features:

Zirconia Sensor Technology: Provides accurate detection of oxygen through the use of sophisticated electrochemical principles.

Fast Response Time: Suitable for dynamic process control with real-time feedback.

Wide Measurement Range: Usually 0–25% or 0–100% oxygen based on the model.

Durable Construction: Designed to handle tough industrial environments such as high temperatures and corrosive gases.

Minimal Maintenance: Designed for longevity with less calibration and maintenance requirements.

Compact and User-Friendly Design: Simple integration into different systems with easy-to-use interface and mounting configurations.

How It Works

The Daiichi Nekken Zirconia O₂ Analyzer works on the principle of the Nernst equation. When heated at a high temperature, the element of zirconium oxide transfers oxygen ions. A voltage is produced between both electrodes (reference air and sample gas) depending on the oxygen partial pressure difference. The voltage is then translated to read the oxygen concentration.

Applications Across Industries

The use of the Daiichi Nekken analyzer for its versatility benefits a wide range of industries:

Power Plants – Measurement of oxygen in flue gases to enhance combustion efficiency and minimize emissions.

Steel and Metal Processing – Proportional control of oxygen in furnaces for product quality.

Chemical and Petrochemical – Safety in processing conditions by maintaining oxygen levels to prevent explosive environments.

Environmental Monitoring – Stack emissions measurement for compliance with regulations.

Semiconductor Fabrication – Where ultra-low oxygen atmospheres are imperative to product quality.

Advantages of Using Daiichi Nekken Zirconia Analyzers

Improved Process Control: Proper oxygen measurement improves fuel-to-air ratios in combustion processes, maximizing efficiency.

Cost Savings: Optimizes equipment operation to decrease fuel usage and increase equipment life.

Safety Enhancement: Avoids enrichment or depletion conditions of oxygen that can cause safety hazards.

Compliance Confidence: Helps achieve environmental emission requirements through accurate data logging.