| Attribute | Value |

|---|---|

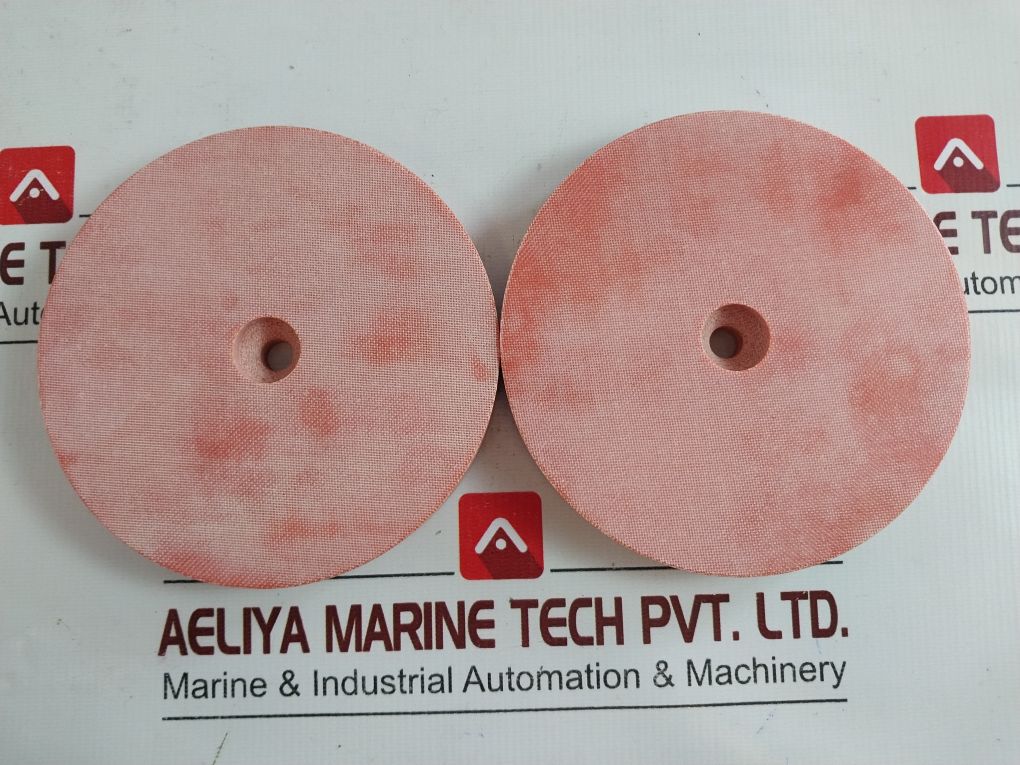

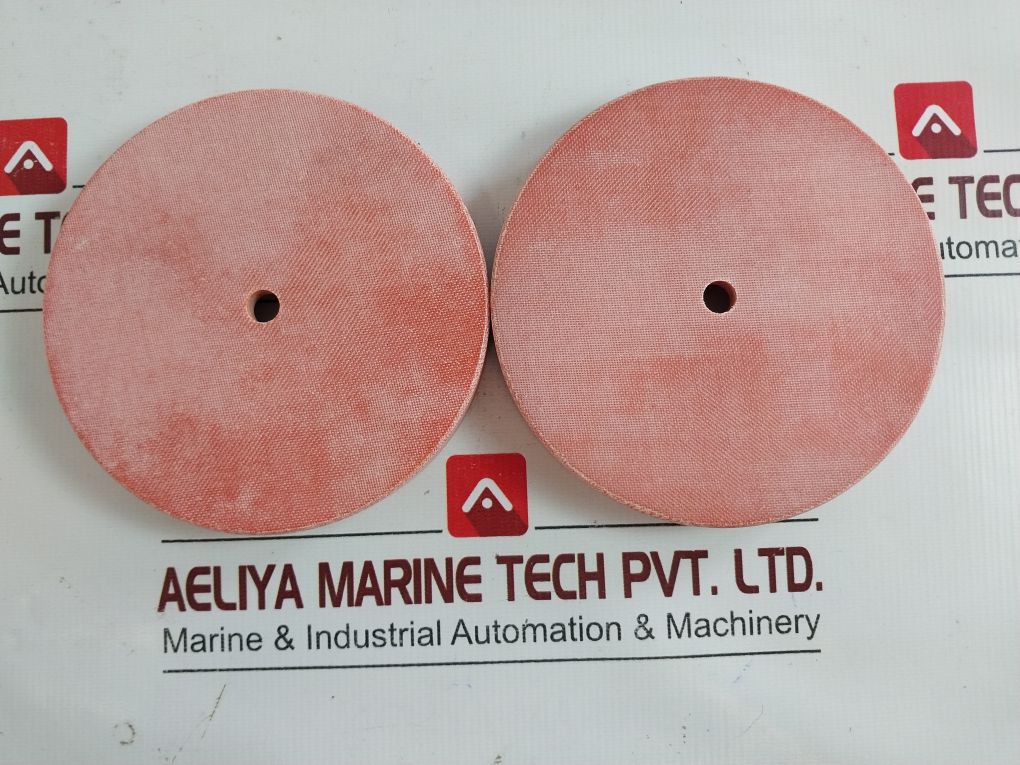

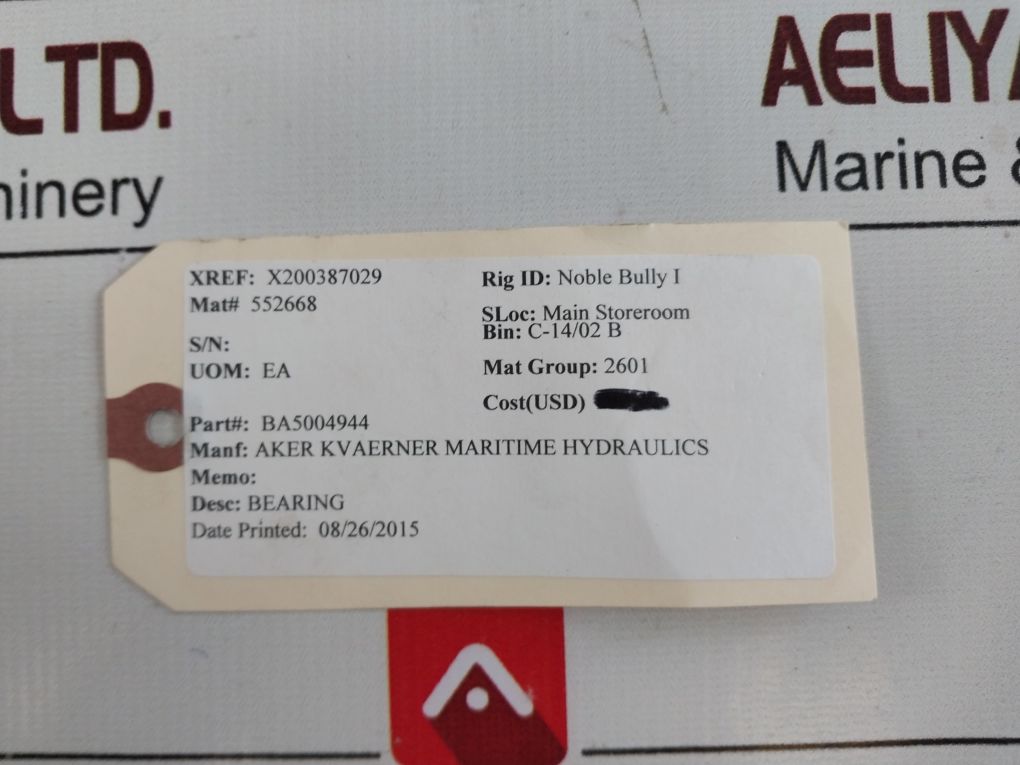

| Product Name | D-glide Aker Kvaerner Bearing |

| Brand | D-glide |

| Type | Fc |

| Part Number | Ba5004944 |

| Manufacturer | Aker Kvaerner Maritime Hydraulics |

| Material Number | 552668 |

| Xref | X200387029 |

| Description | Bearing |

| Weight | 420 Gm |

| Condition | New 4 Pcs |

| Ref No | 65157 |

What is a D-glide Bearing?

D-glide is an advanced, self-lubricating composite bearing material specifically developed for harsh environments. D-glide was made to work under extreme conditions in which conventional bearings would generally fail. Offshore engineering and project development experts Aker Kvaerner became early adopters of D-glide bearings because of their outstanding load capacity, corrosion resistance, and long cycle life.

Features and Advantages

Maintenance-Free Operation

D-glide bearings do not need lubrication, thus being best suited for use in remote or inaccessible locations where maintenance is a challenge.

Corrosion Resistance

Ideally suited for use in marine and offshore environments, these bearings withstand corrosion due to seawater, chemicals, and severe environmental conditions.

High Load Capacity

They can carry high static and dynamic loads, which is vital in lifting gear, cranes, and hydraulic structures.

Low Friction & Wear

With extremely low friction coefficients, D-glide bearings minimize wear and tear on supporting components, adding to the longevity of whole systems.

Environment Friendly

Their self-lubricating mechanism excludes greases or oils, stopping possible environmental contamination.

Variable Design Options

D-glide bearings come in varying dimensions and types, fitting well in common and highly technical uses.

Industry-Wide Uses

Marine & Offshore

Widely employed in rudder bearings, winches, mooring systems, and underwater joints that are constantly exposed to saltwater.

Hydropower Plants:

Most suitable for applications in sluice gates, turbines, and water control systems, owing to their long life and water-resistance.

Industrial Machinery:

Heavy machinery such as presses, cranes, and revolving arms are augmented by their shock absorbing and low-wear characteristics.

Civil Engineering Projects:

Employed in bearings of bridges, support joints, and other load-carrying structures that need low-maintenance and long-life solutions.

Why Use Aker Kvaerner Specified D-glide Bearings?

Aker Kvaerner has a reputation for using sound engineering practice in offshore and industrial conditions. Their use of D-glide bearings reflects their dedication to reliability and safety. The bearings are thoroughly tested and proven to withstand the most severe operating conditions over extended periods with minimal downtime and lower total cost of ownership.