| Attribute | Value |

|---|---|

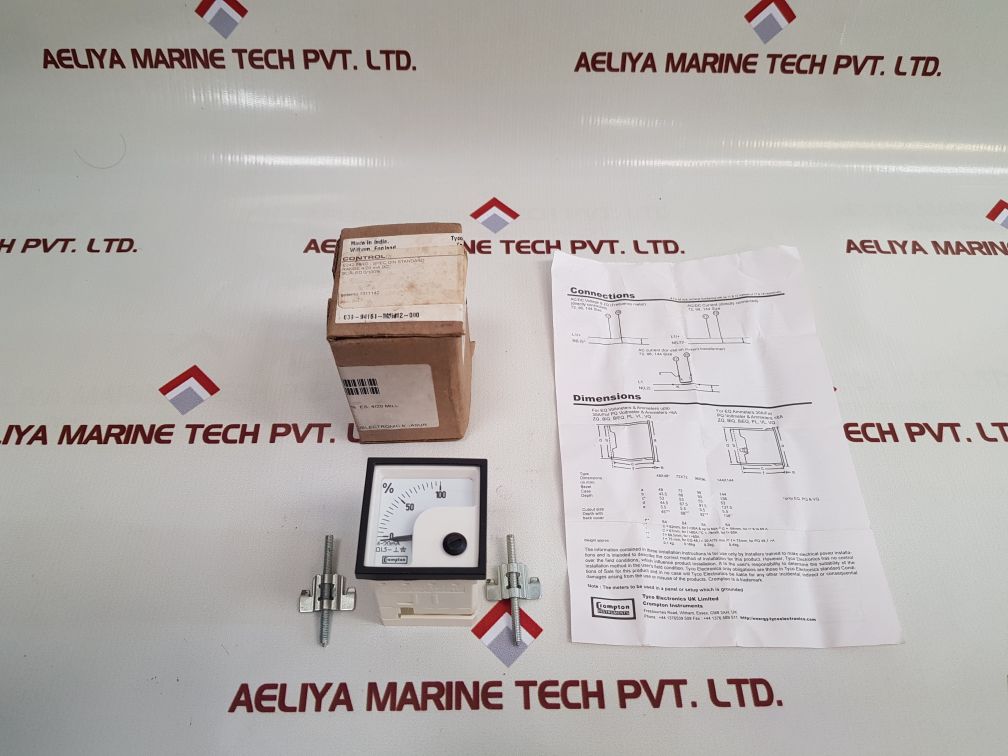

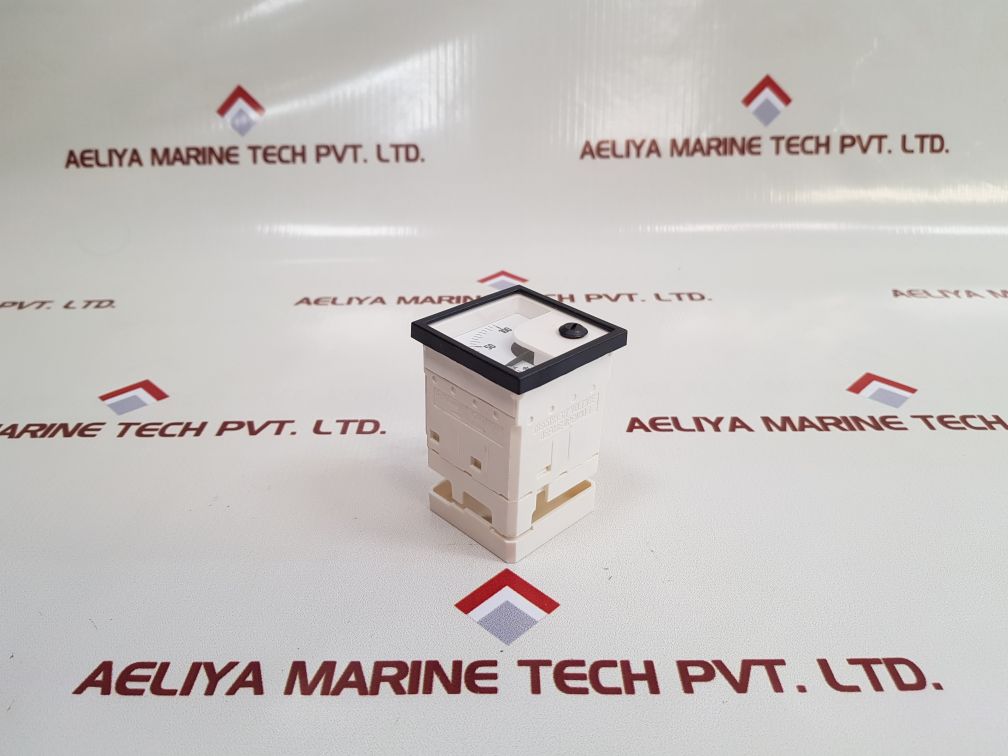

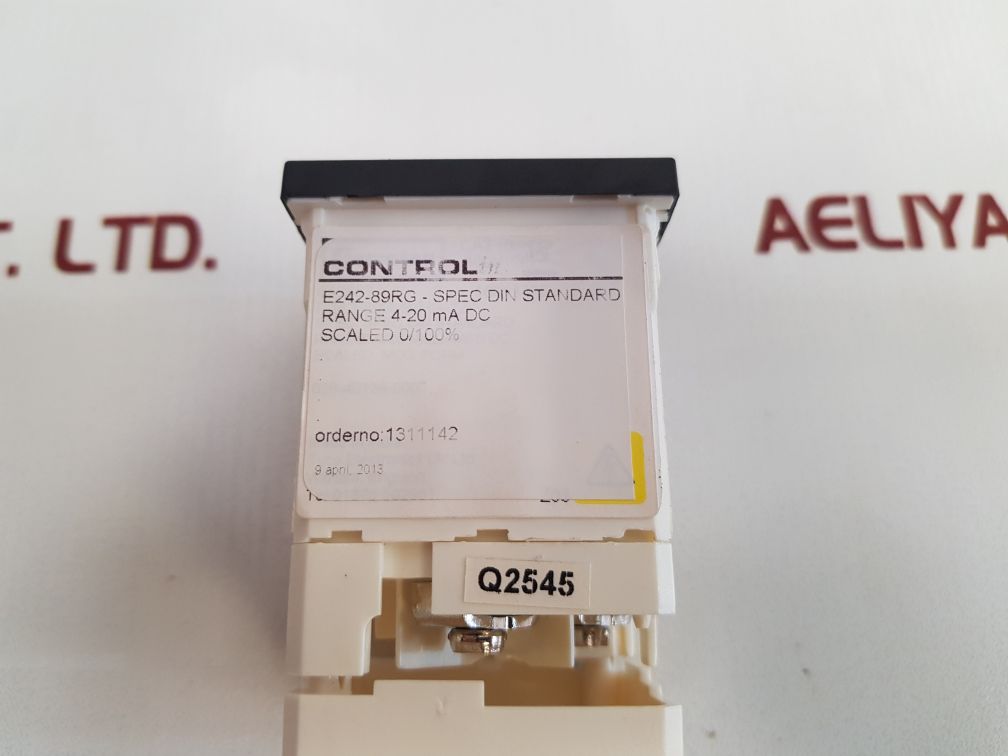

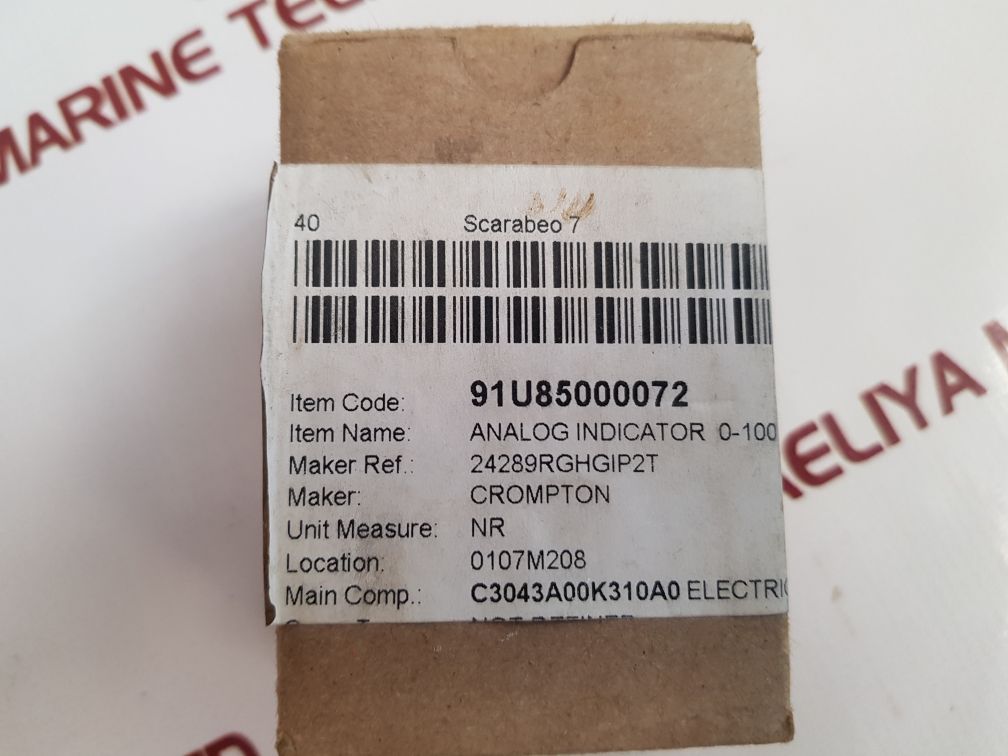

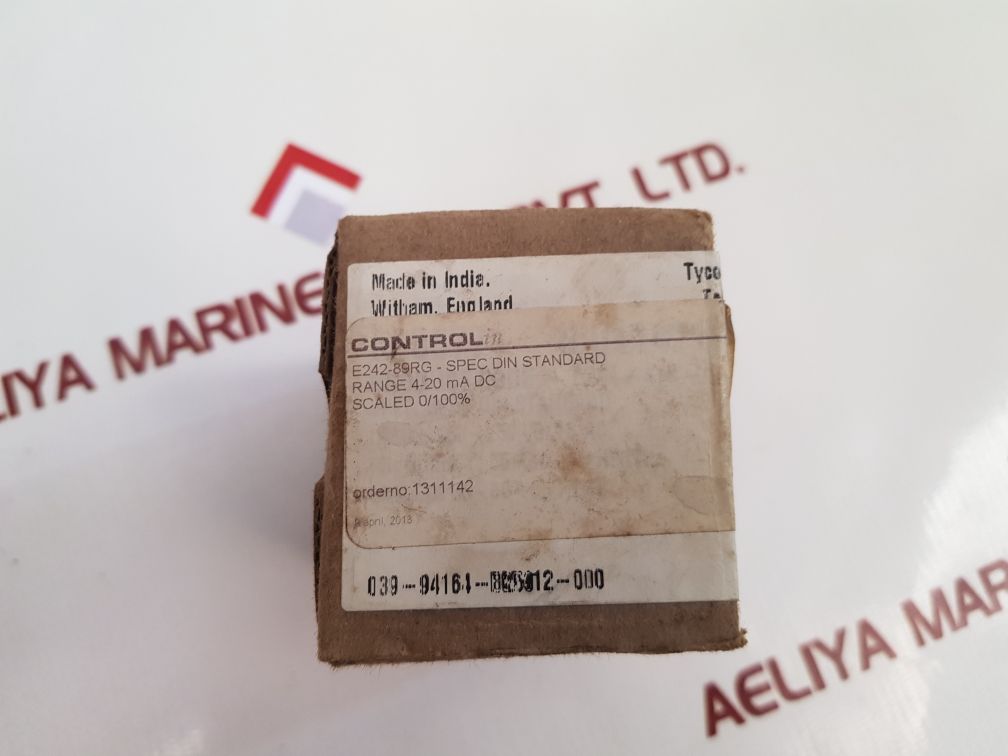

| Module | CROMPTON E242-89RG Analog Indicator |

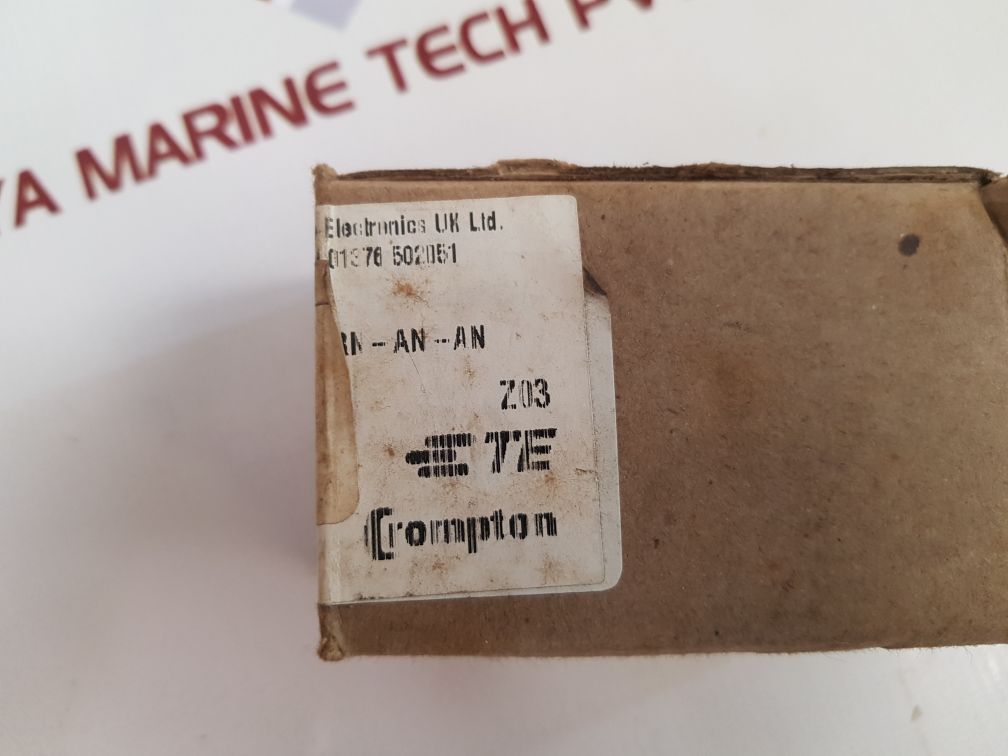

| Brand | CROMPTON INSTRUMENTS |

| Manufacturer | TYCO ELECTRONICS UK LIMITED |

| Type | CONTROL |

| Model | E242-89RG-SPEC DIN STANDARD |

| Range | 4-20 MA DC |

| Scale | 0/100% |

| Order Number | 1311142 |

| Item Code | 91U85000072 |

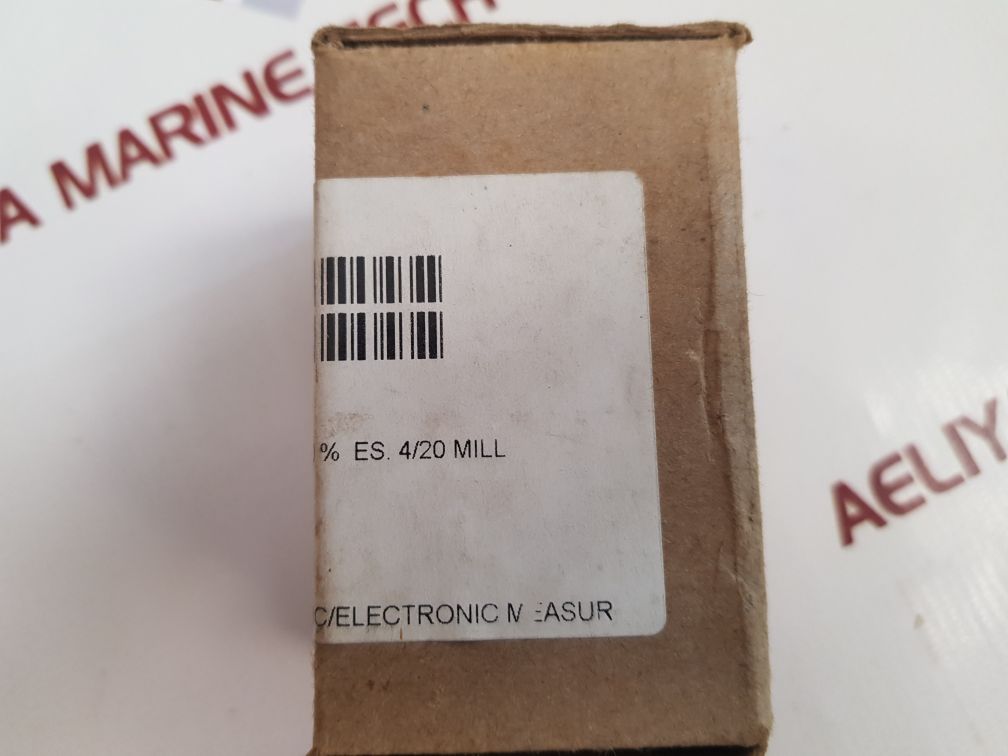

| Item Name | Analog Indicator 0-100%ES.4/20 MILL |

| Maker Reference | 24289RGHGIP2T |

| Maker | CROMPTON |

| Main Component | C3043A00K310A0 Electric/Electronic Measure |

| Country of Origin | Made in India |

| Weight | 190 GM |

| Condition | New (2 pcs) |

| Reference Number | 36079 |

Key Features of CROMPTON E242-89RG Analog Indicator

The CROMPTON E242-89RG presents very accurate measurements repeatedly. The analog mechanism is highly advanced, meaning very little margin for error.

Oversized Build Quality

This indicator is made from the best materials, guaranteeing use in hazardous conditions. It has no tendency to wear out quickly, hence life-long performance and reliability

User-Friendly Interface

The device is designed to be intuitive, making it easy to operate. The clear display and simple calibration features make it accessible even to those new to the instrument.

Versatility

Whether it’s for monitoring voltage, current, or other parameters, the CROMPTON E242-89RG adapts effortlessly to various applications, catering to diverse industrial needs.

Why Choose Analog Over Digital?

While digital indicators have gained popularity, analog indicators like the CROMPTON E242-89RG still hold significant advantages:

Robustness: Analog-based equipment is highly immune to power spurs or electrical noise.

Real-Time Measurement: Analog indications ensure visual continuous-time and current display for appropriate instantaneous action taking.

Rugged Design: Due to a simple form factor, more constituent parts decrease the possibility of technological breakdown

Applications of CROMPTON E242-89RG Analog Indicator

Due to such widespread utility and availability, applications include a cross section of:

Power Generation: To monitor power plants electrical values.

Manufacturing: Ensuring machinery operates within optimal conditions.

Automotive: Testing and diagnostics in workshops and testing facilities.

Commercial Settings: Use in retail or office environments that require monitoring equipment.