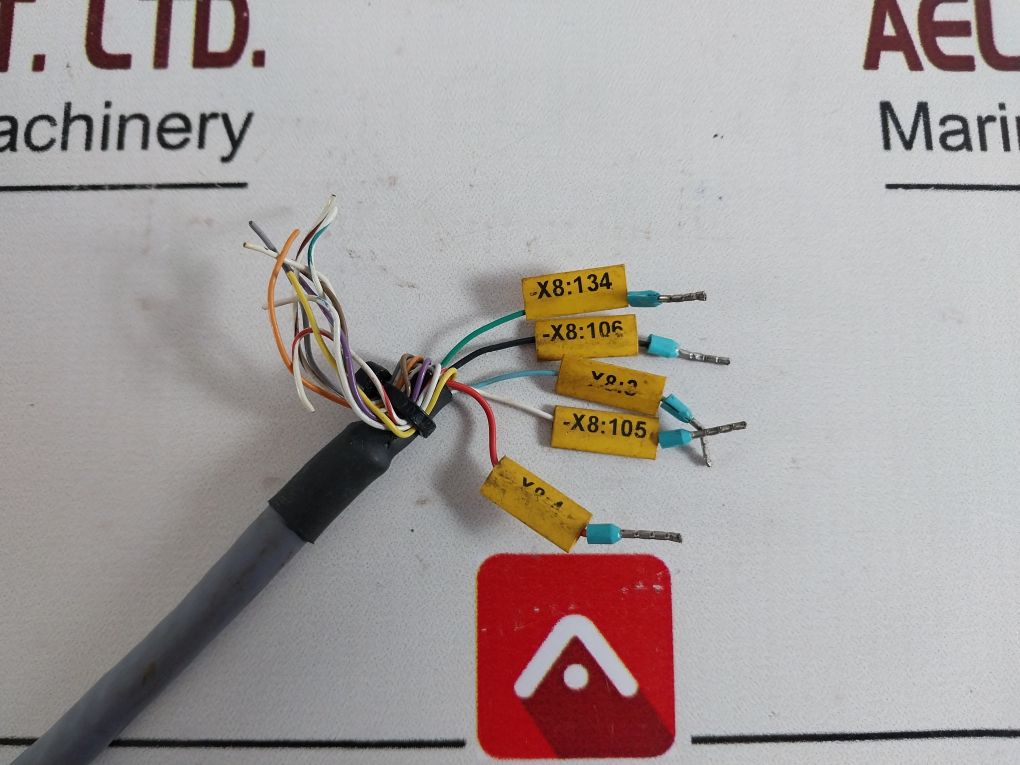

Codechamp Coa1exg1000a Encoder

Codechamp S.a.

Coa1exg1000a

1024 Points

Ue: 24v

Fab.: 11-25

No: 184

Weight : 220 Gm

Condition : Used 1 Pcs

Ref No : 61873

What is the Codechamp COA1EXG1000A Encoder?

The heavy-duty rotary encoder, Codechamp COA1EXG1000A, is designed for precise measurement of the position, speed, and direction of mechanical systems. This particular model finds widespread applications in manufacturing industries, robotics, and heavy machinery, whereby precision in motion control is realized. Be it on automated production lines or on CNC machinery, this gadget ensures that operations run smoothly with real-time data on mechanical movement.

Key Features of COA1EXG1000A Encoder

High Resolution: The COA1EXG1000A has a resolution of 1000 pulses per revolution, enabling very accurate position and/or movement even in highly complex applications.

Durable: Designed for the toughest industrial ambient operating conditions, these encoders are dust-, moisture-, and temperature-extreme resistant for good performance over a long period.

Compact Design: Compact, compact in size; this encoder is easy to install in tight spaces without sacrificing high-resolution output.

Easy Integration: COA1EXG1000A is built to work with existing control systems and interfaces with ease; thus, it is suitable in multiple configurations for both new installations and retrofits.

Why Precision Matters in Industrial Automation?

Industrial automation, where literally every second counts, minute measurement errors translate into costly shutdowns, defective products, and inefficiency. That is where the Codechamp COA1EXG1000A Encoder takes center stage, providing accurate motion information to enable automated systems to perform at full capacity and realize maximum productivity.

An encoder would provide instantaneous feedback on the position of a cutting tool. A really accurate encoder, say COA1EXG1000A, would ensure that movement of the tool is accurate and the parts coming out are finely machined to tight tolerances. In robotics, an encoder may serve to ensure that a robotic arm moves precisely as it is supposed to and doesn’t cause misalignment or damage to sensitive pieces of equipment.

Applications

Manufacturing: This encoder finds application in manufacturing assembly lines, machinery position control, regulating the speed, and monitoring of quality.

Robotics: Robotic arms and automated systems can be given highly accurate feedback to ensure high accuracy in movement and task performance.

Heavy Machinery: The heavy machinery used in mining, construction, and agriculture is equipped with this; it monitors the position and movement of machinery.

Renewable Energy: These find a place in wind turbines and solar tracking systems where they enable the monitoring of motion for better energy efficiency.

Material Handling: Allows checking conveyor belts, AGVs, and other logistics systems to ensure fluent and harmonized operation.