Chesterton 185 Joint Sealant

Chesterton

Teflon

073621-12/94

185

Joint Sealant

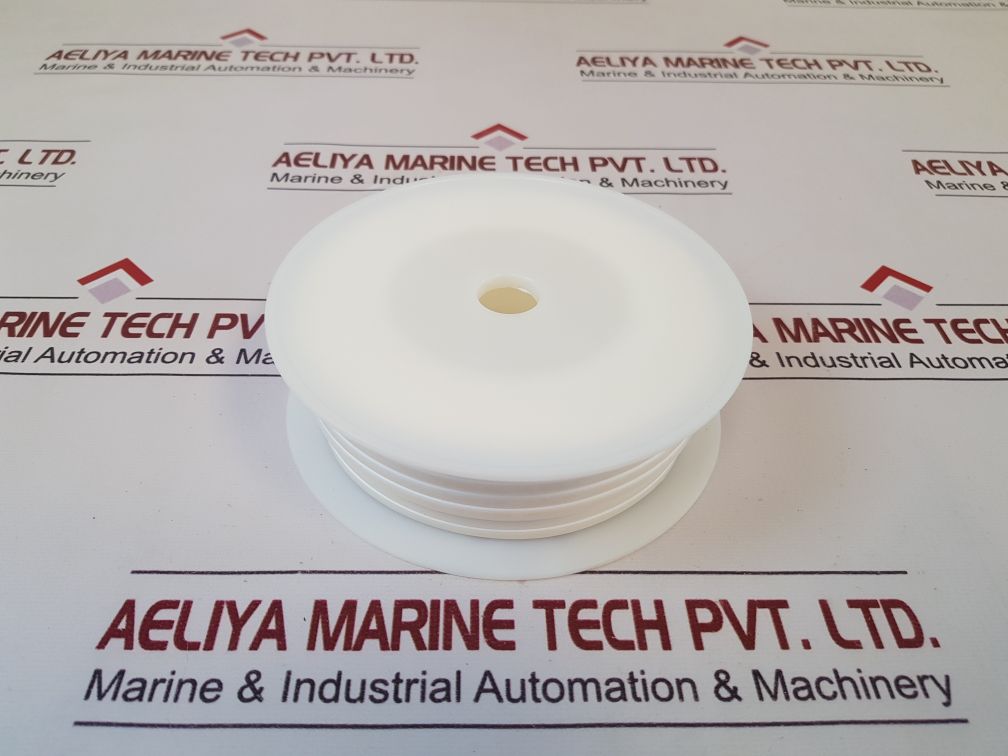

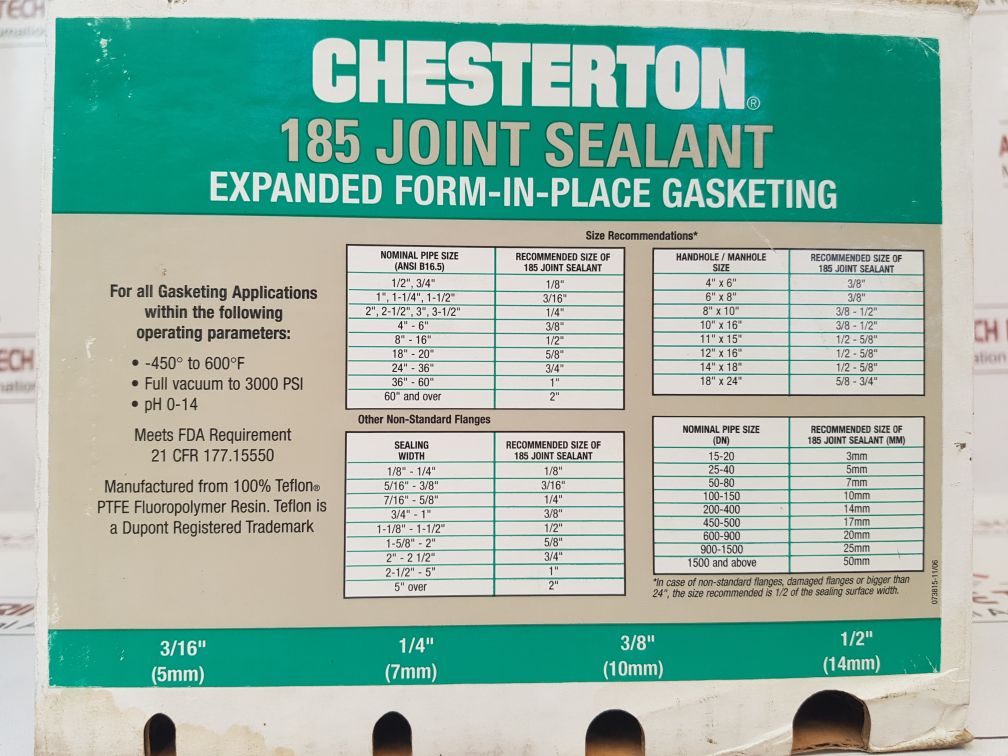

Expanded Form-in-place Gasketing

-450° To 600°f

Full Vacuum To 3000 Psi

Ph 0-14

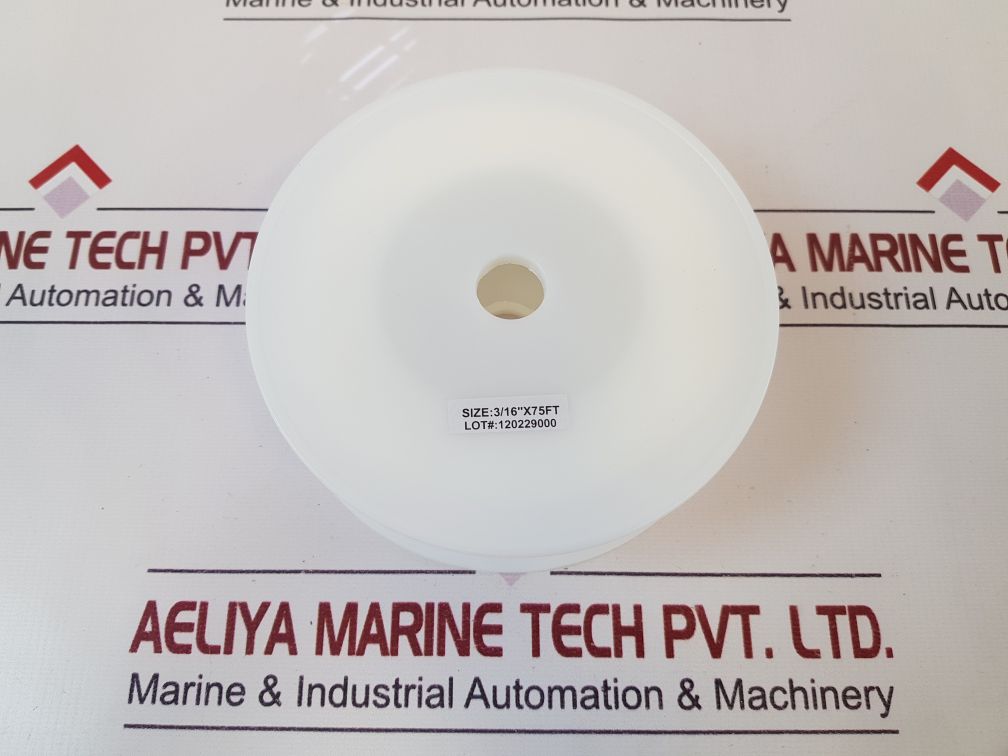

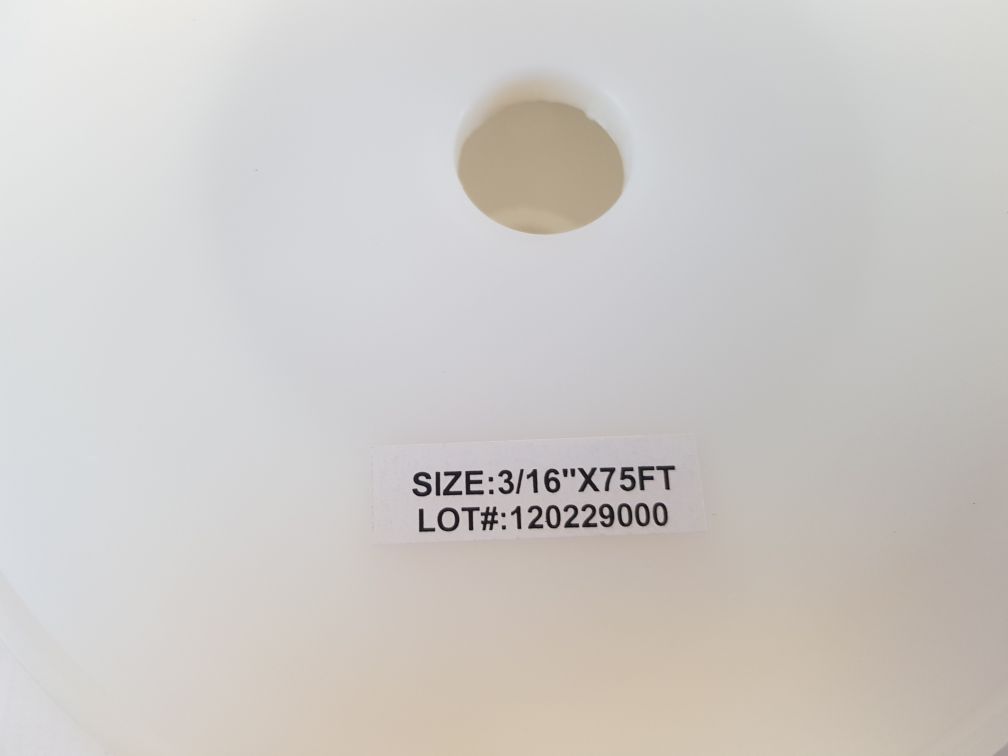

Size: 3/16”x75ft

Item# 004801

185 Ptfe Sealant Kit

Made In Taiwan

Weight : 280 Gm

Ref No : 55925

Chesterton 185 Joint Sealant

Availability: 3 in stock

| Brand | |

|---|---|

| Condition | New with original Box |

| Country of Manufacturer | TAIWAN |

| Qty Type | PCS |

| Weight | 280 grams |

- Free Shipping on Order above $100

- 30 Days Warranty

- Fast Shipping via DHL

| Brand | |

|---|---|

| Condition | New with original Box |

| Country of Manufacturer | TAIWAN |

| Qty Type | PCS |

| Weight | 280 grams |