| Attribute | Value |

|---|---|

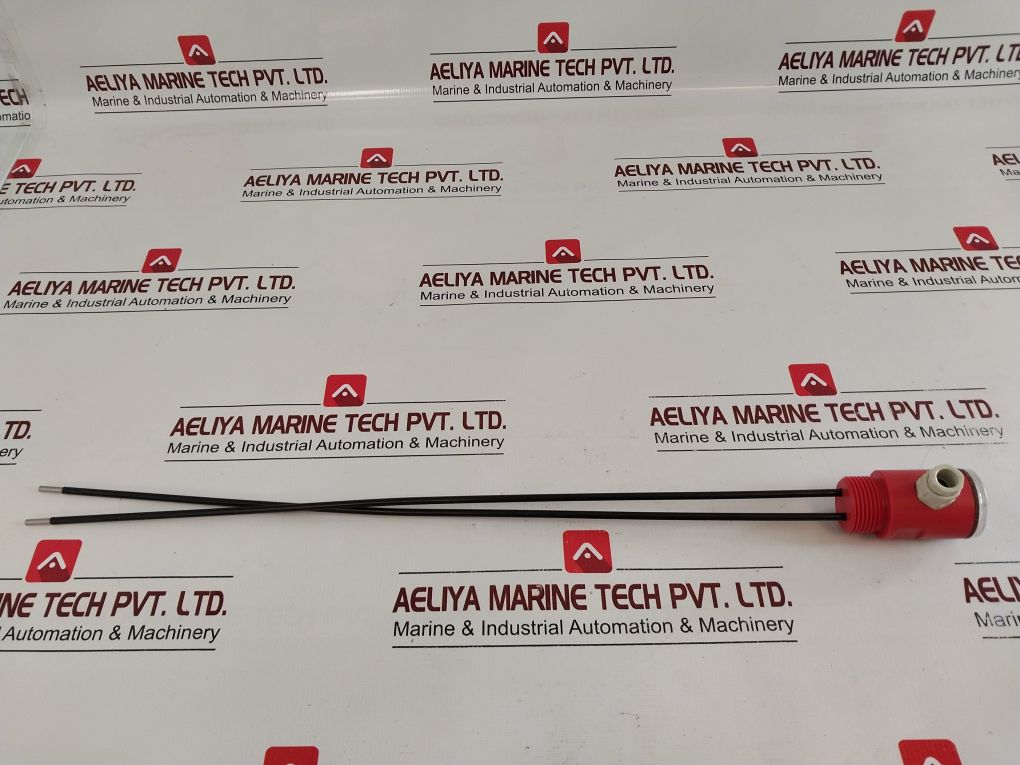

| Product Name | Carlo Gavazzi VPC210 Level Sensor |

| Brand | Carlo Gavazzi |

| Model | VPC210 |

| Product Type | Level Sensor |

| Barcode | 5 709870 048130 |

| Part Number | LL1304880 |

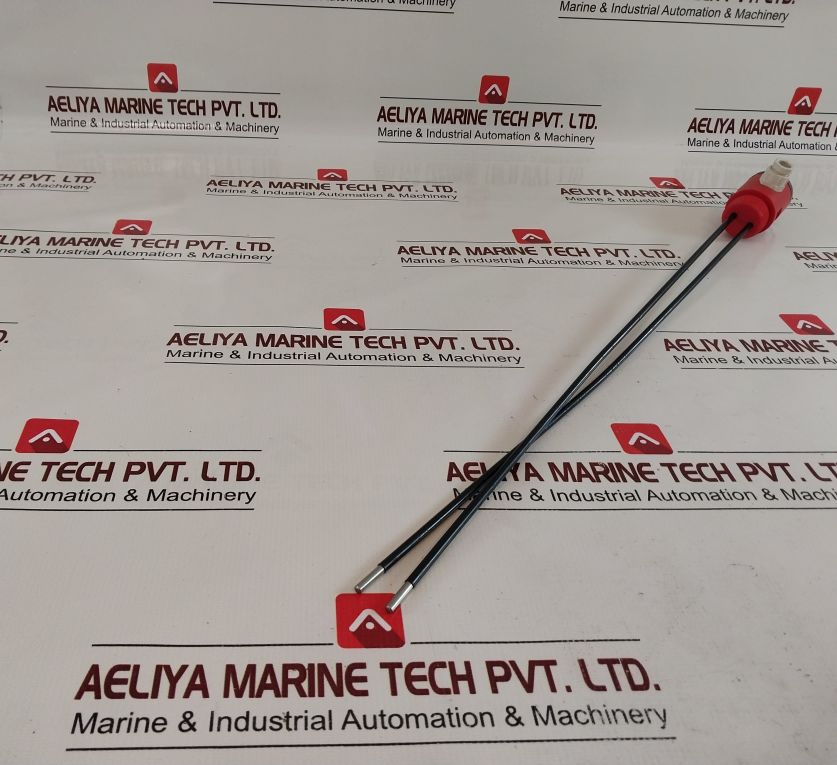

| Length | 50 cm |

| Weight | 200 gm |

| Condition | New (1 Pcs) |

| Reference Number | 62789 |

What is the Carlo Gavazzi VPC210?

The VPC210 is a capacitive level sensor by Carlo Gavazzi meant to sense the presence or absence of solids and liquids without physical contact. It presents a non-intrusive, robust, and compact solution well suited to places where the traditional float-type sensor might malfunction.

This tank sensor is also often applied to tanks, vessels, and lines for fluid-level monitoring to make sure there’s effective resource allocation and no overfill or run-out conditions.

Major Attributes of the VPC210 Sensor

1. Small Size:

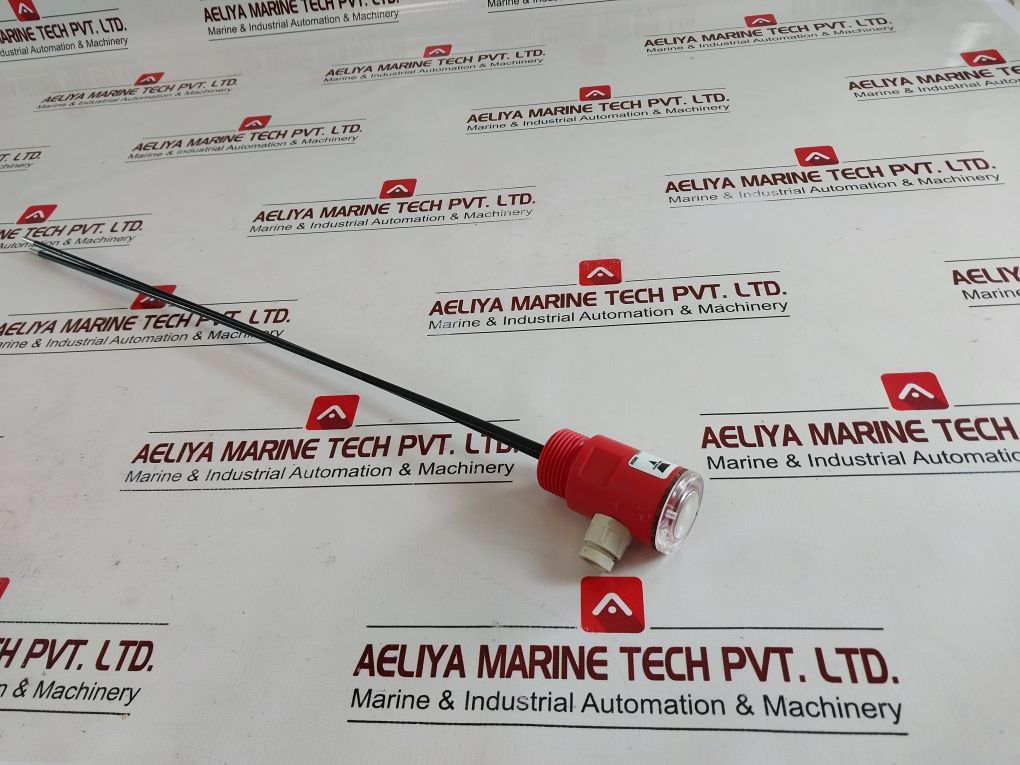

The VPC210 is streamlined and compact to ensure it fits in narrow openings where standard sensors would be inappropriate.

2. Capacitive Sensor Technology:

It employs sophisticated capacitive sensing for precise measurement even through walls of non-metallic containers. It detects conductive and non-conductive materials with equal ease.

3. Plug-and-Play Convenience:

With simple plug-and-play installation and low calibration needs, the VPC210 provides genuine plug-and-play convenience for operators and system integrators.

4. LED Status Indicators:

Integrated LED indicators provide real-time visibility into the status of the sensor for reduced maintenance troubleshooting time.

5. High Sensitivity and Accuracy:

The sensor is capable of sensing very low levels of liquid or granular solids and thus is suitable for precision applications.

6. Durable Build Quality:

Built to operate in industrial environments, the VPC210 is designed to handle high temperatures, vibrations, and chemical or moisture exposure.

Applications of the VPC210 Level Sensor

The Carlo Gavazzi VPC210 can be applied to a variety of industries, including:

Food and Beverage: To monitor liquid levels in processing tanks, mixers, and dispensers.

Pharmaceuticals: Reliable level measurement in sterile and high-purity applications.

Water Treatment Plants: To avoid dry-run or overflow in reservoirs and tanks.

HVAC Systems: To control condensate levels in cooling towers or air-handling units.

Chemical Processing: Best suited for aggressive or dangerous fluids where non-contact measurement is crucial.

Agriculture: To monitor feed and water levels in automated farm equipment.

Benefits Over Traditional Sensors

In contrast to mechanical float switches or ultrasonic sensors, the VPC210 does not use moving parts or sophisticated echo detection, and as a result is:

More robust: No moving components result in less wear and tear.

Highly versatile: Suitable for both liquids and solids, conductive or non-conductive.

Less maintenance: Less calibration and no internal contact with the medium.