| Attribute | Value |

|---|---|

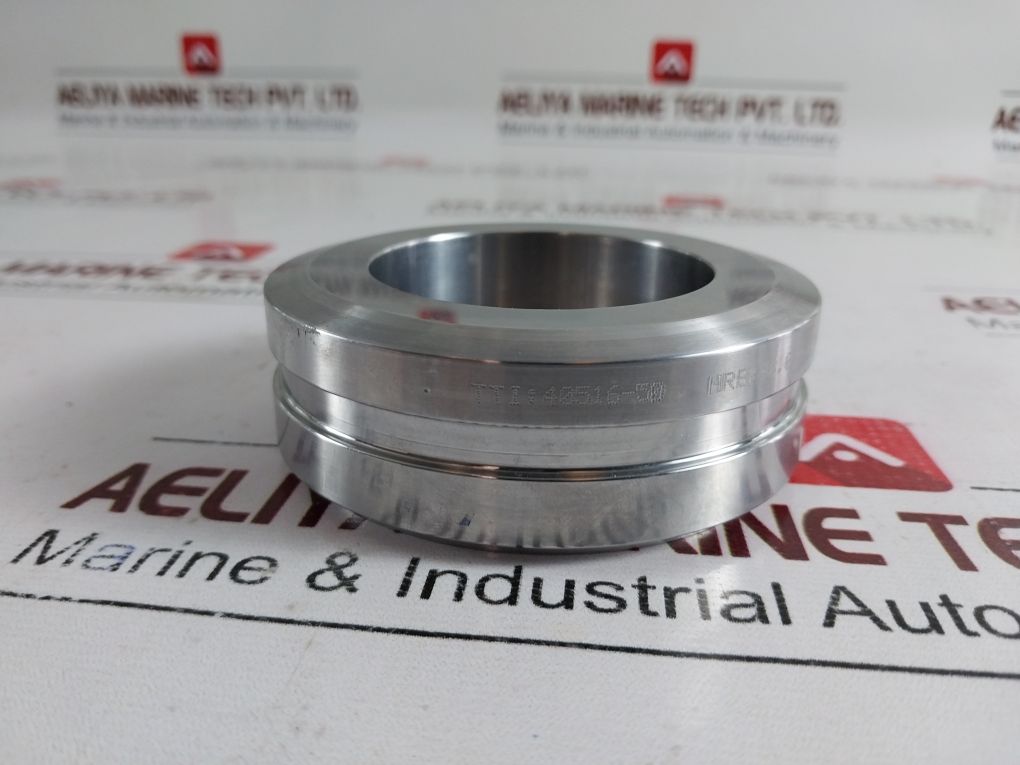

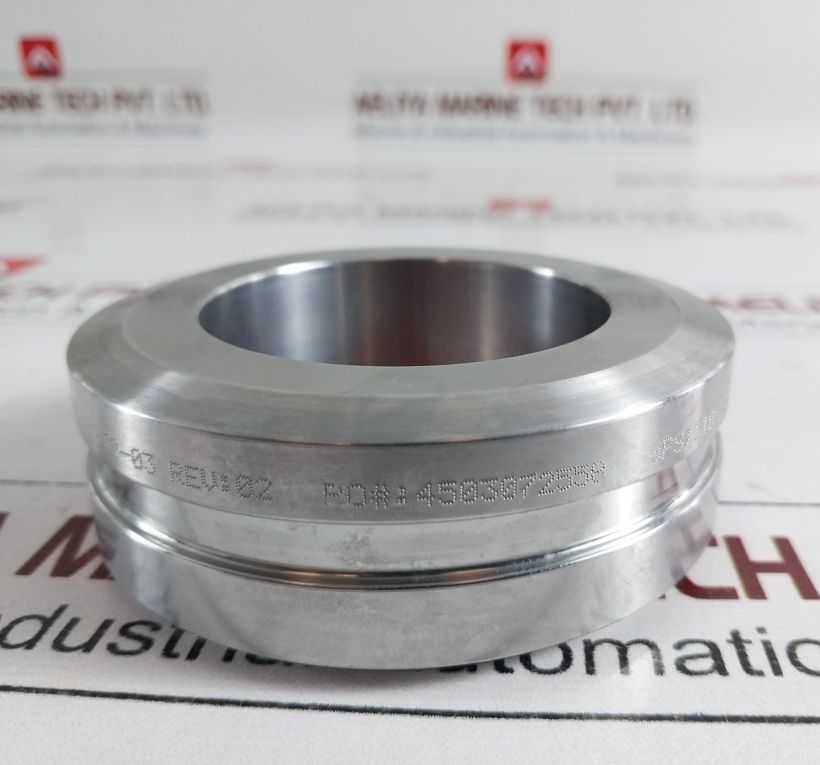

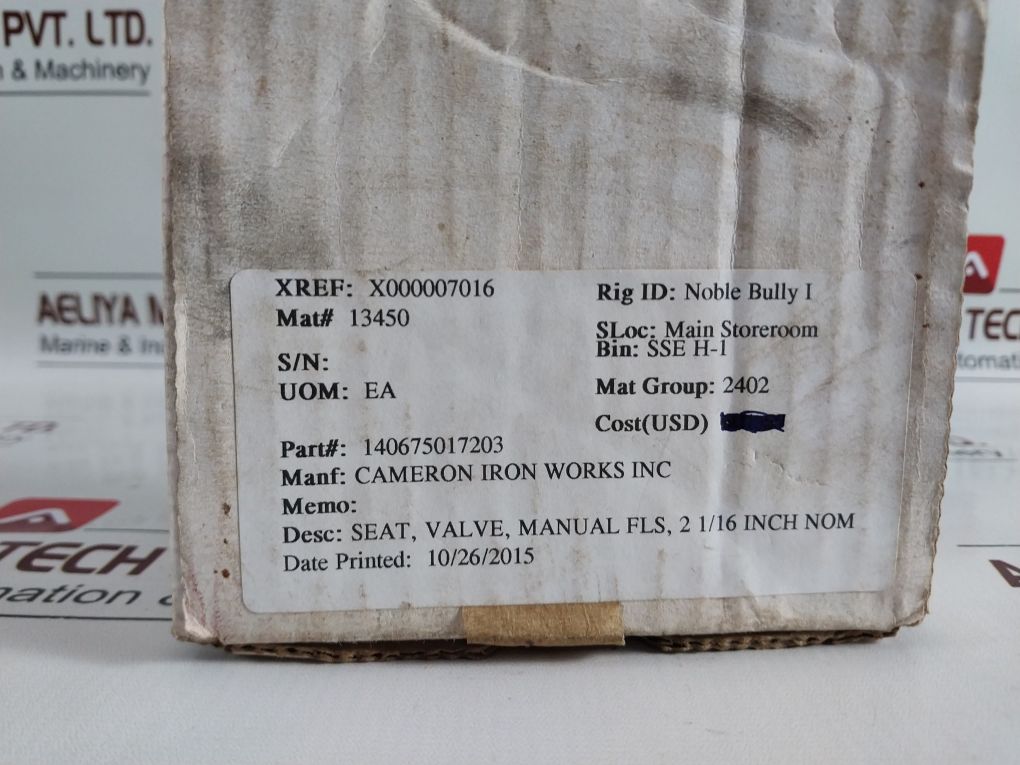

| Cameron | 140675-01-72-03 Valve Seat |

| Manufacturer | Cameron Iron Works Inc |

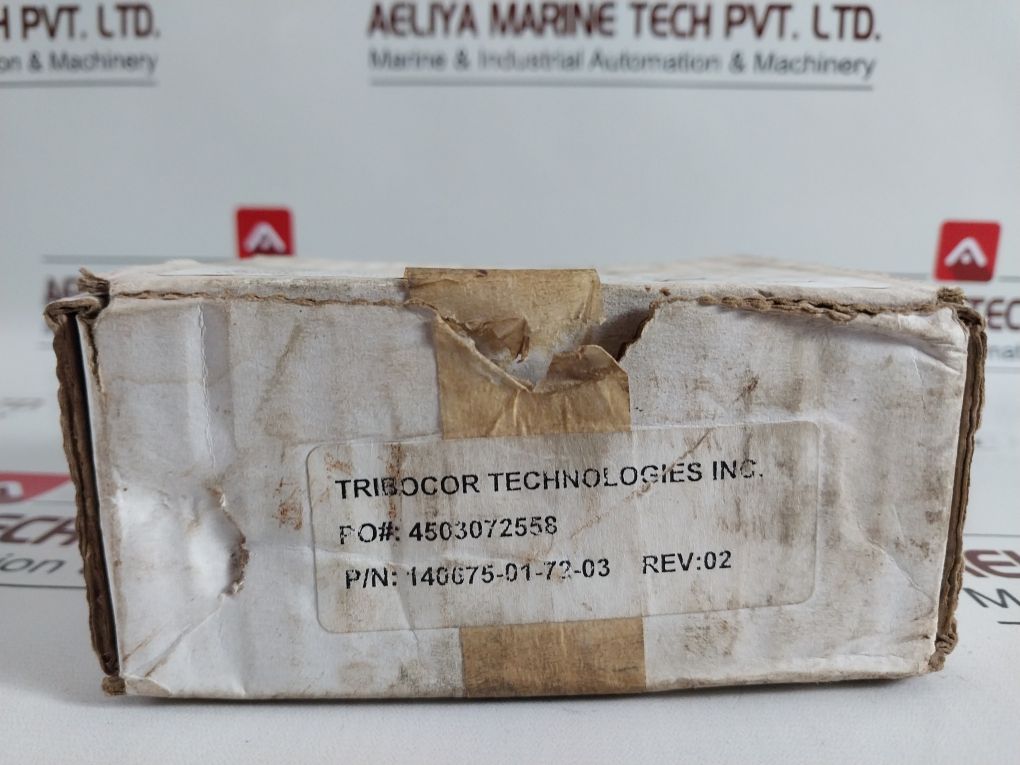

| Tti | Tribocor Technologies Inc. |

| Hrb | 96.0 |

| H/n | 253920 |

| P/n/part | 140675-01-72-03 |

| Revision | 02 |

| Wps | 110 |

| Description | Seat, Valve, Manual Fls, 2 1/16 Inch Nom |

| Xref | X000007016 |

| Mat | 13450 |

| Weight | 750 Gm |

| Ref No | 64096 |

Understanding Cameron 140675-01-72-03 Valve Seat

The valve seat is of great importance because it controls flow and pressure. The Cameron 140675-01-72-03 Valve Seat is created to be so strong that leakages are entirely avoided, along with long life.

Key Features

✔ Robust Material: Made from sturdy alloys or the strongest stainless steel for longer shelf life.

✔ Accurate Machining: Eliminates seepage fluids and enhances functional performance.

✔ Corrosion & Wear Resistance: Suitable for high-pressure and high-temperature applications.

✔ OEM Compatibility: Designed to fit Cameron valves, so it can be easily installed.

✔ Improved Performance: It prevents valve seat damage, which results in less maintenance and increased system reliability.

Applications of Cameron 140675-01-72-03 Valve Seat

This valve seat is used in most industries because of its resistance to extreme conditions. Some of its main applications are as follows:

1. Oil & Gas Sector

Valve seats are crucial in the oil & gas sector to maintain pipeline, drilling rig, and processing plant pressure control. The Cameron 140675-01-72-03 Valve Seat operates leak-free, thereby cutting the recurrence of downtime, ensuring smooth fluid flow.

2. Petrochemical & Refinery Plant

Refineries operate under extreme temperatures and corrosive environments. This valve seat provides excellent resistance to aggressive chemicals and high-pressure steam, making it a reliable choice for petrochemical applications.

3. Power Plants & Energy Sector

From thermal power plants to hydroelectric stations, efficient valve seating is necessary to maintain turbine and boiler operations. Cameron’s precision-engineered valve seats ensure reliable pressure regulation in these demanding environments.

4. Manufacturing & Heavy Industries

For example, in steel plants and units of chemical processing, these robustly constructed valve seats do not leak, enhance safety, and increase operational efficiencies.

Why Cameron 140675-01-72-03 Valve Seat?

Selecting a suitable valve seat is integral to upholding efficiency and longevity. Here’s why the Cameron 140675-01-72-03 Valve Seat is special:

✅ Proven Track Record: Used around the globe in high-performance applications.

✅ High-Quality Performance Lifetime: Withstands harsh conditions and repeated usage without any degradation.

✅ OEM-Approved Quality: Factory-crafted to meet Cameron’s strict standards for quality.

✅ Cost-Efficiency: Saves on maintenance and replacement costs over time.