| Attribute | Value |

|---|---|

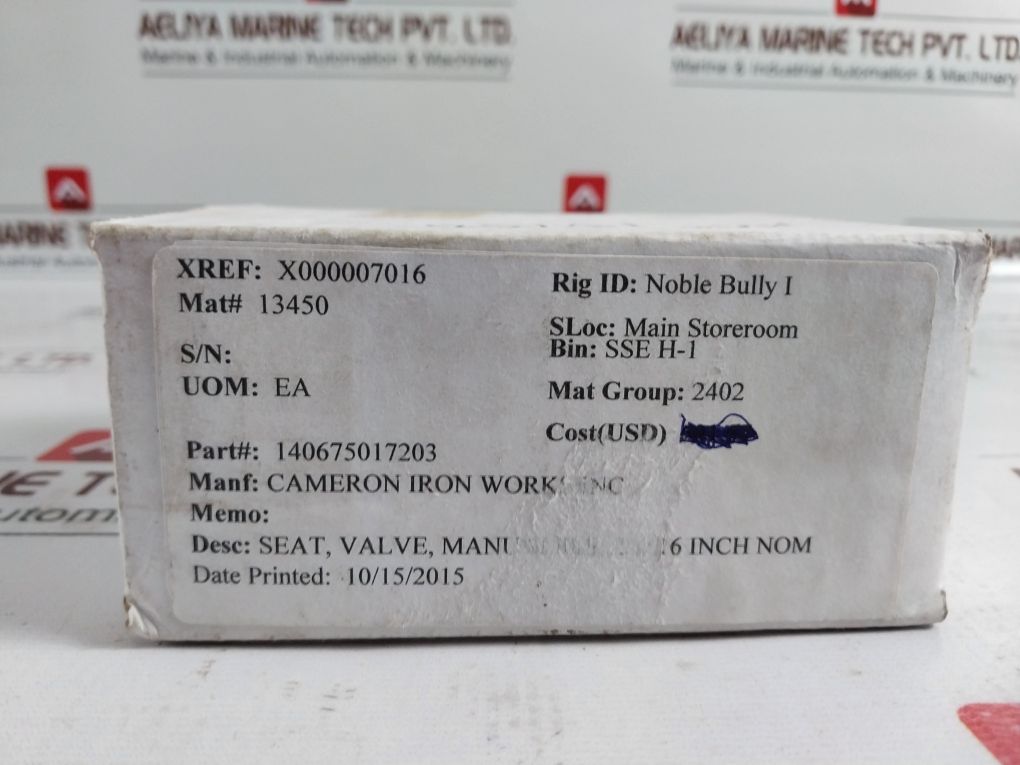

| Manufacturer | Cameron Iron Works Inc |

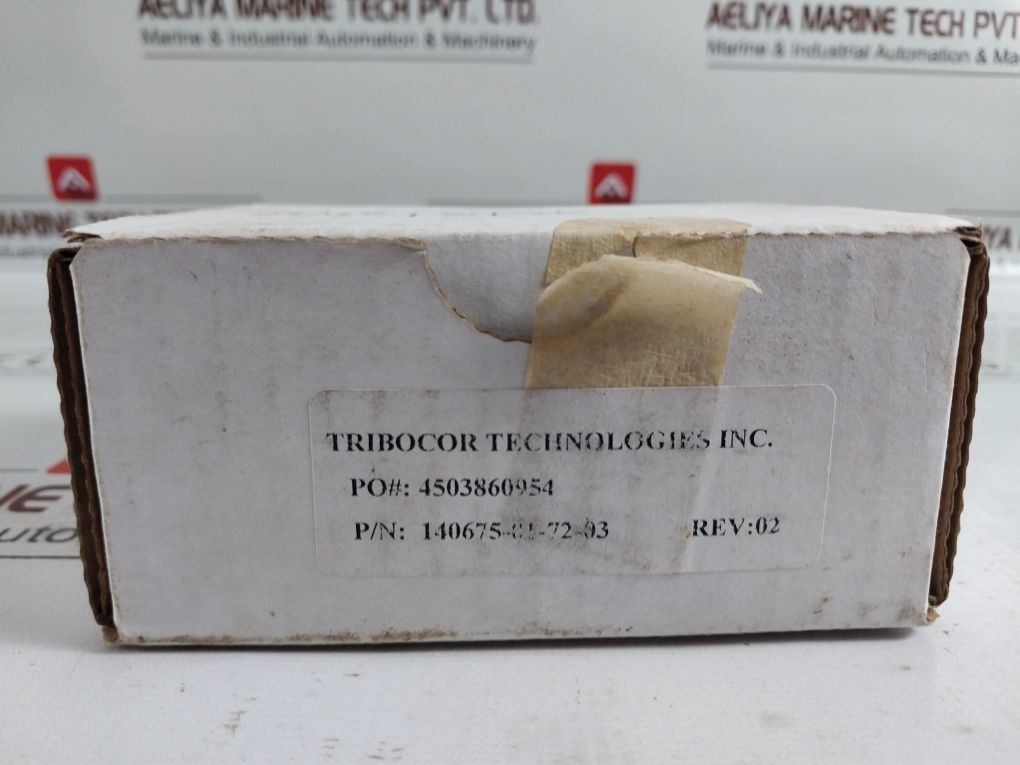

| TTI | Tribocor Technologies Inc. |

| HRB | 94.0 |

| H/N | 306523 |

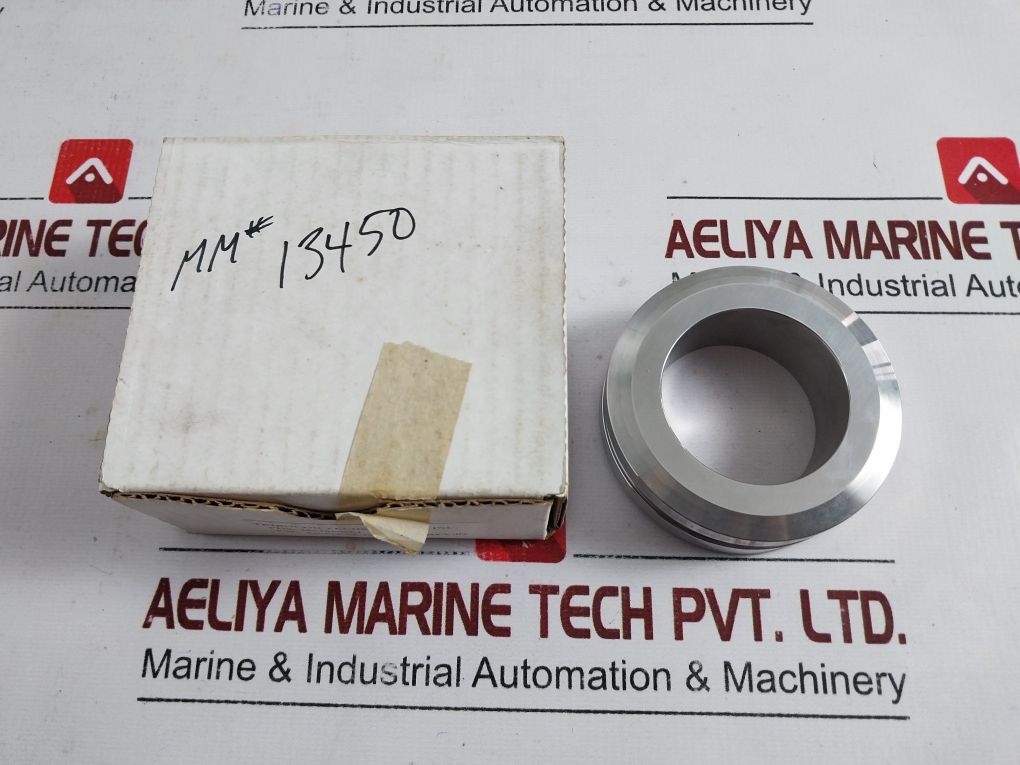

| Part Number | 140675-01-72-03 |

| Revision | 02 |

| Description | Seat, Valve |

| Cross Reference | X000007016 |

| Material Number | 13450 |

| Weight | 750 Gm |

| Reference Number | 64098 |

Key Features and Specifications

Precision Engineering- The unit is made to meet high industry standards for reliable fluid flow control.

High-Quality Materials- It is made of corrosion-resistant materials to work well under harsh environments.

Optimized Flow Control- It is designed to have the least possible pressure drop while maximizing its performance.

Durability and Reliability- Capable of withstanding extreme conditions that ensure extended operational life.

Rev 02 Enhancements- The latest revision included improved sealing technology for better leakage prevention.

Applications of the Cameron 140675-01-72-03 Seat Valve

The seat valve is applied in various industrial industries, such as:

1. Oil & Gas Industry

- Seat valves are applied in drilling rigs, pipelines, and refinery systems to control fluid movement.

- Ensure safety and efficiency in high-pressure applications.

2. Power Generation

- Help in the regulation of steam and cooling water flow in power plants.

- Enhance efficiency and prolong the life of equipment.

3. Chemical Processing

- Prevent contamination and ensure controlled chemical flow.

- Corrosive resistant, which is ideal for selection.

4. Water Treatment Plants

- Regulation of the liquid flow is aided in the treatment of waste.

- Efficient and smooth functioning of the filter and purification.

Benefits of the Cameron 140675-01-72-03 Seat Valve

1. Best Performance

It has high accuracy engineering which helps the valve in maintaining reliable operation and prevents its downtime with minimized maintenance costs.

2. Longer Lifespan

It offers excellent resistance to wear and corrosion, as well as very good durability at extreme conditions by the use of high-grade material.

3. Easy Maintenance

Easy disassembling and servicing to minimize down times and save effort in terms of maintenance work.

4. Cost-Effective Solution

High efficiency and longer service life give it a long-term cost effectiveness in industrial operations and reduce its replacement and repair costs in the long run.