| Attribute | Value |

|---|---|

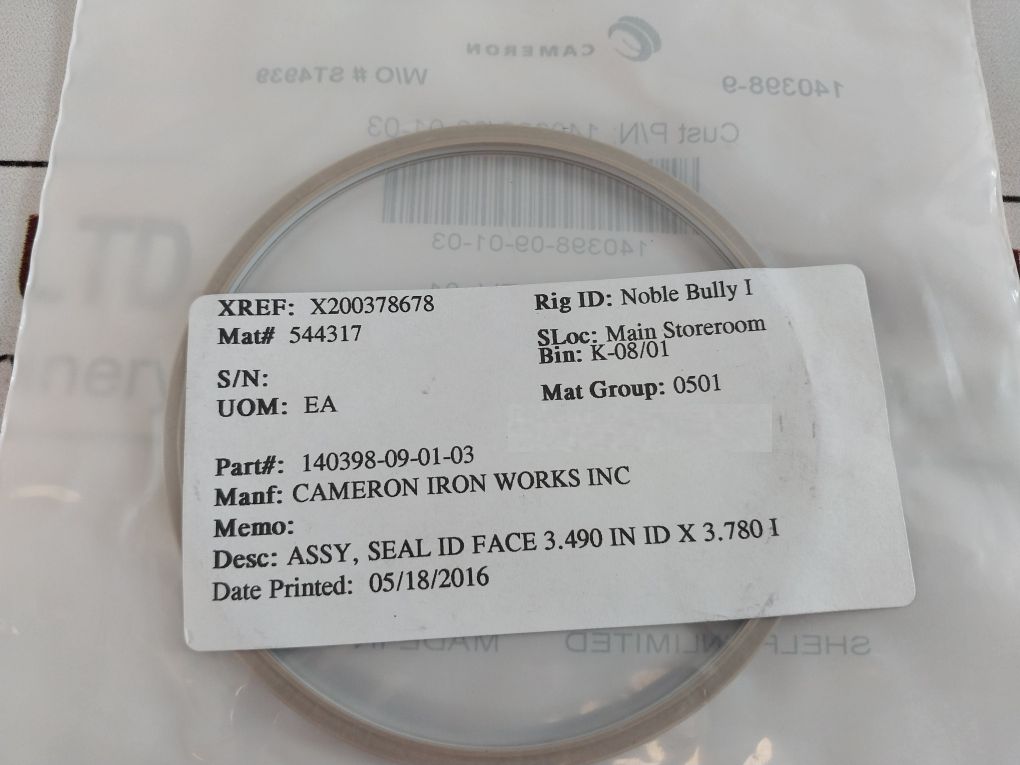

| Title | Cameron 140398-09-01-03 Face Seal & Seal Ring Insert Assy |

| Manufacturer | Cameron Iron Works Inc |

| Xref | X200378678 |

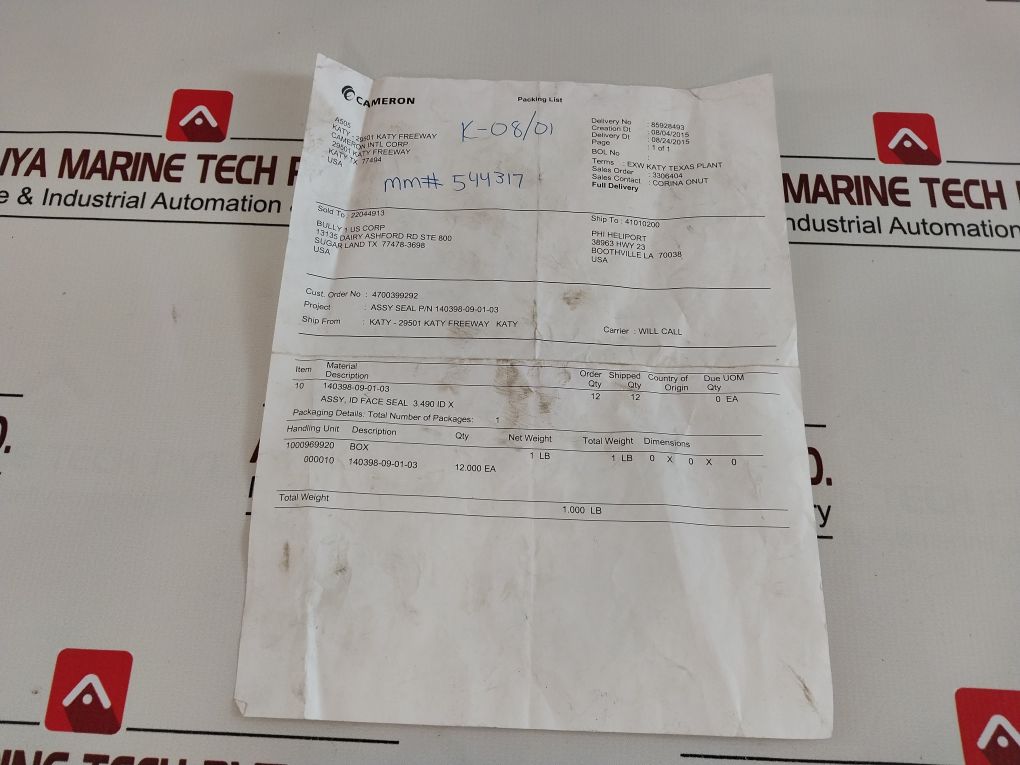

| Material No. | 544317 |

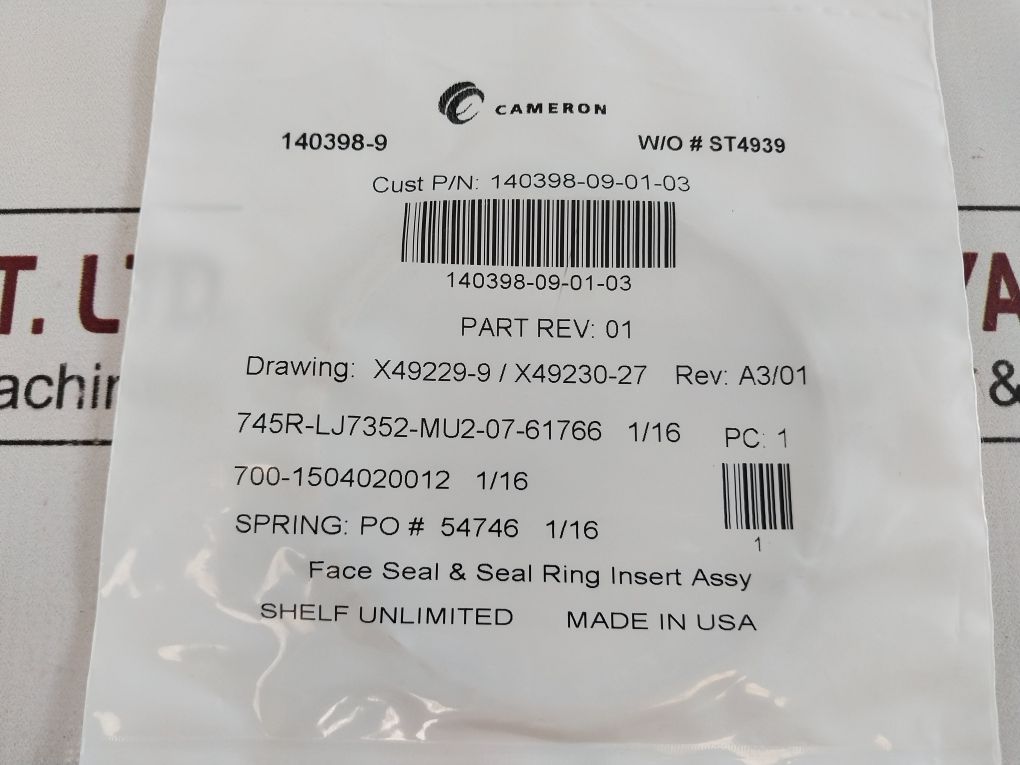

| Part No. | 140398-09-01-03 |

| Description | Assy, Seal Id Face 3.490 In Id X 3.780 I / 140398-9 |

| Part Revision | 01 |

| Revision | A3/01 |

| Additional Codes | 745r-lj7352-mu2-07-61766 700-1504020012 |

| Item Type | Face Seal & Seal Ring Insert Assy |

| Country of Origin | Made in USA |

| Weight | 50 gm |

| Condition | New (10 Pcs) |

| Ref No. | 60155 |

What is the Cameron 140398-09-01-03 Face Seal & Seal Ring Insert Assembly?

The Cameron 140398-09-01-03 is a precision-machined sealing element for applications in valves, flow control systems, subsea drilling equipment, blowout preventers, and high-pressure industrial assemblies.

It comprises :

Face seal – providing metal-to-metal or elastomeric-assisted sealing

Seal ring insert assembly: provides secondary support, structural integrity, and better leak protection.

This seal assembly was designed by Cameron, one of the leading names in the field of oil & gas and industrial engineering. It helps in pressure containment, fluid separation, and long-term operational safety.

Key Features

1. High-Pressure Sealing Performance

Designed to bear heavy loads, extreme pressures, and dynamic operational cycles without deformation or failure.

2. Construction from Premium Grade Material

Manufactured from corrosion-resistant, high-strength alloys compatible with oil, gas, chemicals, and aggressive industrial fluids.

3. Precision Machined Tolerances

Cameron parts are manufactured to world-class machining standards to provide proper sealing, minimal wear, and consistent field performance.

4. Leak-Proof Reliability

The combined face seal + ring insert design ensures zero leakage even at fluctuating temperatures or in high-pressure scenarios.

5. Long Operational Life

Built to resist abrasion, thermal fatigue, and chemical degradation-reducing maintenance frequency across the board.

6. Suitable for Hazardous & Offshore Environments

For systems subject to seawater, drilling mud, hydrocarbons, and abrasive contaminants.

7. Compatible with Cameron Wellhead & Valve Assemblies

Perfectly fits OEM design parameters for easy replacement, repair, and integration into existing equipment.

Applications

Cameron 140398-09-01-03 assembly is used in many applications, including:

1. Oil & Gas Wellhead Systems

Guarantees tight sealing in high-pressure wellhead equipment.

2. Blowout Preventer (BOP) Units

Avoiding leakage and ensuring pressure control are critical during drilling operations.

3. Offshore & Subsea Drilling Structures

Designed for hostile deep-sea environments requiring maximum corrosion resistance.

4. Control Valves & Actuator Systems

Ensures smooth, leak-proof operation of valve assemblies in both industrial and marine applications.

5. Industrial Pumps & Compressors

Maintains fluid separation and prevents leakage inside high-speed rotating machinery.

6. Marine & Shipboard Machinery

Applied in high pressure hydraulic systems, engine room components and safety-critical assemblies.

7. Pressure-Control & Flow-Management Equipment

Provides stable sealing for equipment that requires high reliability.

Why Choose the Cameron 140398-09-01-03 Face Seal & Seal Ring Insert Assembly?

Choosing the correct sealing component is paramount to the protection of expensive machinery and ensuring operational safety. Here’s why this Cameron seal stands out:

1. OEM Quality You Can Trust

As an original Cameron component, it delivers perfect compatibility and reliable engineering excellence.

2. Improved Safety and System Integrity

A strong sealing assembly minimizes leakage, precludes cross-contamination, and maintains pressure stability.

3. Reduces Downtime & Maintenance Costs

Longer life means fewer failures, less repair time, and consequently fewer operational disruptions.

4. Ideal for Demanding Environments

This seal assembly tackles extreme conditions, ranging from marine engineering to offshore drilling, with ease.

5. Reliable Replacement Part

Perfect for refurbishing or restoring the performance of older oilfield or industrial equipment.

6. Trusted in Global Industries

Used by leading energy companies, marine operators, and heavy-industrial plants all over the world.