| Attribute | Value |

|---|---|

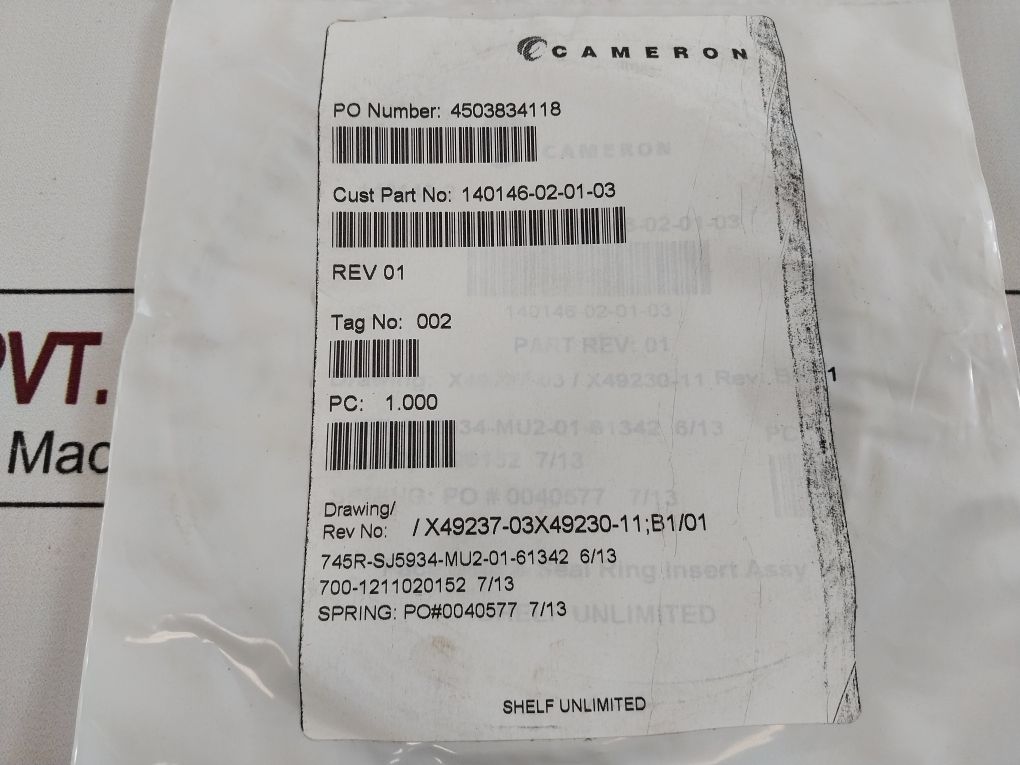

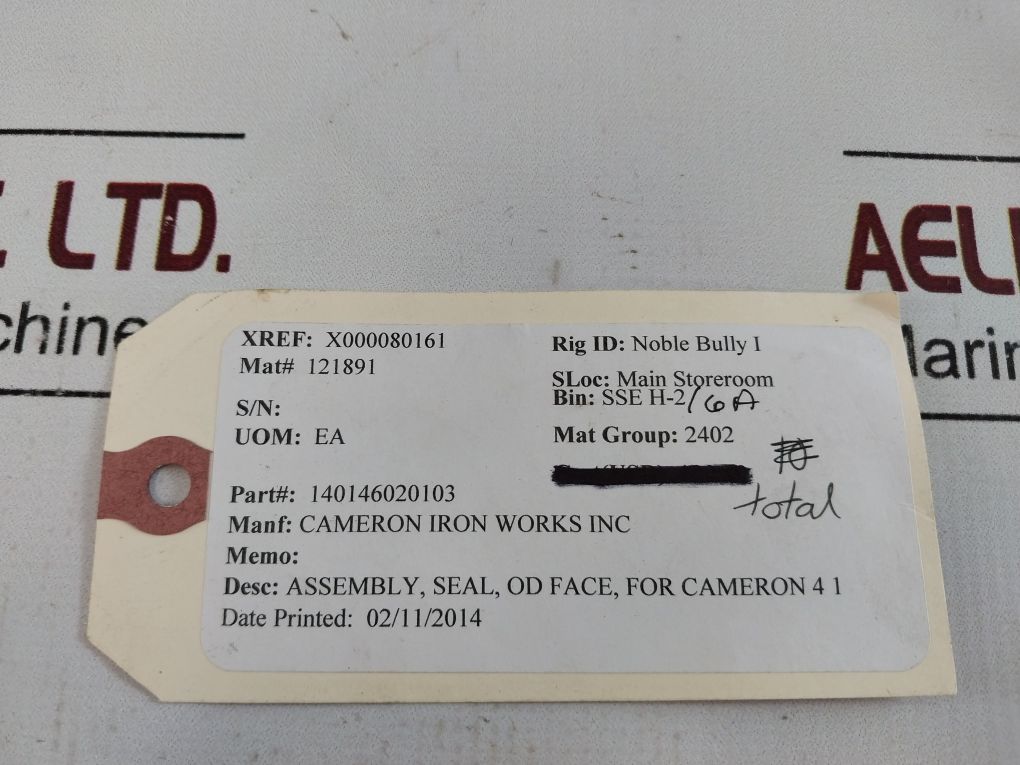

| Product Name | Cameron 140146020103 Seal Assembly |

| Manufacturer | Cameron Iron Works Inc |

| Xref | X000080161 |

| Material Number | 121891 |

| Part Number | 140146020103 |

| Description | Assembly, Seal, OD Face, For Cameron 4 1 |

| Revision | 01 |

| Additional Code | 745r-sj5934-mu2-01-61342 |

| Code | 700-1211020152 |

| Weight | 50 Gm |

| Condition | New (8 Pcs) |

| Reference Number | 60096 |

What is the Cameron 140146020103 Seal Assembly?

The Cameron 140146020103 Seal Assembly is a high-performance sealing unit designed to serve in pressure control, flow control, and drilling system equipment. This seal assembly is manufactured by Cameron, a globally recognized leader in oilfield solutions, and it serves as an important seal that prevents leakage of fluid or gas in high-pressure systems.

Typical assembly components include precision-machined elements like elastomers, sealing rings, gaskets, and metal housings that are designed to withstand extreme environmental conditions.

Application range: from wellheads through blowout preventers, valves, and actuators, the Cameron seal provides assurance of reliable operation with a tight and durable seal even against extreme fluctuations in temperature or pressure.

Key Features of the Cameron 140146020103 Seal Assembly

1. High-Pressure Leak-Proof Design

Designed to keep a tight seal in high-pressure applications, thereby ensuring operational safety while minimizing leakage risks.

2. Premium-grade materials

Made from premium elastomers and metals that are engineered to withstand wear, corrosion, and chemical exposure.

3. Precision Engineering

Manufactured with tight tolerances and exact specifications for superior sealing efficiency and equipment compatibility.

4. Thermal and Chemical Resistance

Works effectively in highly extreme temperature applications, aggressive fluids, and harsh environmental conditions.

5. Long Operational Life

The durability design aims to decrease frequency and extend uptime in continuous operation under heavy-duty conditions.

6. Easy Integration and Replacement

Compatible with a broad range of Cameron equipment and industry-standard sealing configurations, enabling rapid installation.

Applications of the Cameron 140146020103 Seal Assembly

Oil & Gas Drilling Systems

Employed in wellheads, drilling BOP systems, and production equipment where high-pressure sealing is required.

Flow Control Equipment

Mounted in the valves, actuators, and manifolds for leak-free fluid movement in the system.

Pressure Control Systems

Ensures safe and reliable sealing in high-pressure environments encountered in upstream and midstream operations.

Petrochemical Processing Units

Supports the sealing requirements in pumps, pipelines, and machinery handling chemically reactive substances.

Industrial machinery

Used in general industrial equipment for applications that require rugged sealing performance in hydraulic or pneumatic systems.

Spare Part Replacement and Maintenance

Great for maintaining legacy Cameron systems and continuing smooth operations with the right part replacements on time.

Why Choose the Cameron 140146020103 Seal Assembly?

Trusted Cameron Quality

Cameron is a Schlumberger company globally recognised for the manufacture of high-reliability components for drilling, production, and pressure control operations.

Engineered for Harsh Conditions

This seal assembly is designed to work under extreme temperatures, abrasive fluids, and high mechanical stress.

Improves system safety

Reduces the risk of leak-related failures, protects the personnel, equipment, and immediate surroundings.

Improves Operational Efficiency

Dependable sealing ensures maximum performance of systems, minimizes downtime, and prolongs equipment life.

Cost-Effective Maintenance

With durable materials and design, long-term operational costs are reduced since the need for frequent replacements is lessened.

Industry Wide Compatibility With multiple

Cameron systems, the Cameron 140146020103 Seal Assembly fits into place with ease and can be reliably used in facilities that make use of Cameron technologies.