| Attribute | Value |

|---|---|

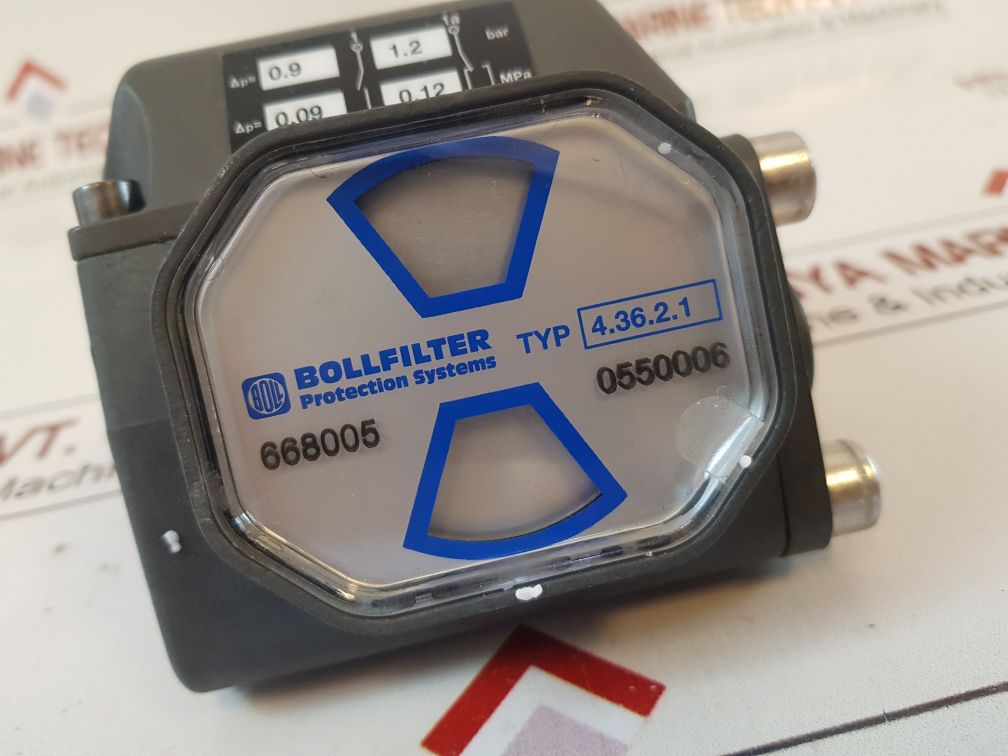

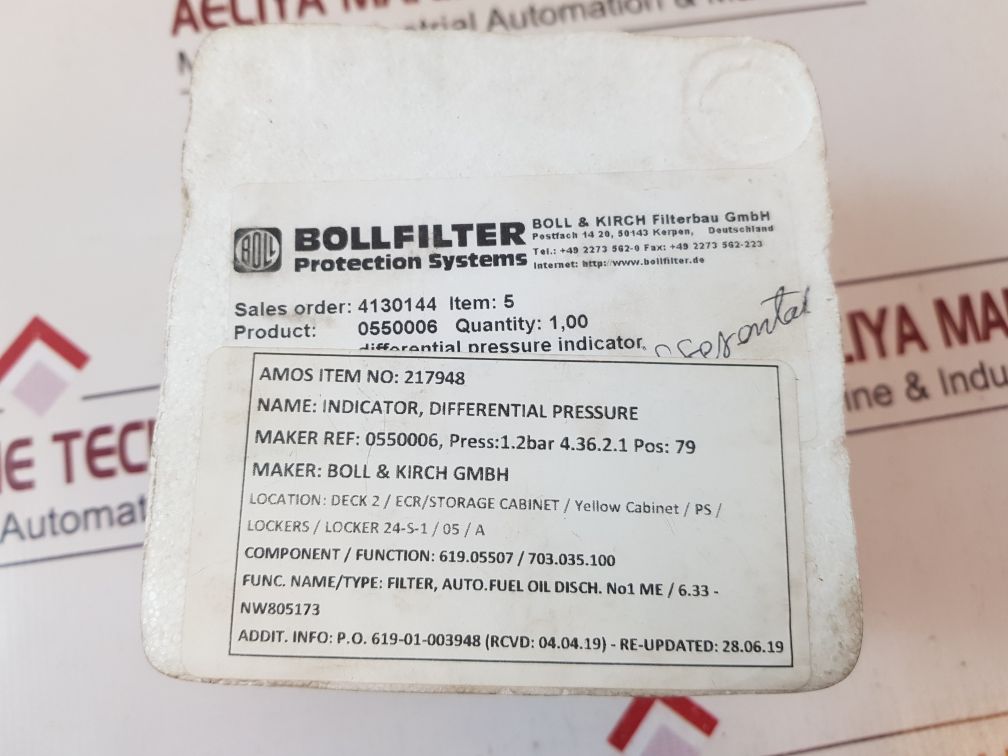

| Product Name | BOLLFILTER 4.36.2.1 DIFFERENTIAL PRESSURE INDICATOR |

| BOLLFILTER Protection Systems | BOLL & KIRCH FILTERBAU GMBH |

| Product No. | 0550006 |

| Differential Pressure | ΔP= 0.9 – 1.2 BAR / ΔP= 0.09 – 0.12 MPA |

| AMOS Item No. | 217948 |

| Indicator Name | INDICATOR, DIFFERENTIAL PRESSURE |

| Maker Reference | 0550006, PRESS: 1.2 BAR |

| Maker | BOLL & KIRCH GMBH |

| Component/Function | 619.05507 / 703.035.100 |

| Function Name / Type | FILTER, AUTO, FUEL OIL DISC. NO1 ME / 6.33-NW805173 |

| Weight | 700 GM |

| Reference No.(S) | 51123 |

What Is a Differential Pressure Indicator?

A differential pressure indicator (DPI) is a monitoring device used to measure the difference in pressure between the inlet and outlet of a filtration system. It indicates when a filter has become clogged or requires its need for maintenance, thus averting potential damage to the machineries and ensuring effective running.

The BOLLFILTER 4.36.2.1 is one of the quality differential pressure indicators developed especially for BOLL & KIRCH filtration system usage; it has been a high-preferred device in various industries.

Main Features of the BOLLFILTER 4.36.2.1 Differential Pressure Gauge

1. High Precision Monitoring

BOLLFILTER 4.36.2.1 has a capacity to monitor continuous pressure. It will notify an operator with immediate pressure alerts if the filter is clogged.

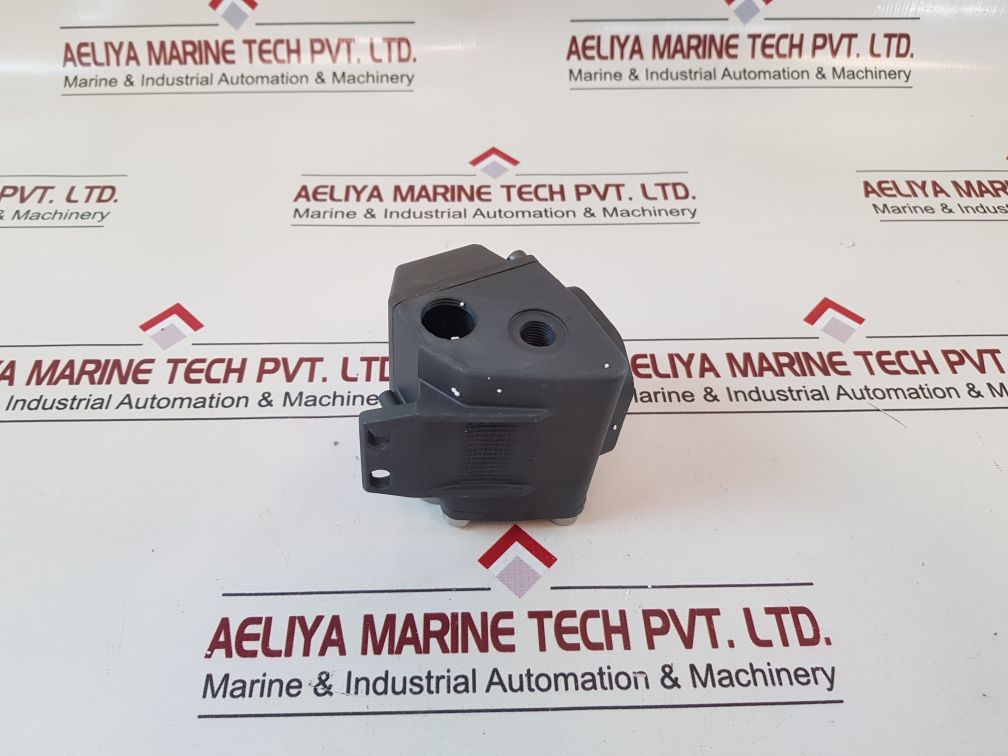

2. Rugged Construction

This DPI is constructed with high-grade materials that protect it from hostile environments, extreme temperatures, and aggressive fluids, which makes it ready for industrial applications.

3. Opto-electrical Signaling

There are two methods to notify the operators about pressure buildup: one is visual alerts and the other is electrical signals. These two ensure punctual replacement or cleaning of filters to ensure the system functions well.

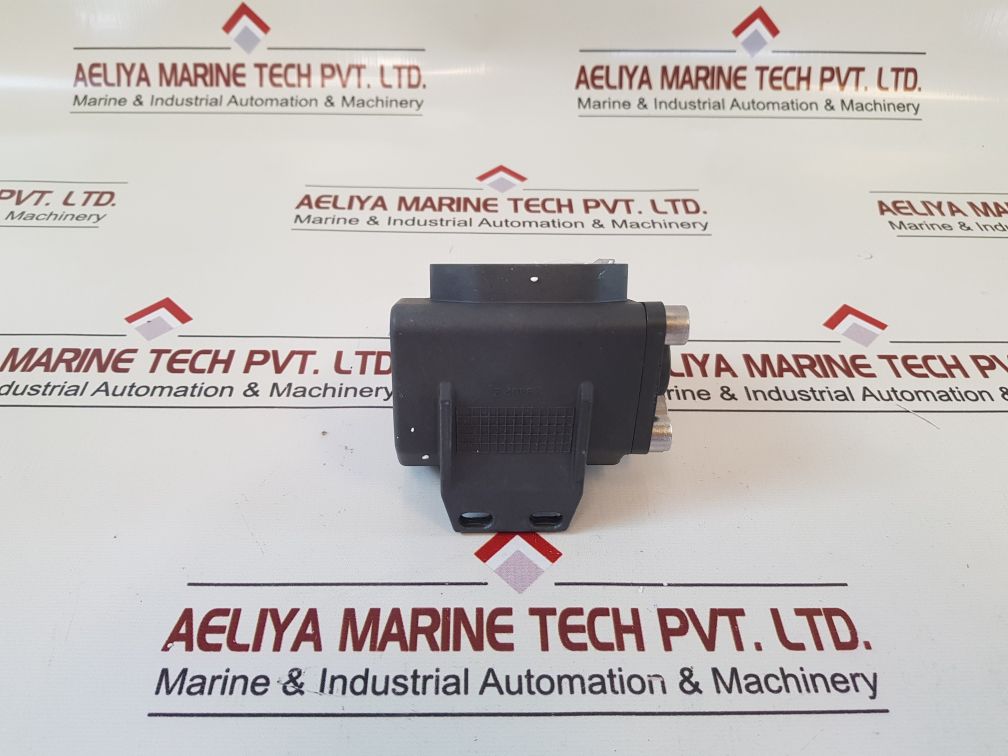

4. Easy Integration

This model is created to fit smoothly with the pre-existing BOLLFILTER systems, is easy to install, and needs minimal maintenance.

5. High Sensitivity and Reliability

It identifies minor changes in pressure, giving time for advance maintenance and prevents an unexpected break-down.

How Does the BOLLFILTER 4.36.2.1 Work?

The differential pressure indicator works by determining the pressure in both sides of a filter; when the filtration becomes clogged with debris, the pressure becomes higher. Such an increase causes the BOLLFILTER 4.36.2.1 to trigger warning mechanisms, for example, it can use visual display in colour or an electric signal that makes a connection at a control panel.

Operators can act promptly to clean or replace the filter to avoid increasing pressure buildup that may result in damage to pumps, valves, or equipment further downstream.

Benefits of using BOLLFILTER 4.36.2.1 Differential Pressure Indicator

✅Improved Filtration Efficiency

This ensures filters operate at the peak of performance as clogging is prevented.

✅Extended Equipment Life

Wear on pumps, engines, and hydraulic systems decreases; expensive equipment life is lengthened.

✅ Energy Savings

A blocked filter causes a system to work harder, and energy consumption is increased. Timely maintenance alerts help avoid unnecessary energy costs.

✅ Reduced Downtime

Possible filtration problems are identified before they lead to system failure, thereby saving businesses the expense of system shutdowns.

✅ Improved Safety

In critical industries like marine, power plants, and oil & gas, it ensures that the system is stable, and hazardous situations are avoided because of pressure surges.

Applications of BOLLFILTER 4.36.2.1 Differential Pressure Indicator

This indicator is widely used in various industries where precise filtration is essential.

Marine Industry: Protects fuel, lubrication, and ballast water systems.

Power Plants: Ensures clean water and oil filtration in turbines.

Oil & Gas Sector: Prevents contamination in fuel and hydraulic systems.

Chemical Industry: Keeps process fluids free of impurities.

Automotive & Heavy Machinery: Supports hydraulic and cooling systems.