| Attribute | Value |

|---|---|

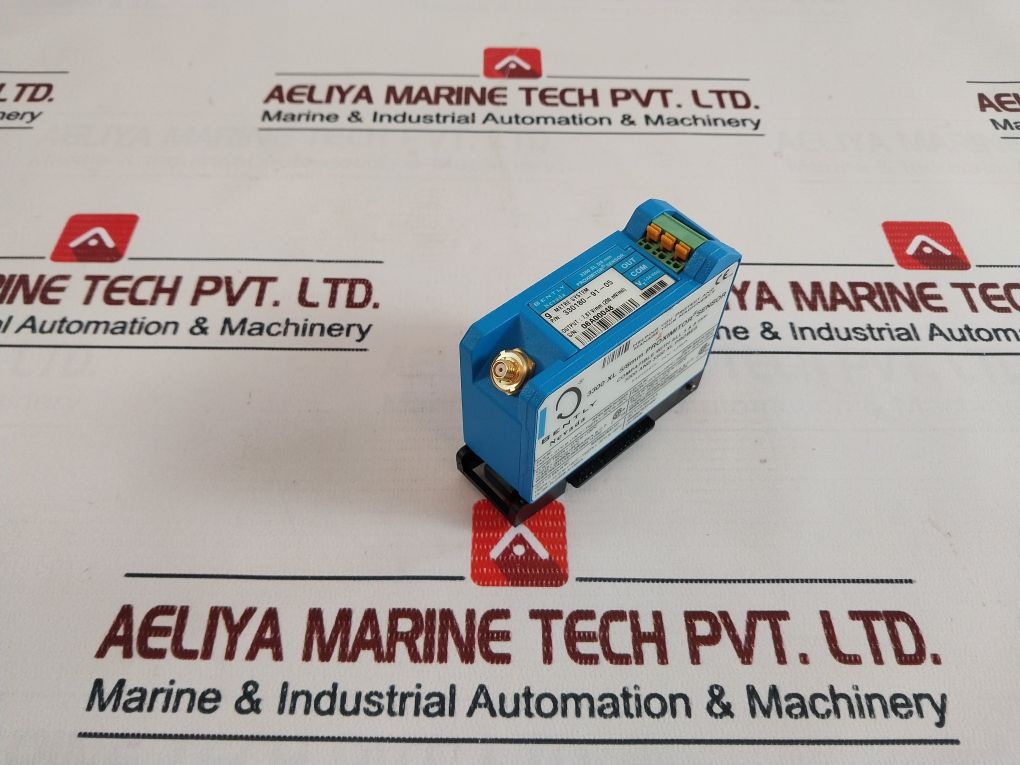

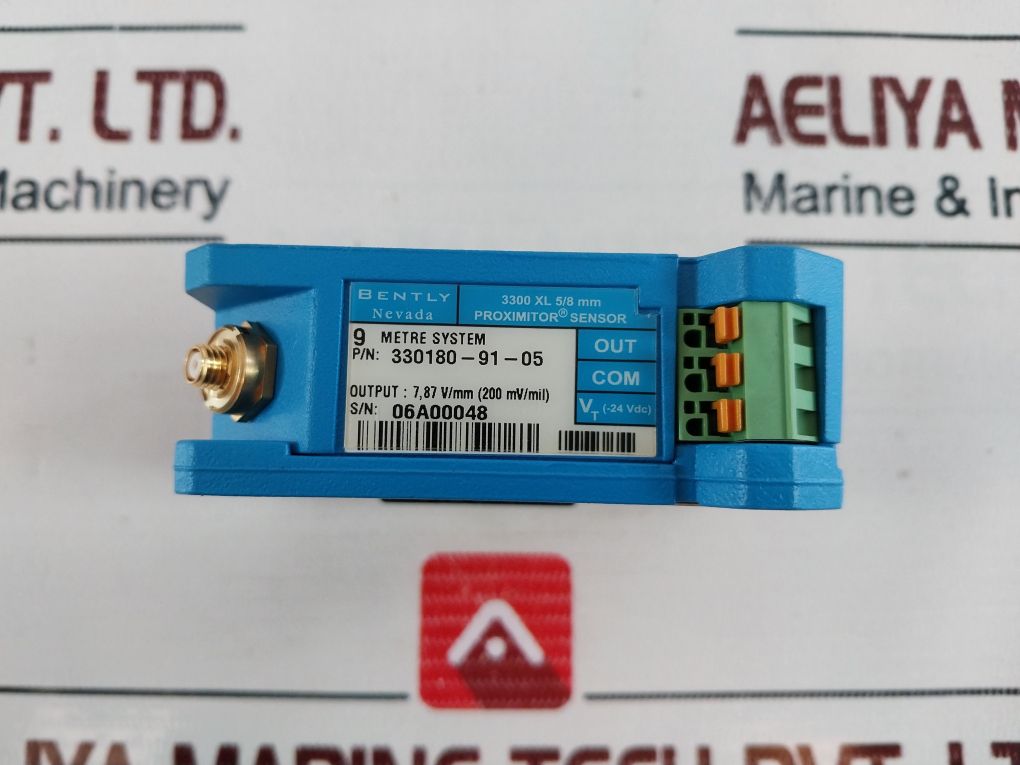

| Product Name | Bently Nevada 330180-91-05 Proximitor Sensor 3300 XL 5/8 mm |

| Brand | Bently Nevada |

| Model | 3300 XL 5/8 mm Proximitor Sensor |

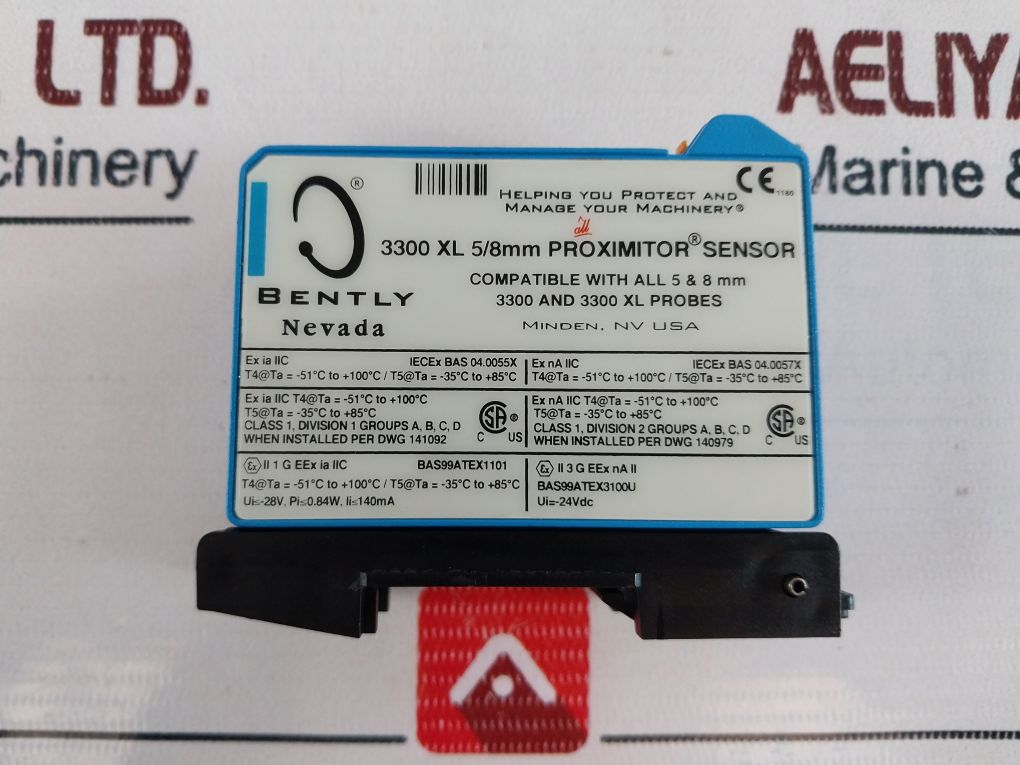

| Compatibility | Compatible with all 5 & 8 mm 3300 and 3300 XL Probes |

| System Length | 9 Metre System |

| Part Number (P/N) | 330180-91-05 |

| Output | 7.87 V/mm (200 mV/mil) |

| VT/UI | -24 VDC |

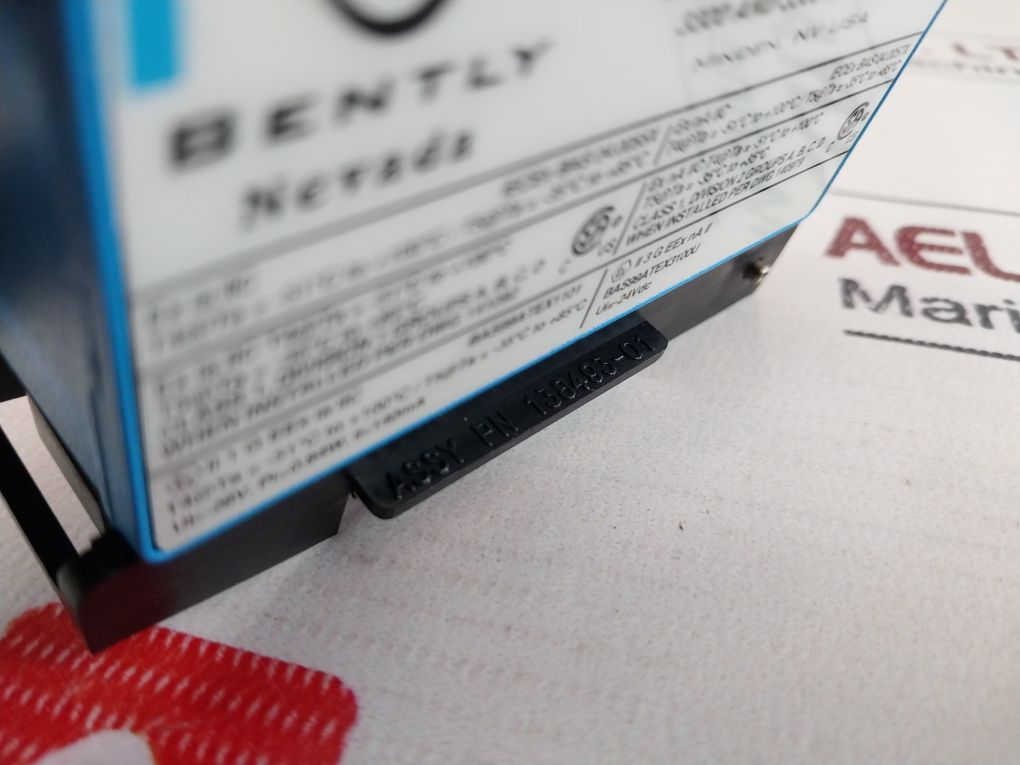

| Assembly Part Number | 138493-01 |

| Explosion Protection Markings | Ex ia IIC IECEx BAS 04.0055X Ex na IIC IECEx BAS 04.0057X |

| Temperature Ratings | T4 @ Ta = -51°C to +100°C T5 @ Ta = -35°C to +85°C |

| Hazardous Area Classification | Class 1, Division 2 Groups A, B, C, D II 1 G EEx ia IIC (BAS99ATEX1101) II 3 G EEx na II (BAS99ATEX3100U) |

| Electrical Ratings | Ui: 28V Pi: 0.84W Ii: 140mA |

| Country of Origin | USA |

| Weight | 250 gm |

| Reference No | 74356 |

What is the Bently Nevada 330180-91-05?

It’s a member of the 3300 XL 5/8 mm proximity transducer system, one of the most reliable in mission-critical machinery monitoring. It’s used to measure the displacement and vibration of rotating shafts and other moving parts with amazing precision.

The sensor is used in conjunction with a corresponding extension cable and proximitor (proximity probe driver) to give a full transducer system. In combination, they translate the physical travel of a machine component into an accurate electrical signal that may be sensed or recorded.

Features of the 330180-91-05 Proximitor Sensor

Part of the 3300 XL Series – An extremely reliable sensor system in machinery health monitoring.

5/8 mm Tip – Suits measurement of shaft vibration and displacement in small or critical areas.

Rugged and Reliable – Built to handle harsh industrial environments.

High Signal Stability – Provides stable readings, reducing downtime or false alarm.

Non-Contact Measurement – Lowers wear and enables safer long-term monitoring.

Technical Specifications

Model Number: 330180-91-05

Series: 3300 XL

Tip Diameter: 5/8 mm

Material Compatibility: Compatible with Bently Nevada proximitor and extension cables

Operating Environment: Harsh industrial and marine environments

Output: Proportional to distance voltage (non-contact measurement)

Usage: Shaft vibration monitoring, rotor position detection, and displacement analysis

Applications

The Bently Nevada 330180-91-05 sensor is an industry favorite where machine condition monitoring is a necessity. This is where it really excels:

Oil & Gas Equipment: On pumps, compressors, and turbines where real-time vibration monitoring is paramount.

Power Generation Plants: Aids in the detection of shaft misalignment or imbalance in generators and turbines.

Marine Engines: Guarantees the durability of high-load rotating equipment on ships.

Manufacturing Plants: Tracks bearings and gearboxes to lower unplanned maintenance.

Maintenance groups can avoid disastrous failures, prolong machinery lifespan, and keep higher levels of safety with this sensor system.

Why Select Bently Nevada?

Bently Nevada, a business of Baker Hughes, is a world leader in condition monitoring and machinery protection systems. Their sensors are renowned for their accuracy, reliability, and compatibility with sophisticated diagnostic equipment. Selecting a 3300 XL series sensor guarantees compatibility with most monitoring systems and control platforms.

Reviews

There are no reviews yet.