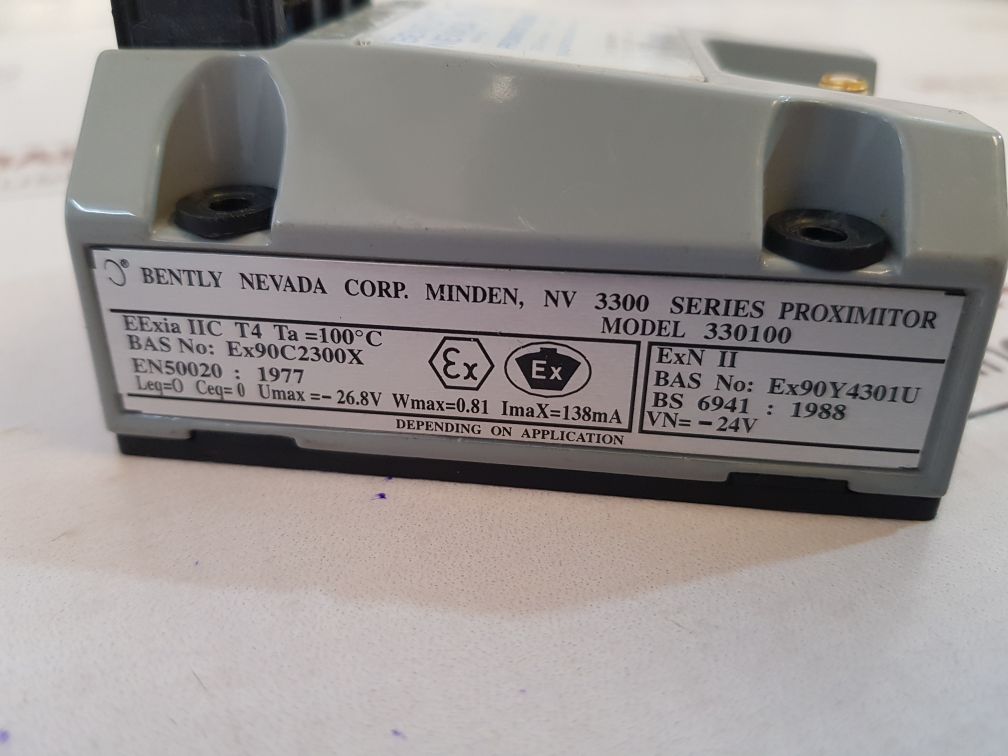

| Attribute | Value |

|---|---|

| Manufacturer | BENTLY NEVADA CORP. |

| Model | 330100 |

| Series | 3300 SERIES |

| Voltage | -24 VDC |

| Scale Factor | 200 MV/MIL (7.87 MV/µM) |

| Part Number | 330100-50-05 |

| System Length | 5 METRE |

| Certification | EEXIA IIC T4 TA= 100°C |

| Base No | EX90C2300X |

| Standard | EN50020: 1977 |

| LEQ | 0 |

| CEQ | 0 |

| UMAX | -26.8V |

| WMAX | 0.81 |

| IMAX | 138MA |

| Explosion Protection | EXN II |

| Base No | EX90Y4301U |

| Standard | BS 6941: 1988 |

| VN | -24V |

| Hazardous Location | CLASS I, DIVISION 1 EXIA GROUPS A,B,C,D CLASS I, DIVISION 2 GROUPS A,B,C & D |

| Temperature Code | T4A, TA=100°C, T5, TA=65°C |

| Country of Manufacture | MADE IN U.S.A. |

| Weight | 280 GM |

| Condition | USED 17 PCS |

| Reference No | 41969 |

Key Features of Bently Nevada 3300 Series 330100-50-05

High Precision Measurement: This sensor gives higher accuracy in determining shaft displacement and vibration.

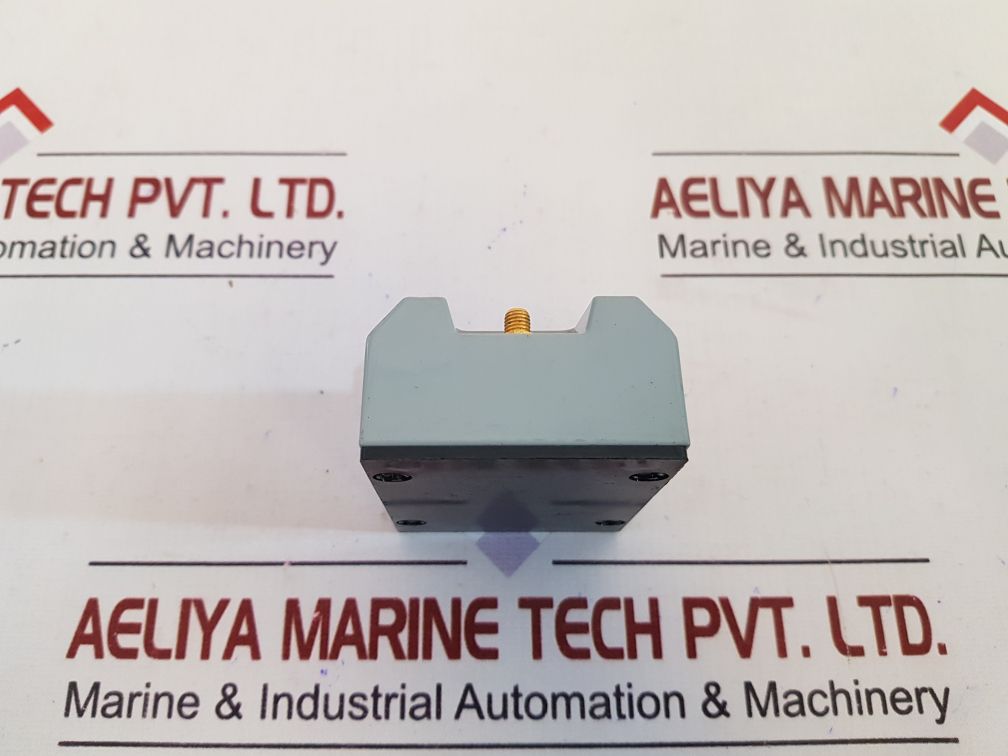

Durable Construction: It is designed for the rough industry environment and shall be expected to last long enough.

Non-Contacting Monitoring: The sensor works on proximity method by measuring without touching the target surface.

Industry Standards Compliance: The system is absolutely API 670 compliant, allowing its use in any industry setup.

Reliable Signal Transmission: It maintains a stable signal without interference, facilitating real-time monitoring.

Applications

The Bently Nevada 3300 Series 330100-50-05 is applied within various industries across the globe based on its strength in condition monitoring. Some of its key applications include:

Power Plants: Used to monitor turbines and generators continuously

Oil & Gas Industry: Useful in monitoring the compressors and pumps to prevent catastrophic failures.

Manufacturing Industry: Ensures proper running of rotatory equipment during industrial production.

Aerospace & Defense: Gives accurate readings in high-performance machinery.

Chemical Processing: Measures critical machinery in hazardous environments.

Advantages of the 330100-50-05 Proximity Sensor

Better Machine Protection: The early indication of wear and misalignment prevents expensive breakdowns.

Increased Equipment Life Cycle: Continuous monitoring minimizes over-wear and tear, leading to a longer machine life.

Maintenance Cost Saving: Preventive maintenance through real-time data saves on repair cost and time lost.

Improved Operational Safety: The machines run under optimal conditions, thus reducing the chances of accidents in general.

Ease of integration: It is compatible with most monitoring systems, hence straightforward installment.

Why Bently Nevada?

Bently Nevada is a globally recognized brand known for its high-quality condition monitoring solutions. Their 3300 Series sensors are trusted by industry leaders due to their precision, durability, and compliance with industry standards. The 330100-50-05 model continues this legacy by offering cutting-edge proximity sensing technology that enhances equipment reliability and efficiency.