| Attribute | Value |

|---|---|

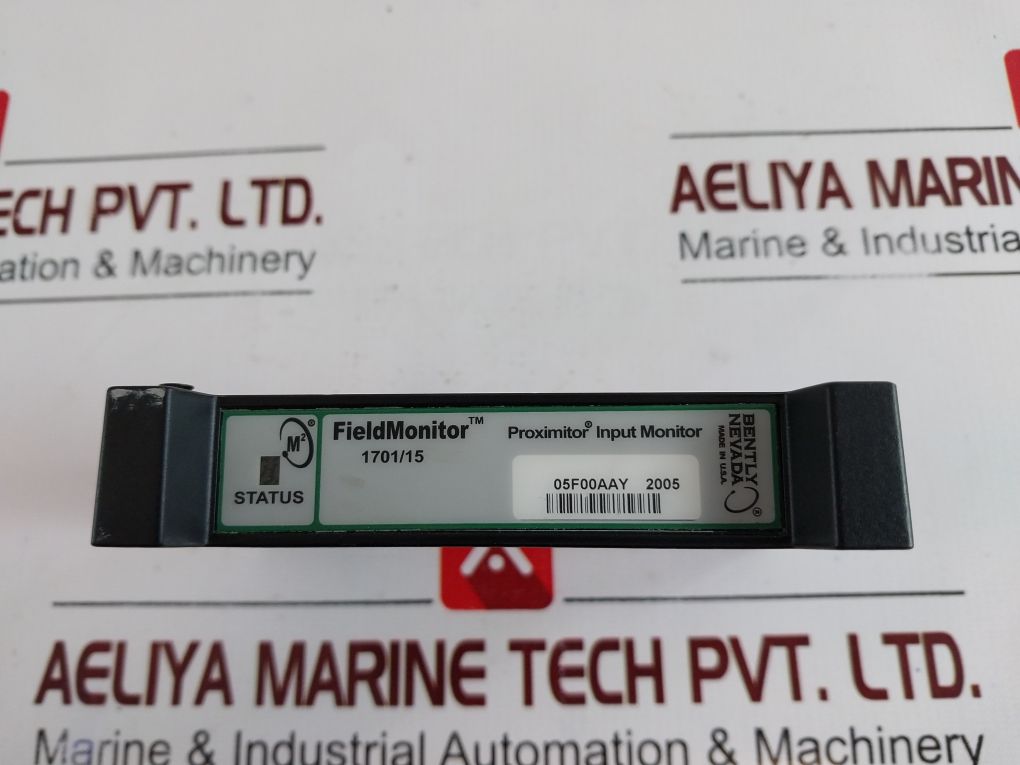

| Product Name | Bently Nevada 1701/15 Proximitor Input Monitor |

| Brand | Bently Nevada |

| Series | Fieldmonitor M² |

| Catalog Number | 1701/15 |

| Description | Proximitor Input Monitor |

| Part Numbers | 05f00aay 2005, 05g00y2b 2005 |

| P/N | 138427-01 (Rev C) |

| Certifications | Ex Na IIC Cl I Div 2 Gp A, B, C, D II 3 G EEx Na [l] IIC T4 LCIE 00 ATEX 6016X Per 139255 II 1/3 G EEx Na [ia] Ia IIC T4 LCIE 00 ATEX 6017X Per 141265 |

| Operating Temperature | -30°C to +70°C |

| Voltage | 24 VDC (Vn = 24VDC) |

| Country of Origin | Made in U.S.A. |

| Weight | 250 gm |

| Reference Number | 62452 |

What is the 1701/15 Proximitor Input Monitor?

The Bently Nevada 1701/15 Proximitor Input Monitor (also known as “FieldMonitor 1701/15”) is a 2-channel monitoring module designed to accept signals from proximity probes (or other compatible transducer I/O), condition those signals into meaningful measurement values, and interface with machinery control or protection systems.

It is part of the larger FieldMonitor family, which offers field-mounted, distributed I/O solutions for condition monitoring and machinery protection — ideal for industrial and marine automation contexts.

Key Features

-

2-Channel Input: It handles two independent input channels, enabling simultaneous monitoring of two sensors (or two points on a machine) via proximity probes or transducer I/O.

-

Measurement Types: The module can measure:

-

Shaft radial vibration (overall vibration)

-

Shaft radial position (gap voltage) — providing relative radial position data.

-

Shaft axial (thrust) position — for thrust bearings or axial displacement monitoring.

-

-

Programmable Alarms: Users can configure alarm setpoints (e.g. Alert / Danger thresholds) for direct (vibration) and gap (position) measurements. The module issues alarm signals to the host control system when thresholds are exceeded.

-

Self-Test / Health Monitoring: The 1701/15 performs embedded self-tests to verify the integrity of both itself and the connected sensors/transducers. If a fault or “NOT OK” condition arises, it can signal the host system.

-

Compatibility & Integration: Designed to integrate with broader FieldMonitor systems and traditional machinery-protection / automation architectures. It supports direct inputs from proximity probes without external conditioning units (depending on configuration), reducing wiring complexity.

-

Compact & Modular: Its modular architecture allows installation close to the monitored machinery (field-mounted), simplifying wiring and making it easier to deploy across distributed systems.

Applications / Use Cases

The 1701/15 Proximitor Monitor is widely used in industrial, marine, and plant environments wherever rotating machinery requires continuous monitoring. Typical applications include:

-

Turbines, compressors, pumps, fans — for real-time monitoring of shaft vibration and position to prevent imbalance, misalignment, or mechanical failure.

-

Energy generation plants — monitoring generators, turbines, and auxiliary rotating equipment to detect early signs of vibration anomalies or bearing wear.

-

Marine / Ship machinery — in engines, shafting systems, and auxiliary machinery where precise vibration and thrust monitoring ensures safety and reliability (a strong match for your marine-automation supply focus).

-

Oil & Gas, Petrochemical, and Process Industries — critical rotating equipment (compressors, pumps, motors) where failure prevention and condition-based maintenance are vital for operational continuity.

-

Manufacturing & Heavy Industry — heavy motors, mills, blowers, or any high-speed rotating equipment needing preventive health checks to avoid downtime.

By integrating 1701/15 into a condition-monitoring regime, plants and vessels can shift from reactive maintenance (fix-after-failure) to predictive maintenance — significantly reducing unexpected shutdowns and maintenance costs.

Why Choose 1701/15 — What Makes It Stand Out

-

Reliable and field-proven: As part of the Bently Nevada FieldMonitor family, 1701/15 comes from a long legacy in machinery-protection instrumentation — trusted in power, marine, and industrial environments worldwide.

-

Flexibility across sensor types: Whether using proximitor sensors, vibration sensors, or accelerometers, it adapts — making it useful in diverse setups.

-

Reduced wiring & installation cost: The field-mounted, distributed I/O architecture simplifies installation and lowers wiring complexity compared with traditional centralized protection racks.

-

Real-time data + alarm + diagnostics: Not only does it monitor vibration/position, but it also provides alarm outputs, integration with control systems, and self-diagnosis — enabling proactive maintenance and safer operations.

-

Compact & modular design for retrofit or new installations: Whether you’re upgrading existing machinery or building new setups (industrial or marine), the 1701/15 offers modularity and ease of integration.