| Attribute | Value |

|---|---|

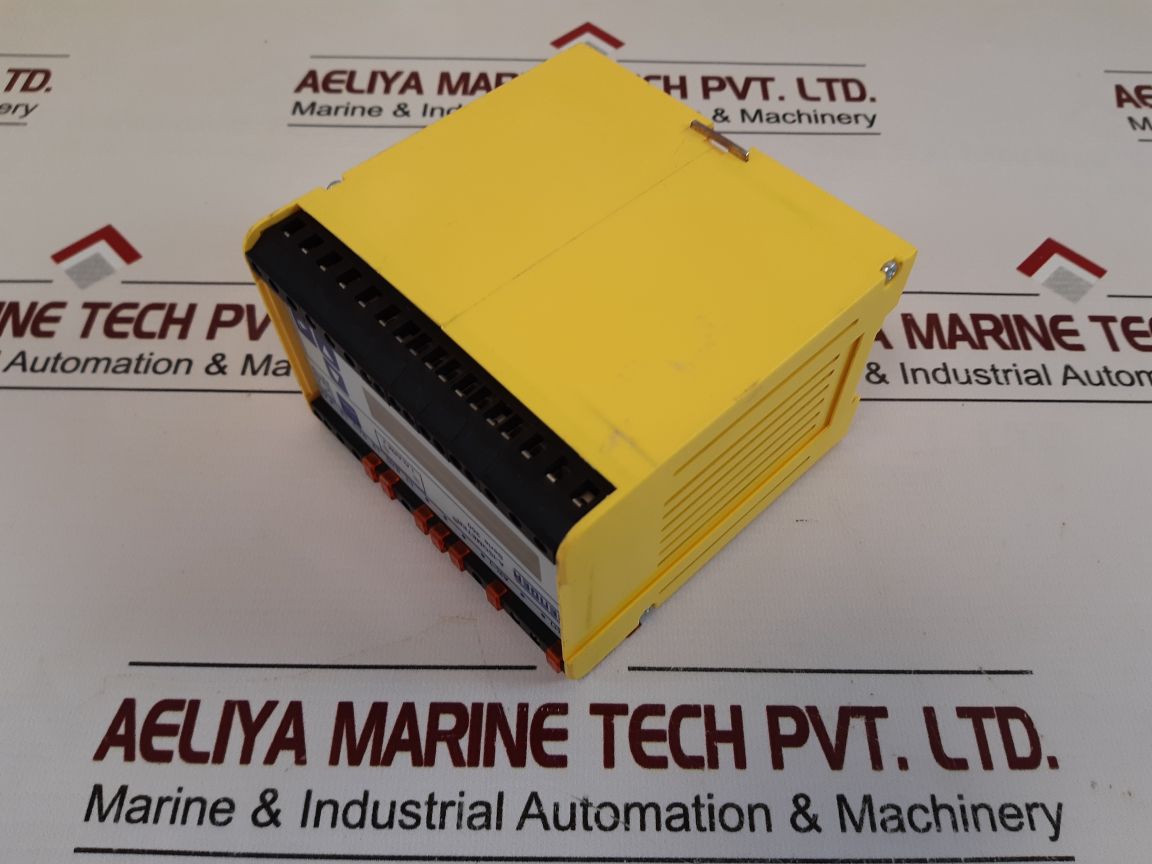

| Product Name | Bender IRDH265-3 Insulation Monitoring Device |

| Brand | Bender GmbH & Co. KG |

| Model / Type | A-ISOMETER, Serie 260, IRDH265-3 |

| Category | KΩ Monitor / Insulation Monitoring Device |

| Software Version | D83 V2.5-3 |

| Article No. | B91068008 |

| Response Value | Ran1 = 2–200 kΩ, Ran2 = 2–200 kΩ |

| Rated Voltage | 3AC/AC 0–440V, DC 0–220V |

| Supply Voltage | AC 230V, 50/60 Hz |

| Power Consumption | 6 VA |

| Relay Contacts | AC 250V, 5A |

| Weight | 750 gm |

| Ref No. | 57277 |

What is a Bender IRDH265-3 Insulation Monitoring Device?

The Bender IRDH 265-3 is an advanced insulation monitoring device used in ungrounded IT power systems. It continuously monitors the insulation resistance between active conductors and earth. The moment the resistance falls to a critical value, the device immediately alarms the operator so prompt corrective measures can be taken.

This device forms part of Bender’s renowned IRDH series of devices, widely used across a number of industries requiring uninterrupted power supply combined with high electrical safety standards. It provides precise monitoring even in complex networks thanks to high-frequency measuring technology and adjustable response values.

Key Features of Bender IRDH265-3

1. Continuous Insulation Monitoring

Continuous insulation resistance monitoring in IT systems

Early detection of insulation faults, preventing breakdowns

2. Adjustable Alarm Thresholds

Set upper and lower resistance limits

Customizable alerts to match system requirements

3. Digital Display for Clear Readouts

Real-time measurement values

Easy monitoring and fault identification

4. High-Frequency Measuring Method

Accurate Detection even in Systems with interference

Reduces false alarms and adapts rapidly to fluctuating network conditions.

5. Compatible with Large and Complex Power Systems

Works well with AC, DC, and mixed networks

Handles variable load systems and frequency converters

6. Relay Outputs for Alarming

Built-in output relays for external buzzers, lights, or PLC alerts

Supports integration with safety automation

7. Self-Monitoring and Diagnostics

Continuously checks its own performance

Ensures reliability and avoids unnoticed device faults.

8. Robust Industrial Design

Long service life

High resistance against electrical noise and harsh environments

Applications

The IRDH265-3 finds a number of applications in electrical devices when continuity and safety are necessary.

1. Marine & Shipboard Systems

- Navigation systems

- Engine control rooms

- Power distribution on vessels

- High humidity and continuous operation call for reliable monitoring in marine applications.

2. Industrial Automation

- Manufacturing plants

- Assembly lines

- CNC machines and robotic systems

- Helps prevent sudden shutdowns due to insulation deterioration.

3. Power Generation & Distribution

- Power stations

- Substations

- IT networks

- Guarantees stable power supply and decreases unplanned failures.

4. Oil & Gas Installations

- Offshore platforms

- petrochemical plants

- Provides reliable monitoring in hazardous zones that require safety-certified equipment.

5. Medical & Hospital Equipment

- Operating theatres

- ICU power supplies

- Prevents electrical failures in life-critical environments.

6. Renewable Energy Systems

- Wind turbines

- Solar farms with inverters

- Monitors insulation to prevent arc faults and damage.

7. Data Centers

- UPS systems

- Server rooms

- Allows for continuous operations and protects sensitive electronics.

Why Choose the Bender IRDH265-3?

✔ Superior Accuracy

Equipped with advanced measuring technology, it provides highly accurate insulation readings even in demanding power systems.

✔ Proven Reliability

Bender is a global market leader in electrical safety solutions. The IRDH265-3 provides trusted performance in marine, industrial, and medical installations worldwide.

✔ Minimizes Downtime

It detects insulation faults early, thus preventing costly shutdowns and equipment failures.

✔ Easy Integration

Compatible with PLCs, alarm panels, automation systems, and safety controllers. The relay outputs allow for easy installation.

✔ Safety Compliance

Helps facilities maintain international electrical safety standards-like IEC and DIN norms.

✔ Long-Term Cost Savings

Early fault detection reduces repair costs, protects equipment, and enhances operational continuity.

✔ Ideal for harsh environments

Designed for stability in environments involving vibration, electrical noise, humidity, or temperature variations.