| Attribute | Value |

|---|---|

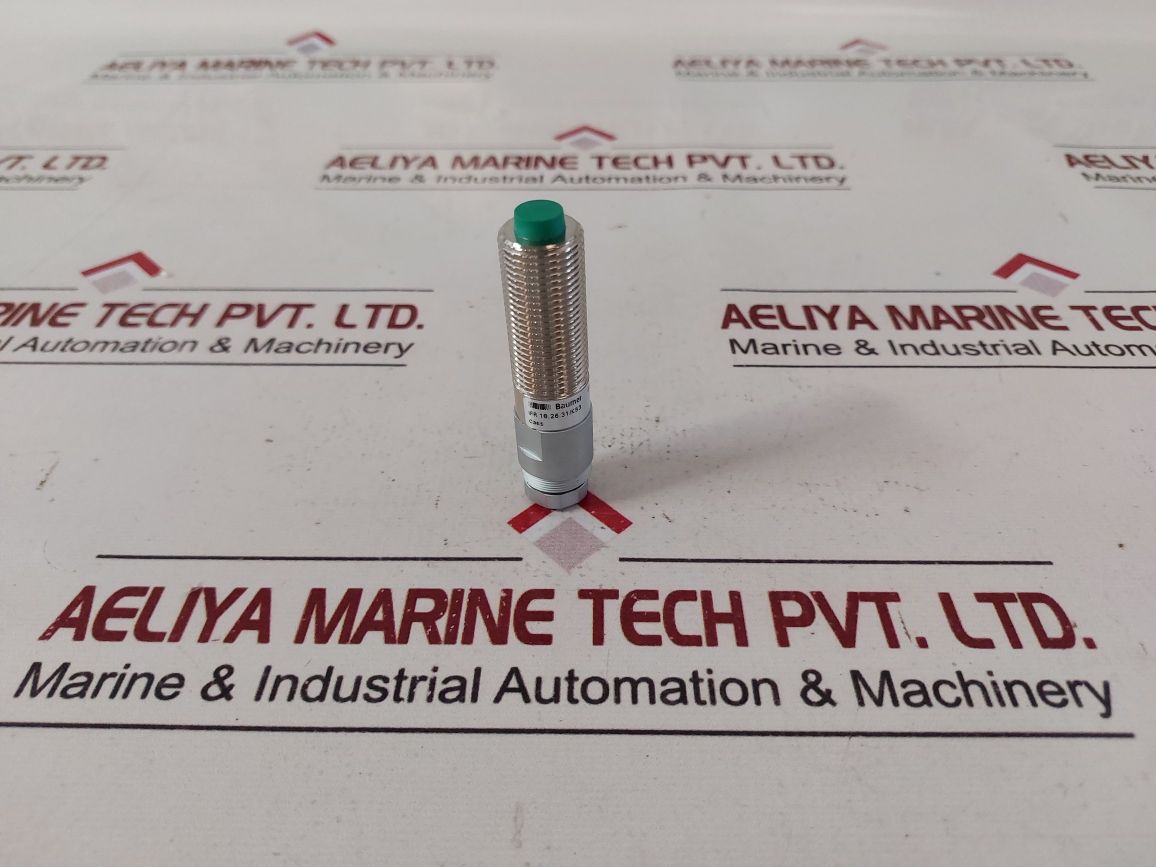

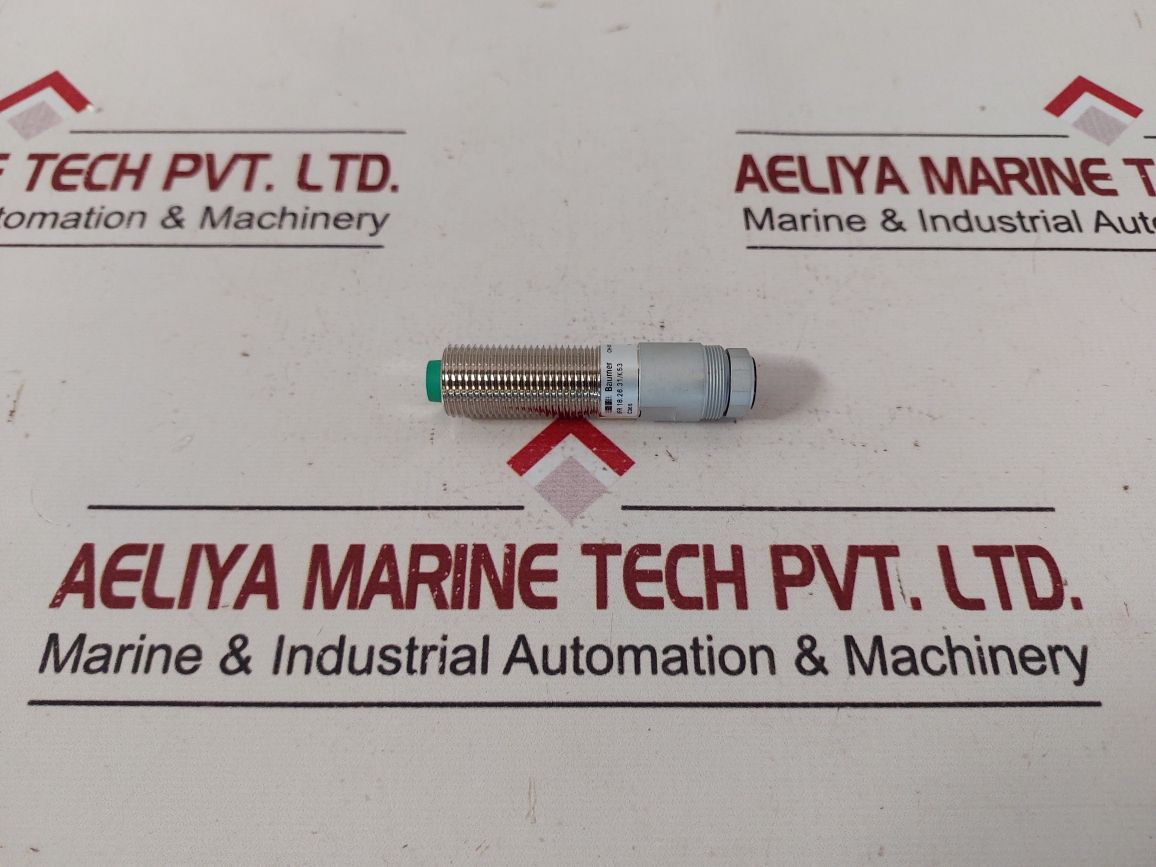

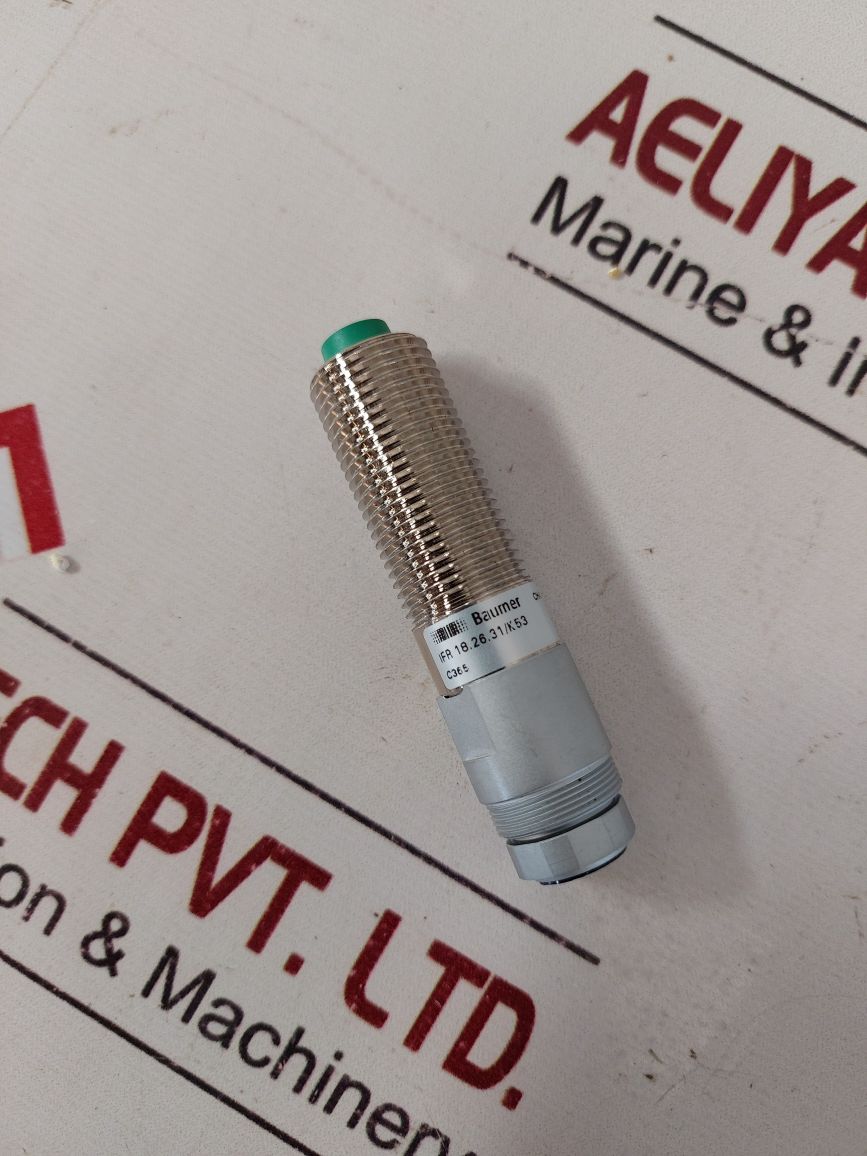

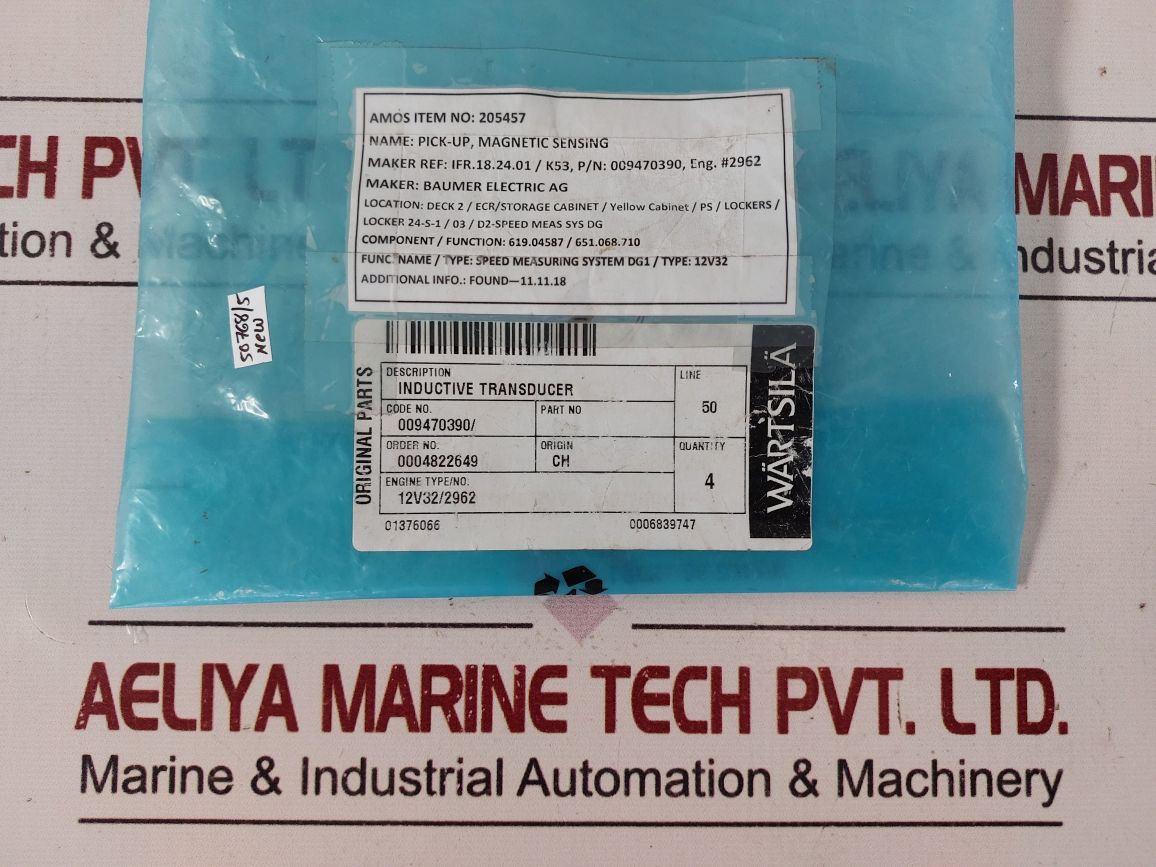

| Item | BAUMER IFR 18.26.31/K53 INDUCTIVE SENSOR |

| Maker | BAUMER ELECTRIC AG |

| Associated Companies | WARTSILA, EUCHNER |

| Model | IFR 18.26.31/K53 |

| Code | C365 |

| Location | CH-8501 |

| Additional Codes | SD4K, BS4K, 002772 |

| AMOS Item No | 205457 |

| Name | PICK-UP, MAGNETIC SENSING |

| Maker Reference | IFR.18.24.01/K53, P/N: 009470390 |

| Component/Function | 619.04587/651.068.710 |

| Function Name/Type | SPEED MEASURING SYSTEM DG1/TYPE: 12V32 |

| Description | INDUCTIVE TRANSDUCER |

| Order No | 0004822649 |

| Codes | 01376066, 0006839747 |

| Manufacture Location | SWISS MADE, MADE IN GERMANY |

| Weight | 150 GM |

| Reference No(s) | 50768 |

What is an Inductive Sensor?

Before discussing the details of the BAUMER IFR 18.26.31/K53, it is necessary to know what an inductive sensor is. An inductive sensor is a type of proximity sensor that detects metallic objects without making any physical contact. They work on the principle of electromagnetic induction, where the coil of the sensor produces an oscillating magnetic field. When a metallic object enters this field, it induces eddy currents in the object, which changes the oscillation characteristics of the sensor, and this is detected by the sensor as a presence signal.

Overview of BAUMER IFR 18.26.31/K53 Inductive Sensor

The BAUMER IFR 18.26.31/K53 is a heavy-duty inductive sensor that can be used with high precision and durability in an industrial environment. The BAUMER Group, one of the well-known companies in automation technology, has engineered this sensor to represent quality and the latest technological advancement in fulfilling the needs of modern automation systems.

Key Features

High Precision Detection: The IFR 18.26.31/K53 sensor has accurate detection of metallic objects, which gives a minimum false trigger and good performance.

Durable Construction: This sensor is built with high-quality materials and is resistant to harsh industrial environments, including dust, moisture, and vibrations.

Adjustable Sensing Range: Users can adjust the sensing distance according to their specific application needs, providing flexibility in various setups.

Fast Response Time: The sensor ensures timely detection with a rapid response mechanism, which is crucial for high-speed automation processes.

Low Power Consumption: It is energy-efficient, with low power consumption without sacrificing performance.

Easy Integration: The sensor can be easily integrated into the standard industrial control systems, allowing it to be seamlessly integrated into the existing setup.

Technical Specifications

Operating Voltage: 10-30V DC, suitable for standard industrial power supplies.

Sensing Range: Adjustable, typically between 5mm to 50mm, depending on the target material and environmental conditions.

Response Time: It has a fast detection time of milliseconds, which means it is real-time responsive.

Housing Material: Stainless steel or other robust materials to be able to withstand industrial environments.

Mounting Options: Variety of mounting options, such as face mount and flange mount, for easy installation.

Connector Type: Standard connectors for simple wiring and connectivity.

Applications of BAUMER IFR 18.26.31/K53 Inductive Sensor

The versatility of the BAUMER IFR 18.26.31/K53 inductive sensor makes it suitable for a wide range of applications across various industries:

1. Manufacturing Automation

In manufacturing lines, the sensor can identify the presence of metallic parts, thereby allowing accurate placement and movement of parts. This is important for assembly lines, packaging, and material handling systems.

2. Conveyor Systems

The IFR 18.26.31/K53 installed on conveyor belts can monitor the movement of goods, identify jams, and manage the flow of materials efficiently to minimize downtime and maximize productivity.

3. Robotics

In robotic applications, the ability to detect objects correctly is necessary for picking, placing, and assembly functions. It provides feedback to the control unit of the robot so accurate movements and operations can be performed.

4. Automotive

From the assembly lines up to the quality control, the inductive sensor ensures metal parts are correctly counted and placed for proper accounting in high production standards.

5. Packaging Machines

In packaging, the presence and position of containers or packages are detected to ensure that filling, sealing, and labeling processes are not made with errors, thereby increasing the efficiency of the packaging line.

6. HVAC Systems

Sensors such as the IFR 18.26.31/K53 can monitor the presence of metallic components in heating, ventilation, and air conditioning systems, ensuring optimal performance and maintenance.

Advantages of BAUMER IFR 18.26.31/K53 Inductive Sensor

The following are the advantages that come with using the BAUMER IFR 18.26.31/K53 inductive sensor:

Reliability

Baumer sensors guarantee reliability and have a long lifetime. The IFR 18.26.31/K53 is designed for reliable operation, even in unfavorable conditions, resulting in fewer frequent replacements and minimal maintenance.

Accuracy

The inductive sensor allows for high-accuracy detection of objects, making it possible for automation systems to operate with precision and efficiency in the detection processes.

Flexibility

The adjustable sensing range and mounting options make it versatile for multiple applications and setup configurations, making it flexible to engineers and technicians.

Energy Efficiency

Low power consumption contributes to overall energy savings, making it an environmentally friendly choice for industrial automation.

Easy Integration

It is compatible with standard control systems, which allows the sensor to be easily integrated into existing infrastructures, thus saving time and reducing complexity.