| Attribute | Value |

|---|---|

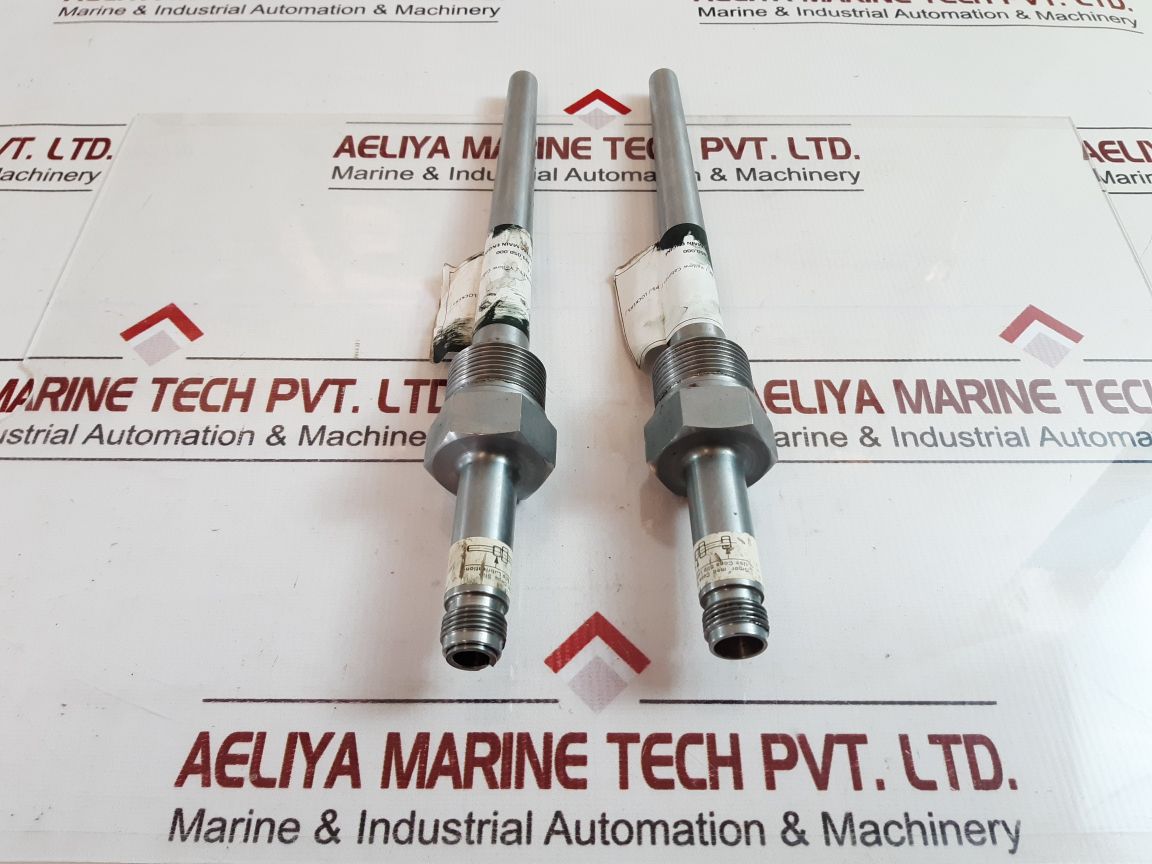

| Product Name | AUTRONICA MB236-200 |

| AMOS Item No | 214622 |

| Name | PROTECTION, WELLME |

| Maker Ref | MB236-200 |

| Maker | AUTRONICA A.S. |

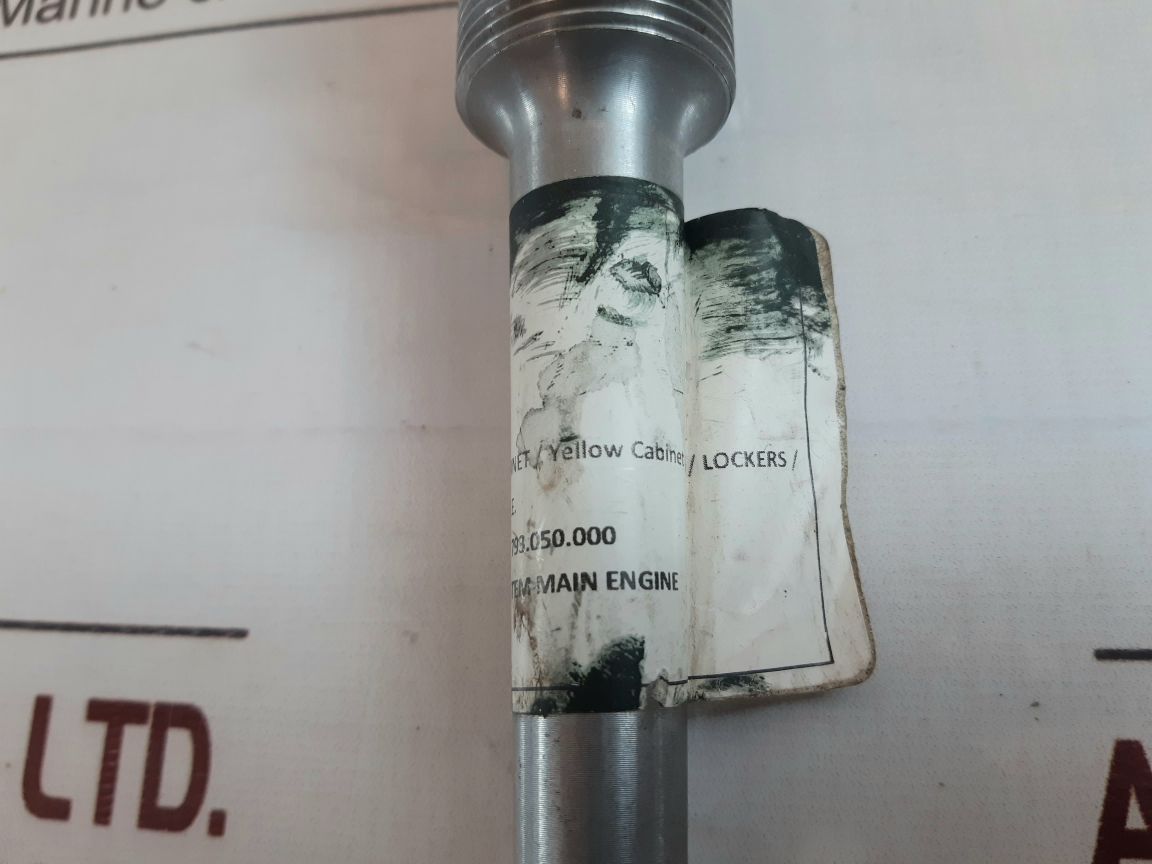

| Component / Function | 619.05966 / 793.050.00 |

| Function Name / Type | Automation System Main Engine |

| Weight | 580 GM |

| Condition | Used (2 PCS) |

| Reference No | 45811 |

What is Autronica MB236-200 Protection Well

The Autronica MB236-200 protection well is a protective sensor housing or sheath that can shield temperature sensors (thermocouples or RTDs) against hostile environments, including exhaust gas lines or high-temperature fluid streams in ship and plant systems. It acts as a cover between the sensor and the process medium that enables the sensor to measure temperature without exposure to corrosive, abrasive, or high-velocity conditions.

In engine and marine systems, exhaust gas lines become extremely hot and can consist of gases, soot, or corrosion byproducts. The MB236-200 well is capable of withstanding those conditions, shielding the sensor element and prolonging its life.

In Kongsberg’s documentation, the MB236 series is intended for protection in exhaust gas use, constructed of high-temperature chromium steel, 200 mm in length.

Kongsberg

Typical specifications:

Material: high temperature chromium steel (appropriate for prolonged higher temperatures)

Length: 200 mm (reflecting the MB236-200 model)

In order to protect temperature sensors in exhaust gas / high temperature applications

Weight in the range of ~535 g (for the 200 mm model)

As such, MB236-200 is one of a family of protection wells (e.g. MB235, MB237) designed for the same use cases.

Key Features

Here are the key characteristics of the MB236-200 and what to emphasize:

Construction with high-temperature material: Constructed from chromium steel that is capable of withstanding high temperatures common in exhaust gas pipes.

Uniform length: 200 mm length configuration offers adequate depth of insertion for most exhaust or duct systems.

Kongsberg

Thread or flange arrangements: Adjustable connection threads or mounting for use in piping or exhaust assembly integration (based on variant).

Mechanical strength: Built to withstand vibrational, thermal cycling, and stress environments typical in marine engine applications.

Corrosion & oxidation resistance: The specified chromium steel is intended to withstand oxidation and corrosive gases found in exhaust engine gases.

Sensor compatibility: Designed to accommodate standard sensor diameters (thermocouple, RTD) so that the sensor cartridge can insert or be mounted within.

Maintenance / replacement ease: Since the sensor is located inside the well, you may be able to replace the sensor without taking the well out.

Thermal lag consideration: The well does introduce some thermal lag between the sensor and process, but this is deemed acceptable considering the protection advantages.

Standardization in marine applications: Since MB-series wells are deployed in marine instrumentation, it is easier to locate matching sensors or spares.

You can also specify tolerances, thermal expansion design, or industry certification if you have that information from the manufacturer or datasheet (you might want to include a datasheet PDF as a download link in the blog).

Applications

Where and how the MB236-200 protection well is applied:

Marine engine exhaust systems: The exhaust gas temperature (EGT) sensor in ship engines is essential for performance measurement, emissions, and safety. Well shields the sensor from direct flame, soot, and corrosive exhaust gases.

Power generator exhaust lines: Land or sea power generators also require protection in exhaust measurement.

Industrial combustion systems: Boilers, furnaces, or gas turbines where you want to measure gas temperature in aggressive combustion streams.

Process gas lines: In petrochemical or chemical plants with high-temperature gas lines where protection of sensors is critical.

Heat recovery systems: In waste heat recovery, the well protects longevity of sensors that are installed in hot ducts or flues.

Retrofit & replacement in existing systems: If an existing old well or sensor housing becomes compromised, MB236-200 is an effective replacement in most installations.

Why Select MB236-200 / Benefits

Here you convince your customers why they should use this product:

Strength and dependability

Its heavy chromium-steel design survives high temperature, corrosion, and mechanical stress, minimizing downtime and maintenance intervals.

Increased sensor life

By protecting the sensor from direct contact with combustion gases, soot, and particulate matter, the well extends the sensor’s life.

Maintenance ease / replacement of the sensor

You can replace or remove the sensor cartridge without disrupting the entire piping or manifold installation.

Compatibility & standardization

The MB series (MB235, MB236, MB237) is typical of marine instrumentation, so spares and matching sensors are simpler.

Long-term cost saving

Fewer failures and downtime equate to reduced total cost of ownership in hostile environments.

Installation flexibility

The default 200 mm length usually covers most exhaust duct configurations, while you can opt for thread/flange versions to fit your system.

Reliable in marine & industrial applications

Since wells of this type are designed to withstand hostile environments, users in marine, power, and process industries rely on the MB236 line.

Improved system protection / safety

Protecting sensors ensures your monitoring and control systems maintain integrity, avoiding false readings or sensor burnout.