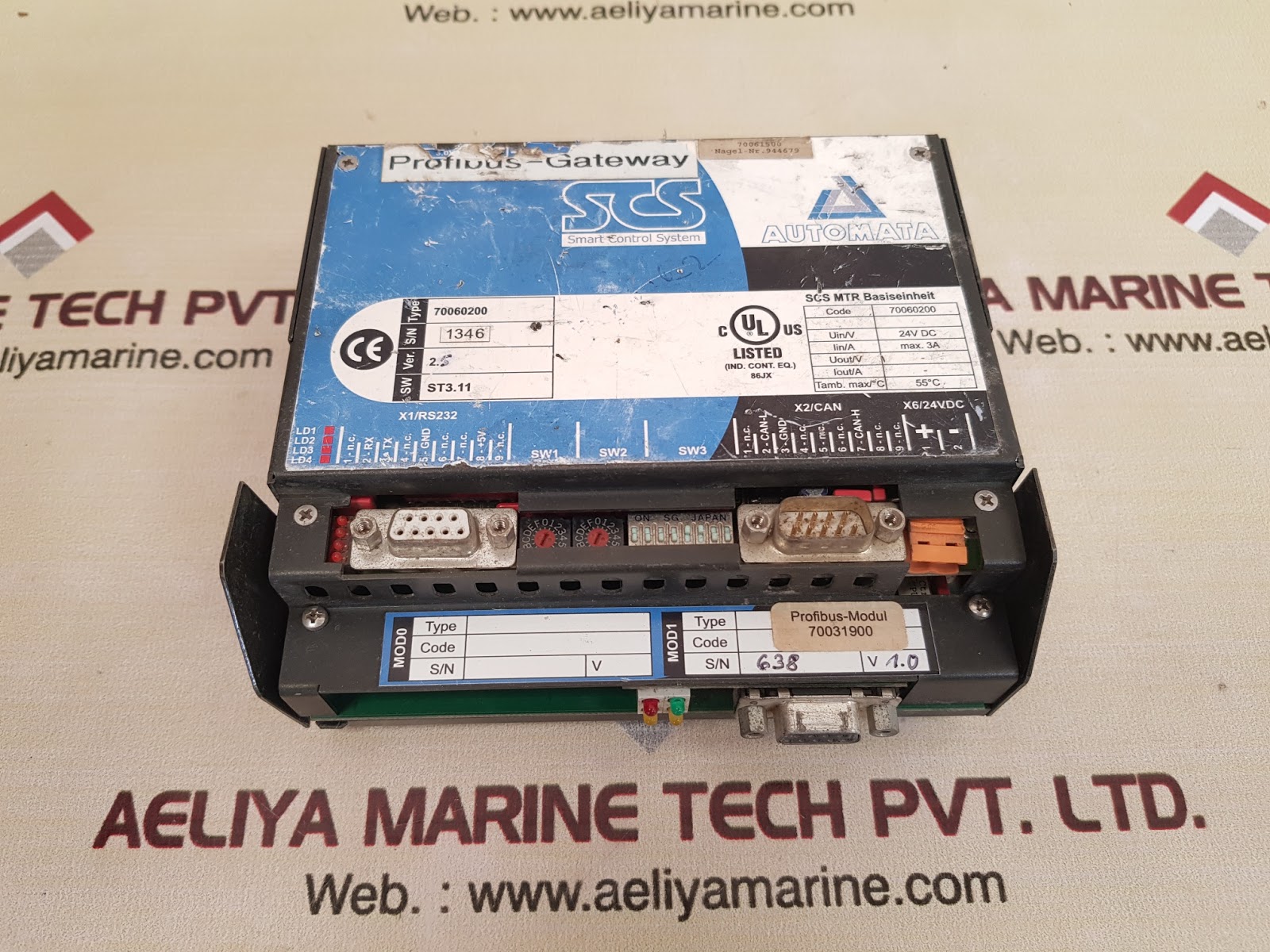

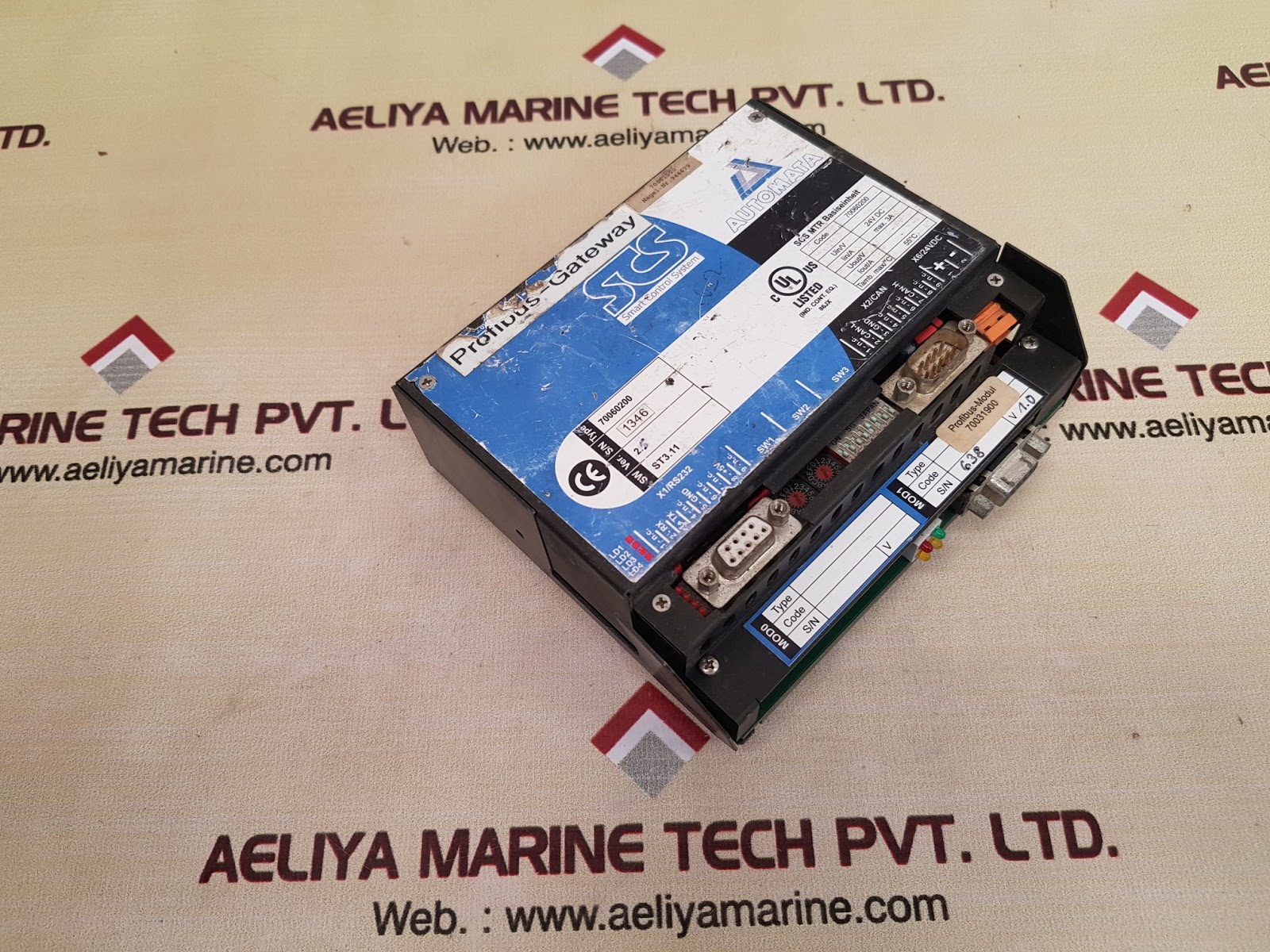

| Attribute | Value |

|---|---|

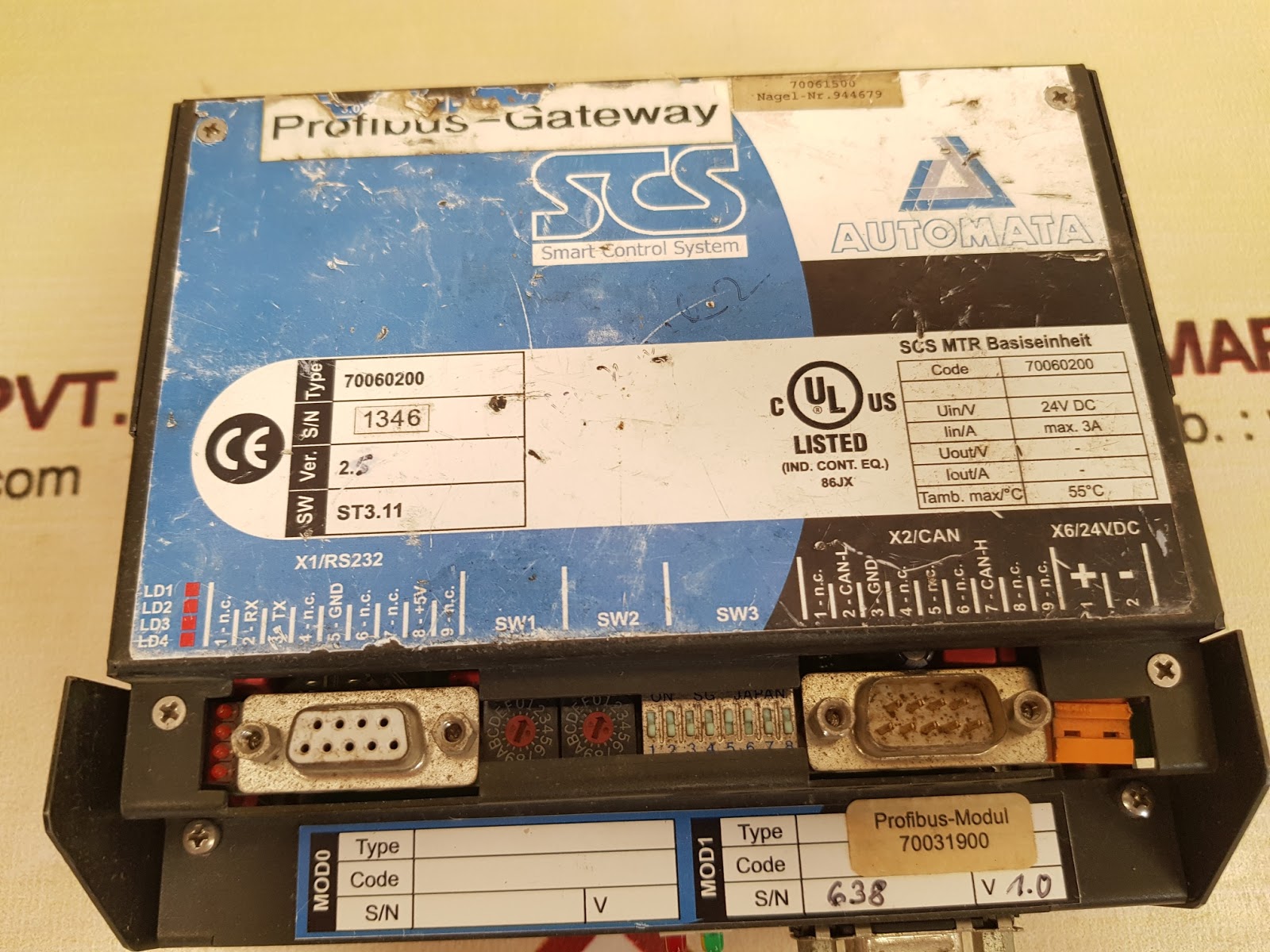

| Product Name | Automata 70060200 Smart Control System |

| Category | Smart Control System |

| Abbreviations | SCS, Automata |

| Gateway Type | Profibus-Gateway |

| Alternate Code | 70061500 |

| Nagel Number / Nail No. | 944679 |

| Base Unit Description | SCS MTR Basiseinheit / SCS MTR Base Unit |

| Type/Code | 70060200 |

| Version | 2.5 |

| Software Version | SW ST3.11 |

| Input Voltage | 24V DC |

| Current (Max) | 3A |

| Max Operating Temperature | 55°C |

| Profibus Module | 70031900 |

| Profibus Version | 1.0 |

| Country of Manufacture | Japan |

| Weight | 775 gm |

What is the Automata 70060200 Smart Control System?

The Automata 70060200 is a state-of-the-art smart control unit engineered for industrial applications. Whether you’re managing a manufacturing line, packaging unit, or processing plant, this compact yet robust controller delivers advanced automation capabilities in a user-friendly package.

It integrates hardware and software functionalities to provide real-time monitoring, feedback loops, data logging, and seamless communication with other automation equipment.

Key Features

High-Speed Processing

With a robust microcontroller, the 70060200 processes control logic and commands in real time, minimizing delays and system responsiveness.

Flexible I/O Configuration

The intelligent control system accommodates several digital and analog input/output (I/O) points for straightforward integration with sensors, actuators, and other field devices.

Ethernet and Serial Communication

With built-in Ethernet, RS-232, and RS-485 ports, it allows seamless data transfer with HMIs, PLCs, and SCADA systems over different protocols.

Intuitive User Interface

Users can set up and track processes via an easy, menu-based interface, minimizing setup time and making trouble shooting easier.

Modular and Expandable Design

Suitable for small-scale use as well as for large industrial applications. Allows expansion through add-on modules, providing future-proof expandability.

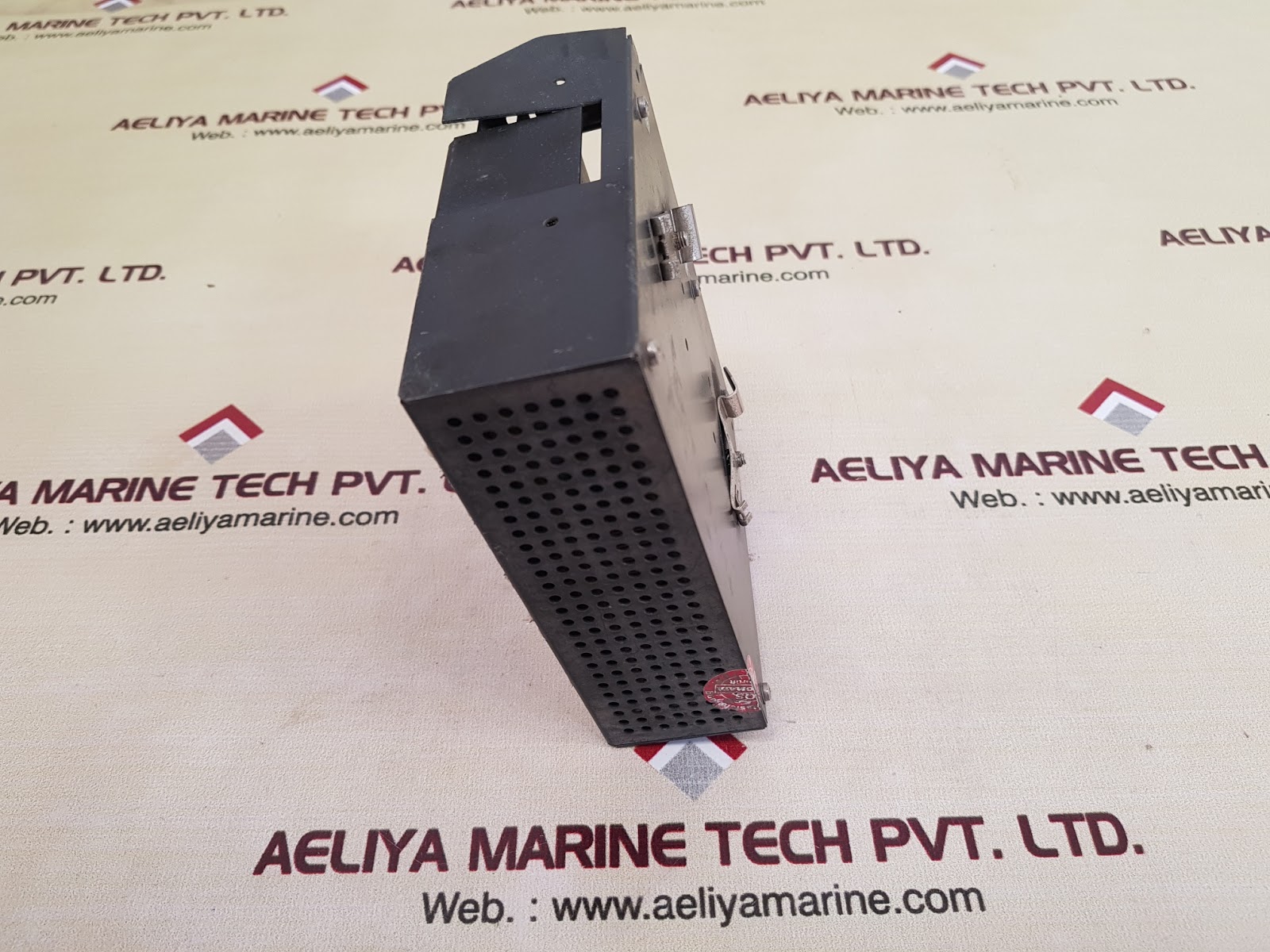

Rugged Design

Enclosed in an industrial-grade cabinet, the system is dust-resistant, vibration-proof, and temperature-resistant—ideal for use in harsh environments.

Applications

The Automata 70060200 is applied to various industries:

Manufacturing: Operates conveyor belts, robotic arms, and automated assembly lines.

Food & Beverage: Controls temperature, mixing cycles, and quality control checks.

Energy Management: Controls load distribution, measures power factors, and switches on automatically.

Water Treatment Plants: Automates with accuracy pumping, filtering, and dosing of chemicals.

Packaging Units: Coordinates synchronized movement of products at wrapping, sealing, and labeling phases.

One of the best features is that it can talk to several systems at once—developing a centralized control center that makes management easier and reduces mistakes.

Benefits

Enhanced Operational Effectiveness: Repetitive and complicated task automation saves time and manpower.

Cost Reduction: Through reduced downtime and minimized human error, facilities minimize maintenance and operating costs.

More Accurate: Sensor feedback and data logging ensure accurate control and quality control.

Remote Monitoring: IoT compatibility and cloud support enable operators to monitor systems almost anywhere.