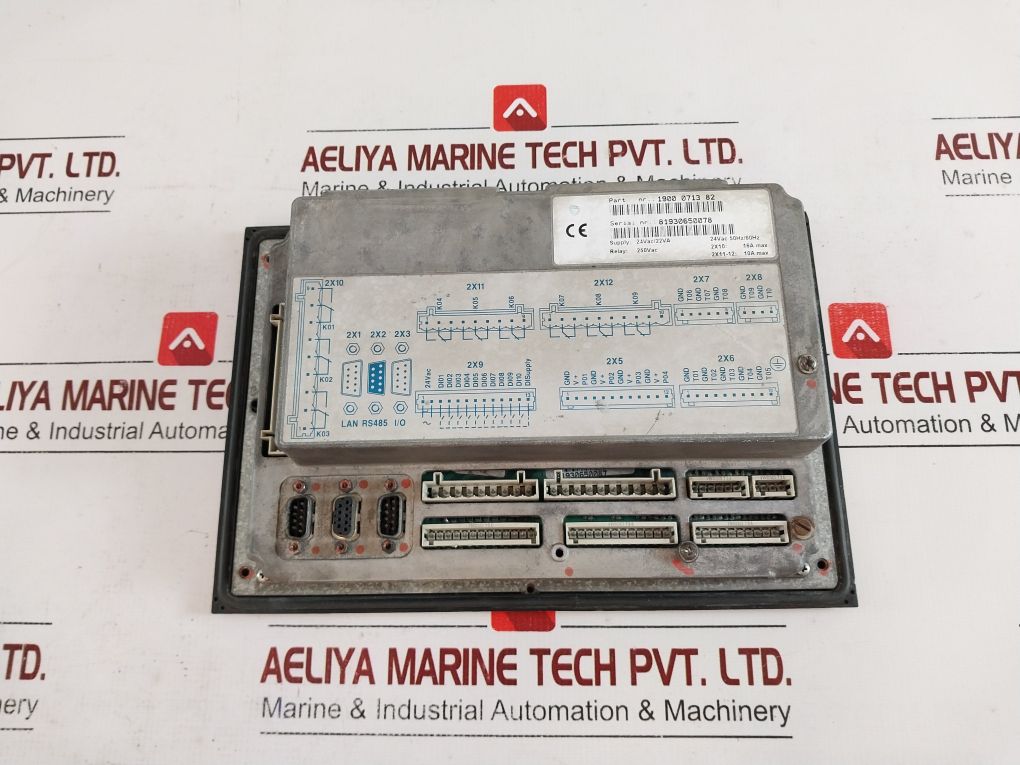

| Attribute | Value |

|---|---|

| Product | Atlas Copco 1900 0713 82 Compressor Controller Panel |

| Brand | CP – Chicago Pneumatic / Atlas Copco |

| Part Number | 1900 0713 82 |

| Supply | 24 VAC / 22 VA |

| Relay Rating | 250 VAC |

| Frequency | 24 VAC 50/60 Hz |

| Output Ratings | 2×10: 16A Max 2×11-12: 10A Max |

| Weight | 1.540 Kg |

| Ref No | 63176 |

What is the Atlas Copco 1900-0713-82 Compressor Controller Panel?

The Atlas Copco 1900 0713 82 is an advanced compressor controller panel engineered to manage and optimize the operation of Atlas Copco air compressors. It acts as the central control hub that monitors system conditions, regulates compressor behavior, and ensures safe, stable, and energy-efficient performance.

This controller panel combines in one package functions such as electronic control, real-time monitoring, safety interlocks, system diagnostics, and user interface. Installed in either industrial plants or marine systems, it allows operators to maintain consistent output of compressed air while minimizing operational downtime.

Key Features of the Atlas Copco 1900 0713 82 Controller Panel

1. Smart Compressor Management

This panel automatically controls load/unload cycles, pressure levels, and compressor start/stop sequences for effective air delivery.

2. Real-Time System Monitoring

It continuously tracks parameters such as pressure, temperature, motor load, run hours, and fault conditions to maintain system stability.

3. Advanced Safety Protections

The built-in safety systems guard the compressor against:

- Overpressure

- Overheating

- Motor overload

- Electrical faults

- Low oil or lubrication failure

These safeguards help prevent costly breakdowns and also extend equipment life.

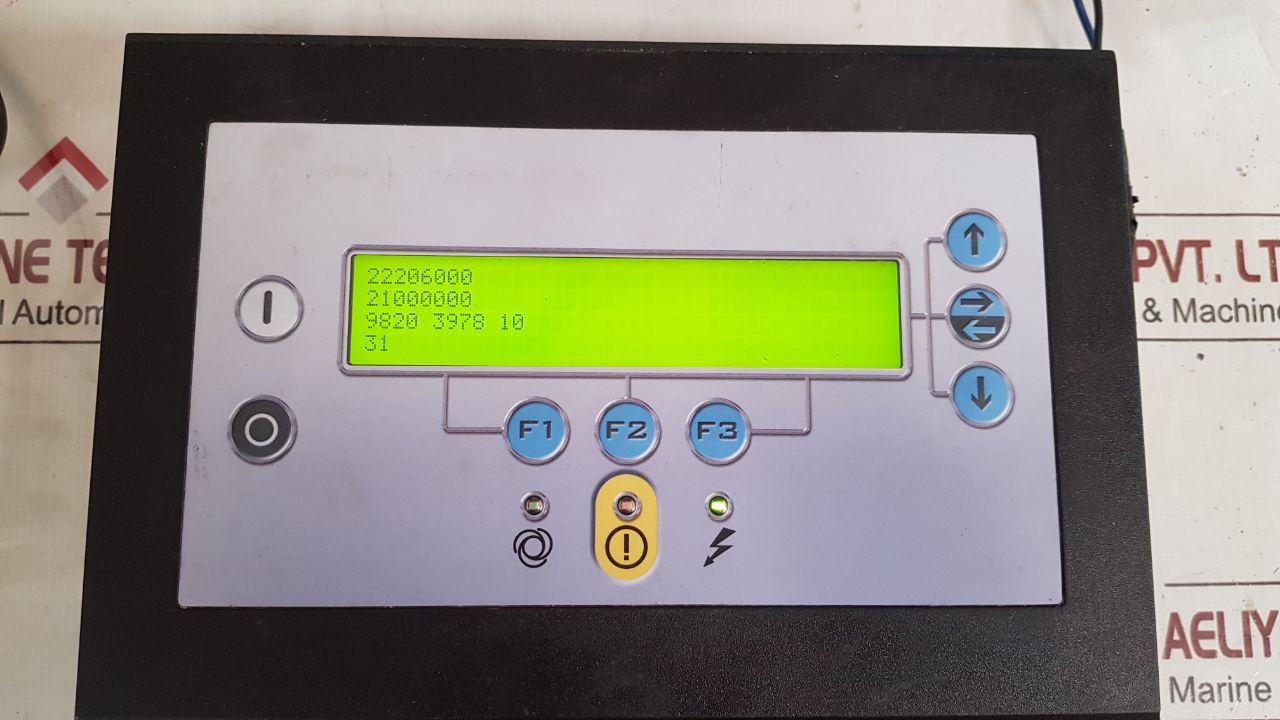

4. User-Friendly Interface

Equipped with a clear display, intuitive navigation enables operators to easily adjust settings, access logs, or troubleshoot alerts.

5. Diagnostic and Alarm Functions

The panel gives detailed fault codes and historical data for quick identification of issues; hence, there is reduced time for maintenance.

6. Heavy-Duty Industrial Construction

It is designed to withstand industrial heat, vibration, and harsh environments, hence suitable for offshore, marine, and heavy-duty applications.

7. Energy Efficiency Optimization

The controller thereby aids in the reduction of electricity consumption through intelligent power management, thus significantly reducing operation costs.

8. Compatibility with Atlas Copco Compressors

Designdevelopment is exactly for the Atlas Copco systems to make sure they fit perfectly and work stably over a long period of time.

Applications of the Atlas Copco 1900 0713 82 Controller Panel

The controller panel finds broad applications across industries depending on reliable compressed air supply, including:

1. Manufacturing Plants

Applied in automatic machines, pneumatic tools, packaging, and assembly lines, where a continuous flow of air is needed.

2. Marine & Offshore Vessels

Supports on-board equipment, air start systems, deck machinery, and control operations, both on ships and offshore rigs.

3. The Oil & Gas Industry

Ideal for rigs, refineries, and other processing plants needing hardy explosion-proof compressor management systems.

4. Power Generation Units

Ensures dependable air supply for turbine cleaning, cooling systems, and pneumatic actuators.

5. Automotive & Aerospace Industries

Used in painting booths, testing equipment, CNC machines, and component manufacturing.

6. Food & Beverage Processing

Supports compressed air systems for hygiene applications in filling, packaging, and production equipment.

7. Chemical & Pharmaceutical Industries

Ensures system stability for sensitive production processes-even small changes in the air can affect product quality.

Why Choose the Compressor Controller Panel Atlas Copco 1900 0713 82?

1. Proven Reliability

Atlas Copco is a globally trusted brand known to build quality industrial control solutions. This panel ensures stable compressor performance without any interruptions.

2. Operational Safety Enhanced

With multi-level protections, faults are detected early, preventing severe equipment damage and reducing downtime.

3. Reduced Maintenance Efforts

Diagnostics features allow for quicker troubleshooting, thus helping the technician manage repairs efficiently.

4. Energy Savings

Optimized compressor cycles and smart control functions considerably reduce energy consumption.

5. Long Service Life

The controller panel is built with rugged components that are performing exceptionally in demanding industrial and marine environments.

6. Easy Integration & Replacement

Also suitable for new installations, as well as replacing in already existing Atlas Copco systems: guarantees minimal setup time.

7. Improved Productivity

Stable air output, precise control, and continuous monitoring enable industries to continue operating uninterruptedly, thus increasing efficiency.