| Parameter | Details |

|---|---|

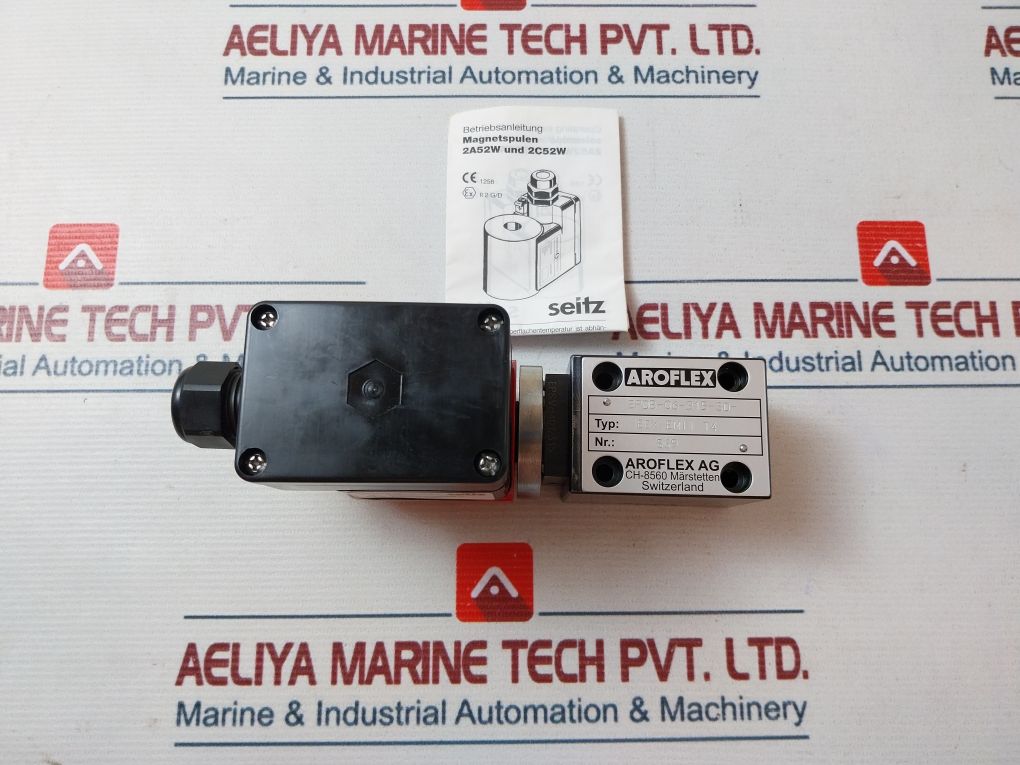

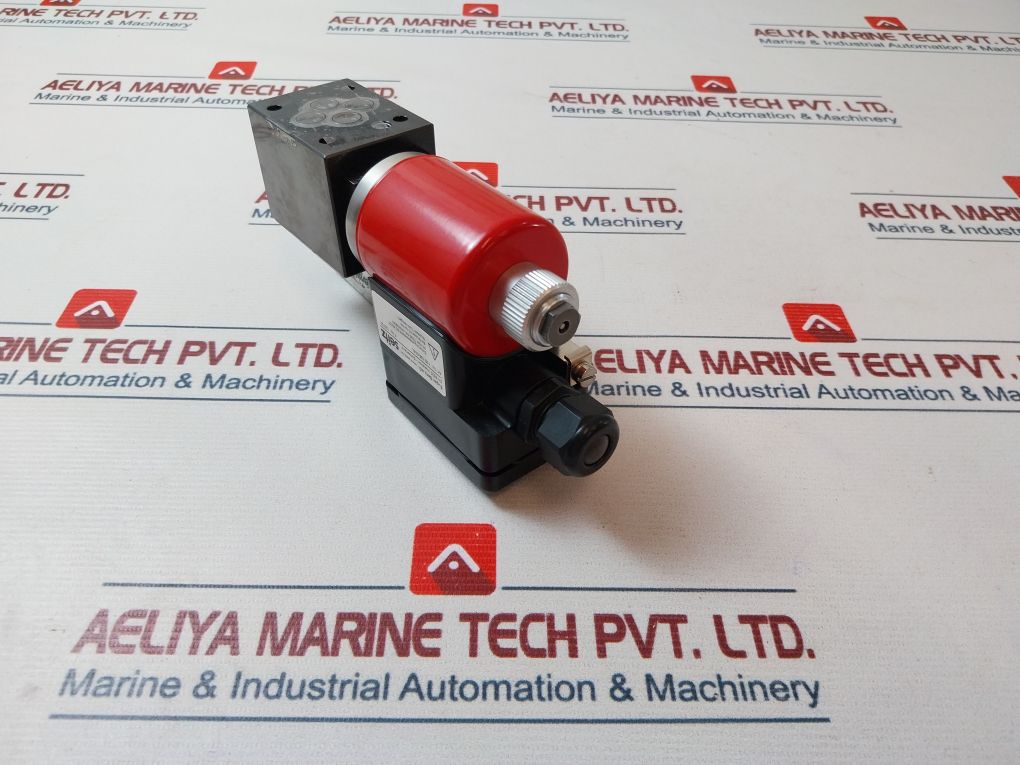

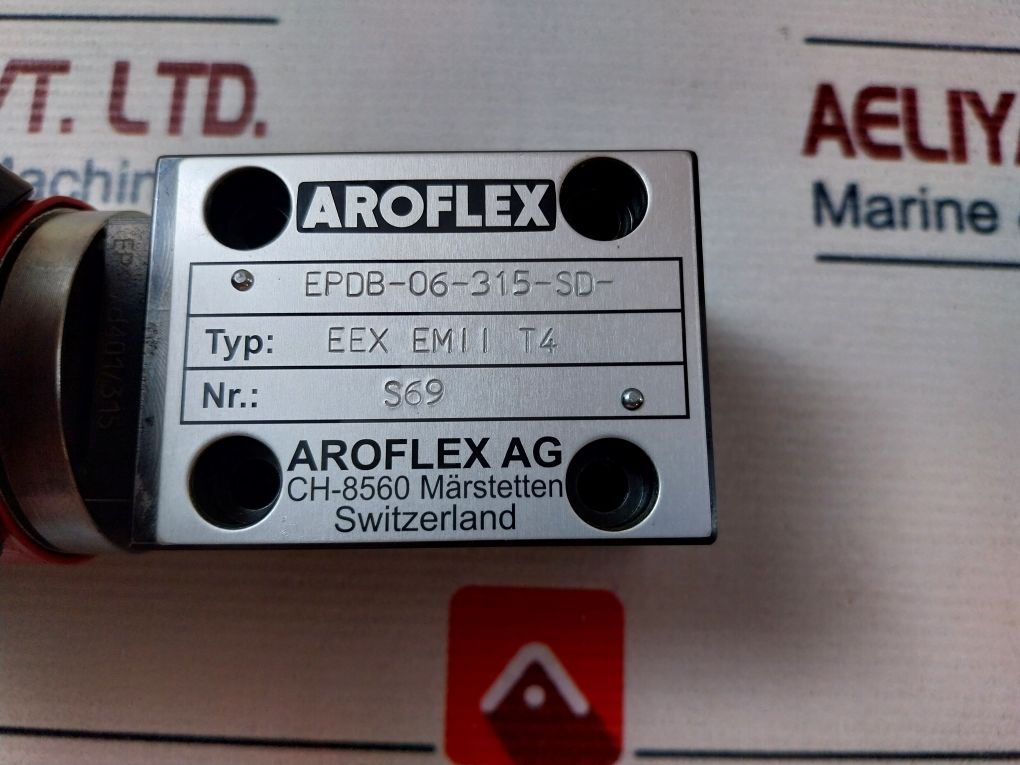

| Product Name | Aroflex EPDB-06-315-SD Pressure Relief Valve EEx EmII T4 |

| Manufacturer | Aroflex AG |

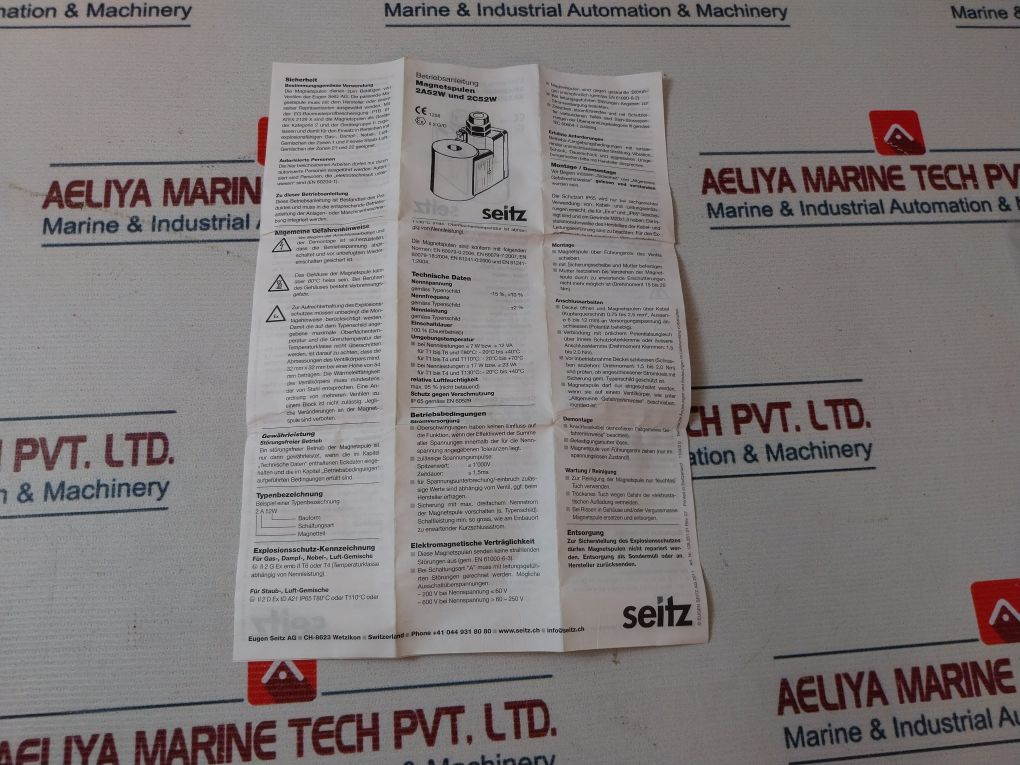

| Additional Manufacturer | Eugen Seitz AG |

| Type | EEx EmII T4 |

| Model Number | EPDB-06-315-SD |

| Reference Number | S69 |

| Product Number | EPSVD401/315 |

| Article Number | 118.195.024L |

| F.No | 120727 |

| Type Code | 2A52W |

| Voltage | 24 V DC |

| Ingress Protection | IP65/67 |

| Power Consumption | 17 W |

| PTB Number | Ex-01 IEC 2132 X |

| Ex Protection | Ex Em II T4 |

| ATEX Number | PTB 01 ATEX 2129 X |

| Explosion Protection | II 2 G Ex Emb II T4 |

| Dust Protection | II 2 D Ex Td A21 IP65 T130°C |

| Serial Number | 129109834 |

| Country of Manufacture | Swiss Made |

| Weight | 1.980 Kg |

| Reference Number | 78242 |

Key Features of the Aroflex EPDB-06-315-SD Magnetic Coil

The Aroflex EPDB-06-315-SD coil is designed to perform perfectly and safely. In fact, this version falls in the category of EEx emII T4 in Europe, and their classification means they are dangerous for use in explosive environments. Here are some of its key features:

Explosion-Proof Design: The EEx emII T4 rating means that this coil is safe to operate in an explosive gas environment. The “EEx” stands for compliance with the European safety standards about the explosive atmospheres, and “mII” is encapsulation for more safety and thus is appropriate for use in environments of combustible gases and vapors.

Temperature Tolerance: The T4 temperature grading means the coil can have the surface at maximum temperature of 135°C or 275°F. This means it will have an opportunity to be used in most industrial applications to ensure that such a component performs uniformly in high heat conditions, which is an inherent characteristic for components exposed to various conditions.

Reliability in Operation : EPDB-06-315-SD has guaranteed stable operation for a long time, as the manufacturing of the device was based on stability and sustainability. With such demands the equipment won’t show any decrement of performance so no frequent replacements which would help in low costs of maintenance.

Technical Specifications

The full capability can only be understood when looking at the specifications of Aroflex EPDB-06-315-SD.

Model: EPDB-06-315-SD

Product Type: Magnetic Coil

Grade: EEx emII T4

Max Temp: Up to 135°C (T4)

Application: Hazardous industrial environments such as oil and gas and chemical processing

Durability: High strength designed for extended industrial use

The specifications will make the Aroflex EPDB-06-315-SD fit quite well in high-demand industrial applications so the industries that require security and reliability can assured of utilizing the product.

Applications of the Aroflex EPDB-06-315-SD Magnetic Coil

Due to its classification under EEx emII T4, this coil finds wide usage in the various industries that face explosive and hazardous situations. Some of the most common applications include the following.

Oil and Gas Industry: The coil is mostly installed in drilling rigs and refineries where there are flammable gases so that proper safety and regulation in industries are maintained.

Chemical Processing: Process plants working with flammable products use only EEx-rated apparatus to stay safe, and therefore, a magnetic coil need can easily be met with the Aroflex EPDB-06-315-SD.

Pharmaceutical Manufacturing: When combustible dusts are involved, pharmaceutical companies utilize explosion-proof parts to ensure a safe working environment.

Mining: Underground mining operations frequently encounter combustible gases and the explosion-proof coils assure safety of personnel and equipment in such extreme conditions.

Why Aroflex EPDB-06-315-SD?

The advanced safety feature EPDB-06-315-SD coming from this can really make huge gains for the industries working in hazardous conditions. Its robust construction with the EEx emII T4 certification makes it definitely a reliable component while the safety cannot be compromised in such environments. Thus, businesses can rely on safe and reliable products with Aroflex’s magnetic coil while the risks of malfunctioning or non-compliance issues with required regulations can’t come in its way at work.

Reviews

There are no reviews yet.