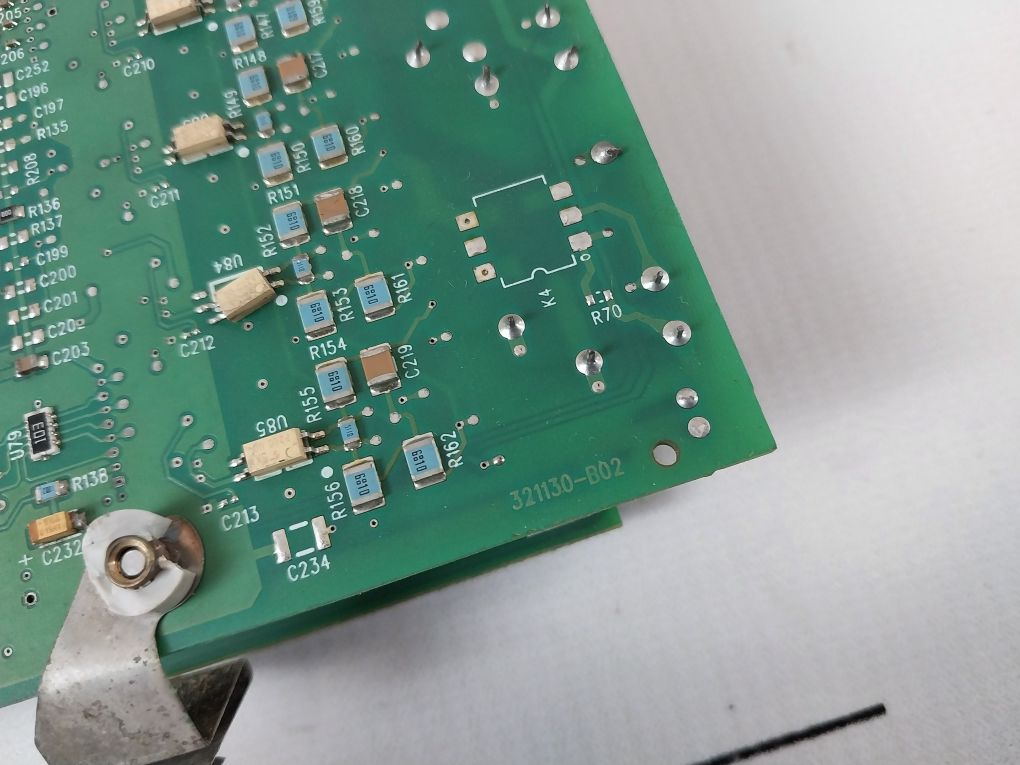

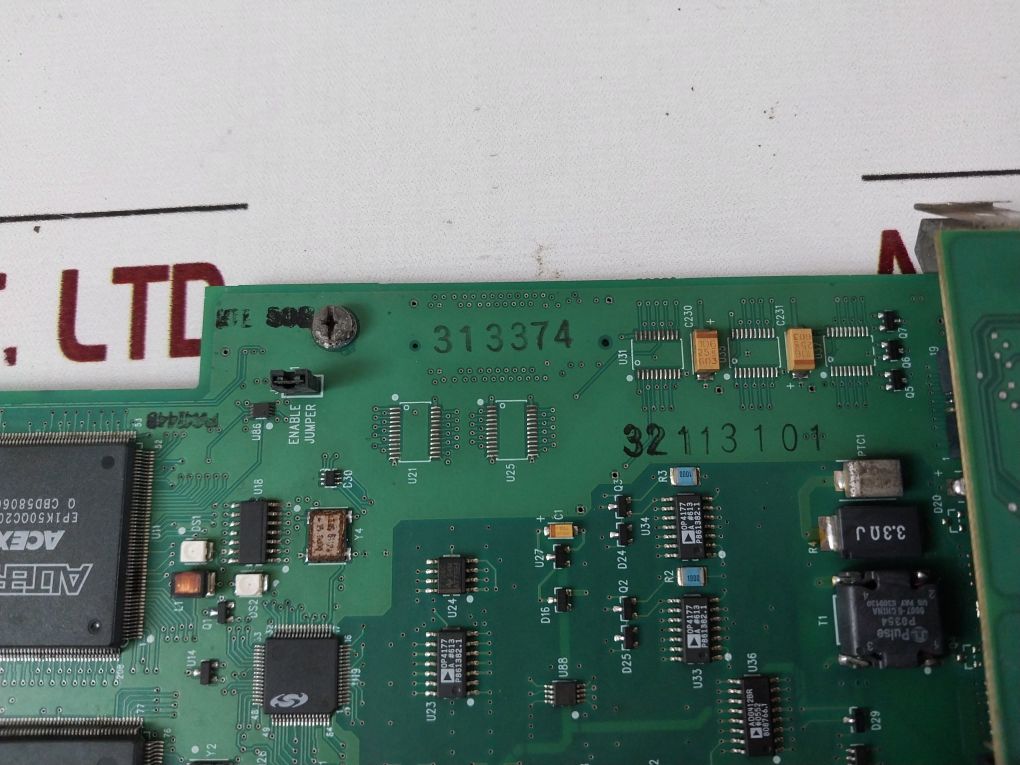

| Attribute | Value |

|---|---|

| Product Name | Allen-Bradley Rockwell Automation 321131-A01 Inverter Control Board |

| Brand | Allen-Bradley / Rockwell Automation |

| Model Numbers | 321130-B02, 354781-B02, CEC3-0, 05-40, 321131-A01, REV 06, 2606, 349121-A01, V.4.005 |

| Weight | 220 gm |

| Ref No(s) | 63349 |

What is an Allen-Bradley 321131-A01 Inverter Control Board?

The 321131-A01 Inverter Control Board is an application-specific board utilized within the Allen-Bradley drive system. It serves as the logic and signal-processing hub of an inverter to effect the variable speed, torque, and other functional controls of AC motors.

This is a module on the PCB managing input signals, coordinating power electronics, performing diagnostic checks, and communicating with the broader automation system. Being an integral part of the drive’s internal architecture, it helps in smooth motor operation and protection against overloads, voltage fluctuations, and other failure conditions.

Key Features

1. Advanced Signal Processing

It interprets the commands from PLCs, sensors, and operator interfaces and translates them into motor control signals in a way that assures stability and efficiency.

2. Robust Rockwell Automation Design

Constructed to the Allen-Bradley standard for quality, it provides years of operational life, reliability, and is compatible with several inverter series from Rockwell.

3. Protection and Diagnostics Fully Integrated

Includes protection mechanisms for:

- Overvoltage

- Overcurrent

- Overheating

- Phase imbalance

- Diagnostic LEDs and circuitry enable the technician to rapidly identify and troubleshoot problems.

4. High-Quality PCB Construction

The board is manufactured with industrial-grade components to ensure:

- Heat resistance

- Vibration tolerance

- Stable performance in extreme environmental conditions

5. Effortless Communication Capabilities

Designed to support communication with other automation components, such as:

- PLC systems

- Human Machine Interfaces (HMIs)

- Industrial networks

6. Easy Replacement & Maintenance

Its modular design features standardized connectors, allowing quick replacement without significant system downtime.

Applications

The Allen Bradley 321131-A01 Inverter Control Board finds extensive use in most industries dependent on automation, hence precision motor control:

Industrial Manufacturing

- Ensures consistent motor speed control in:

- Conveyors

- Packaging lines

- Assembly machinery

Marine & Offshore Equipment

Used in motor-driven applications requiring rugged and dependable performance.

HVAC Systems (Industrial Grade)

Supports fans, pumps, and blowers for controlled airflow and energy savings.

Oil & Gas Operations

Assists in regulation of motors in drilling, pumping, and refining systems.

Material Handling

Used in:

- Cranes

- Hoists

- Automated warehouse systems

- Automation Panels & Control Cabinets

- Supports long-standing VFD systems and electrical control panels.

Why Choose the Allen-Bradley 321131-A01?

1. Trusted Rockwell Automation Quality

Allen-Bradley products are known globally for their durability, safety, and long operational lifespan. This board is engineered for heavy-duty industrial use.

2. High Reliability in Critical Operations

The 321131-A01 ensures consistent performance, making it ideal for industries where downtime is costly and unacceptable.

3. Compatible with Various Allen-Bradley VFD Systems

Its broad compatibility makes it a preferred replacement part for engineers, technicians, and maintenance teams.

4. Improved Motor Performance

The board, thanks to the precise control algorithms, enables:

- Smooth start-up

- Stable torque control

- Reduced energy consumption

5. Cost-Efficient Replacement Component

Instead of replacing the entire inverter, replacing only the control board is a more economical and efficient solution.

6. Easy Integration & Servicing

Designed with user-friendly layout, it simplifies installation, diagnostics, and repair tasks.