| Attribute | Value |

|---|---|

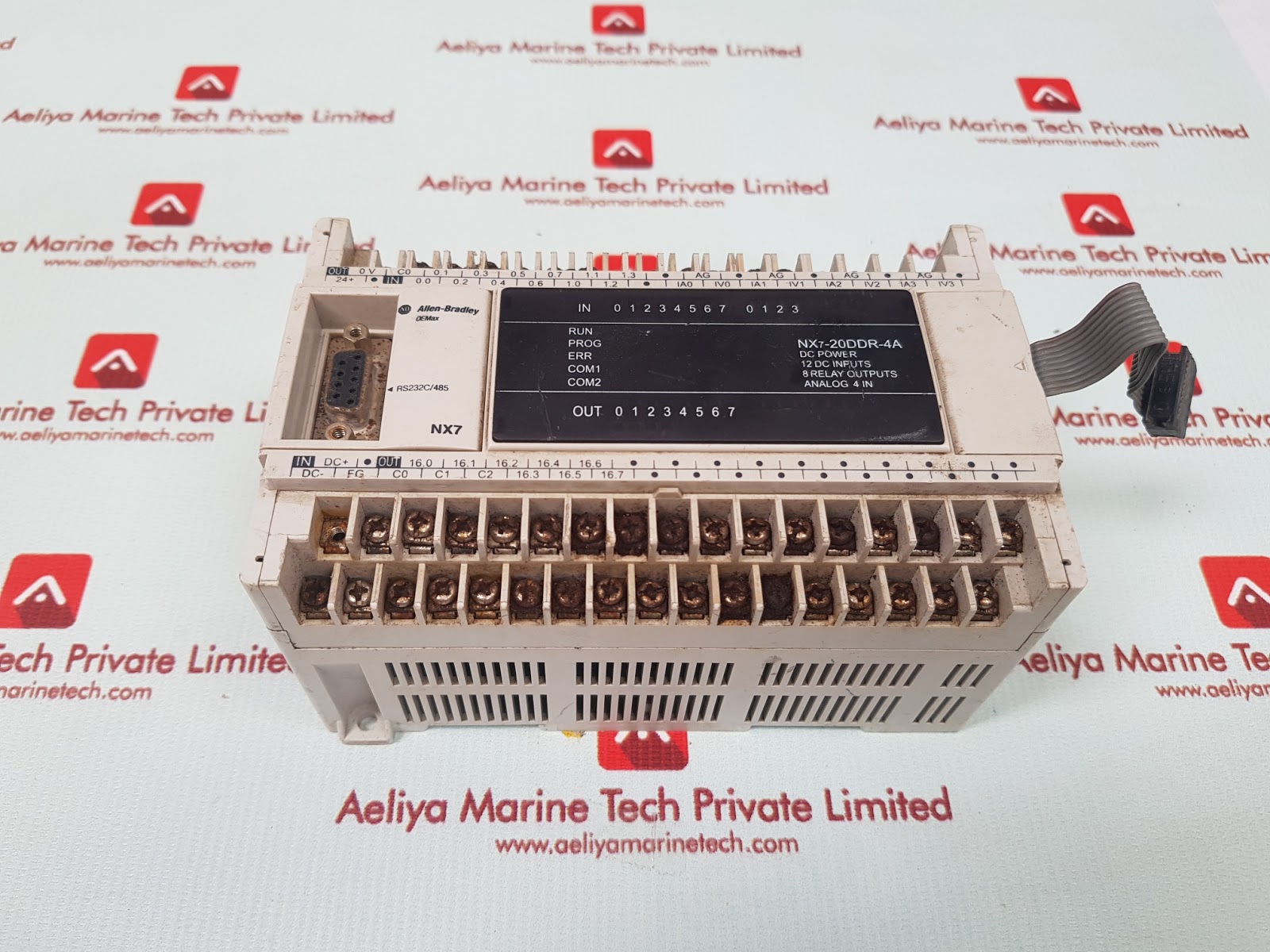

| Product Title | Allen-Bradley Bulletin 2001 NX7 NX7-20DDR-4A PLC Servo Driver |

| Brand | Allen-Bradley / OEMAX |

| Model | NX7 PLC – NX7-20DDR-4A |

| Bulletin Number | 2001 |

| Firmware Version | F/W: 2.42 |

| Power Supply | PWR: 24VDC, 29.5W, Class 2 |

| Inputs | 12 DC Inputs (24VDC, 10mA/Ch) |

| Analog Inputs | Analog 4 Channels (AI 4CH) |

| Outputs | 8 Relay Outputs (250VAC / 30VDC, 2A/Ch) |

| Communication Ports | RS232C / RS485 |

| Catalog Number | CAT. NO: 2001-NX7 20DDR4A |

| Series | SER: A |

| Revision | REV: C |

| Country of Origin | Made in Korea |

| Weight | 550 gm |

What is the Allen-Bradley Bulletin 2001 NX7 PLC Servo Driver?

The Bulletin 2001 series NX7 PLC Servo Driver manufactured by Allen-Bradley is an intelligent motion control interface module for PLC-based systems. It is designed to provide controlled operation of servo motors toward maintaining the exact positioning, speed control, and stability required in industrial processes.

This servo driver is known for:

- Efficient integration into PLC architectures

- Smooth operation for DC inputs and relay outputs

- Ability to handle analog signals flexibly

- Compatibility with automation and machine-control environments

The oxygen sensor is designed to deliver continuous industrial performance and maintains its accuracy and stability, even under demanding conditions.

Key Features of the Allen-Bradley 2001 NX7 PLC Servo Driver

1. PLC-Based Motion Control: Reliable

The driver works in a PLC system and provides precision control to the servo motors used in automation and machinery.

2. Multiple Input & Output Options

- 12 DC inputs

- 8 relay outputs

- 4 analog input channels

It makes the unit flexible for a wide range of control and signaling needs.

3. Steady DC Power Requirements

- Operates on 24V DC

- Power Consumption: 29.5W

- Relay output rating: 250VAC / 30VDC, 2A per channel

These ratings provide compatibility with standard automation control panels.

4. Compact & Durable Design

A robust construction supports harsh industrial conditions, vibration, and long hours of operation.

5. Communication & Firmware Integration

With its firmware versioning, such as F/W 4.11, the unit fits well with the legacy and semi-modern automation systems.

6. Easy Integration With Allen-Bradley Ecosystem

It supports quick, hassle-free installation with other Allen-Bradley controllers and components.

Applications of the Allen-Bradley Bulletin 2001 NX7 Servo Driver

The Servo Driver NX7 is widely used in industries where their traits of precision, reliability, and stable automation control are highly required.

Common Applications Include:

1. Manufacturing & Assembly Lines

Controls motor-driven systems that demand precision speed and position control.

2. Packaging Machines

Ensures smooth, synchronized movements that are required in conveyors, cutters, and handling mechanisms.

3. Robotics & Automation Cells

Supports robotic arms, pick-and-place units, and automated production modules.

4. CNC & Motion-Based Machinery

Great for servo motor control applications in machines for machining, cutting, bending, and shaping.

5. Marine & Industrial Control Panels

Applied in environmental systems, in machinery automation, and in complicated multi-input control panels.

6. Conveyor and Material Handling Systems

It helps in sustaining constant speed, torque, and accuracy of movement.

Why Choose the 2001 NX7 PLC Servo Driver by Allen-Bradley?

Industrial-grade reliability that’s trusted.

Components from Allen-Bradley have universal recognition for durability and long service life; they are, therefore, ideal for critical machinery.

Easy Replacement for Legacy Systems

Many industries still utilize the earlier automation systems. The NX7 servo driver is a perfect replacement for them without redesigning the whole setup.

High Compatibility With PLC Systems

Saves time and engineering cost because it seamlessly integrates into existing Allen-Bradley control architectures.

Stable Performance With Minimal Downtime

With its sturdy build and reliable performance, it will prevent downtime in high-demand settings.

Supports complex automation needs

The device handles different control logic requirements with digital inputs, relay outputs, and analog channels.

Cost-Effective Industrial Solution

Normally, choosing a tested and reliable unit often reduces maintenance cost and extends the machine’s life.