| Attribute | Value |

|---|---|

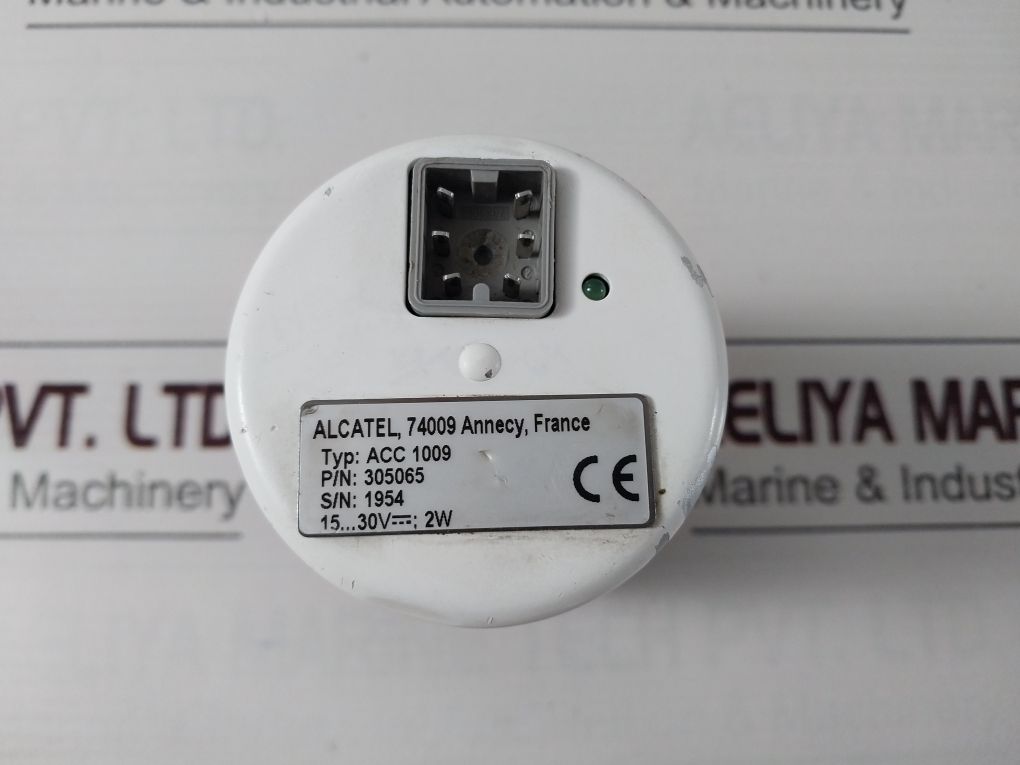

| Manufacturer | Alcatel |

| Type | Acc 1009 |

| Part Number | 305065 |

| Voltage | 15…30V —; 2W |

| Country of Origin | France |

| Weight | 670 Gm |

| Reference Number | 70322 |

What is the Alcatel ACC 1009 Vacuum Gauge?

The Alcatel ACC 1009 is a precise vacuum gauge instrument. It serves as a vital measuring tool, particularly in different types of manufacturing like semiconductor industries, scientific investigations, and other industrial processes. Due to advanced technology and being solidly constructed, this tool measures vacuum pressures very accurately for optimal system operation and reliability.

Features

High Accuracy: The Alcatel ACC 1009 has high accuracy pressure readings, ensuring the best performance in vacuum applications.

Durability: It is built with high-quality materials to withstand demanding environments and long-term usage.

User-Friendly Interface: The device is easy to install and operate, making it accessible for both experts and newcomers in vacuum technology.

Versatile Applications: Suitable for various industries, including research labs, medical devices, and industrial vacuum processes.

Reliable Performance: Consistent readings ensure that the system remains stable and efficient.

Advantages of Alcatel ACC 1009 Vacuum Gauge

1. Better System Monitoring

Accurate pressure readings ensure that your vacuum system operates within optimal parameters, thus reducing the risk of inefficiencies and failures.

2. Better Process Control

With precise vacuum measurement, you can fine-tune your processes, leading to better product quality and consistency.

3. Cost Efficiency

By preventing system failures and inefficiencies, the ACC 1009 reduces maintenance costs and operational downtime.

4. Extended Equipment Lifespan

Consistent monitoring of vacuum pressure prevents potential damage to other components in the system, thereby prolonging equipment longevity.

Applications of the Alcatel ACC 1009 Vacuum Gauge

This vacuum gauge is widely used in multiple fields, including:

Semiconductor Manufacturing: Ensures precision in vacuum-dependent fabrication processes.

Research Laboratories: Provides reliable readings for scientific experiments requiring controlled environments.

Industrial Processing: Helps in vacuum-based production techniques.

Medical Equipment Manufacturing: Maintains sterile and controlled conditions.

Aerospace Engineering: It is essential for vacuum testing and space simulation experiments.

Reviews

There are no reviews yet.