| Attribute | Value |

|---|---|

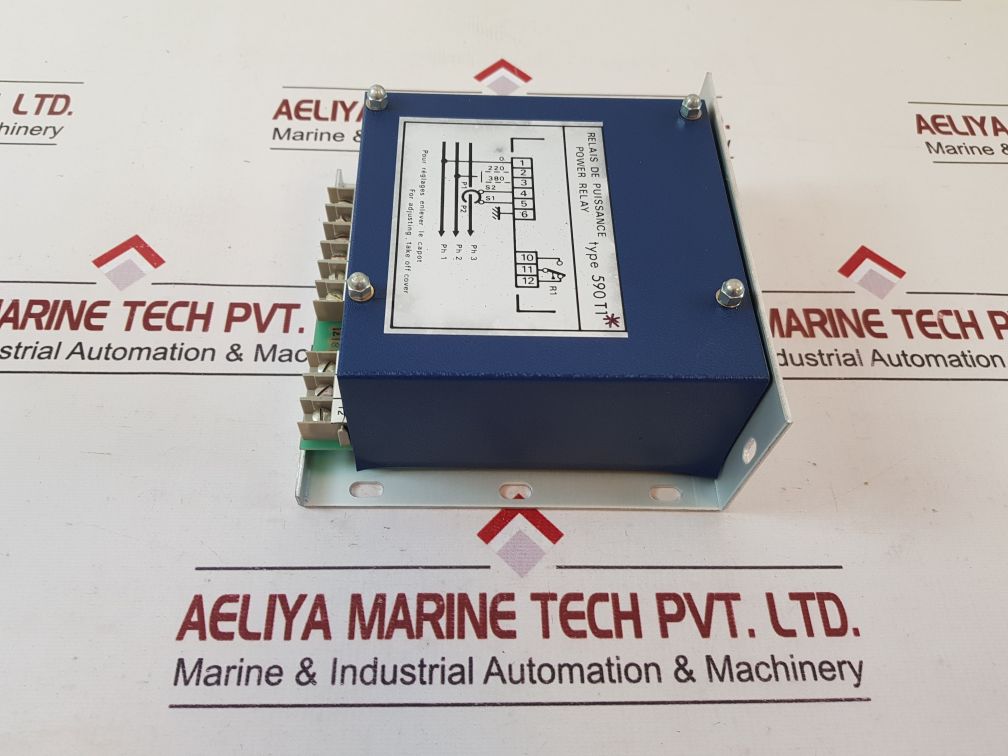

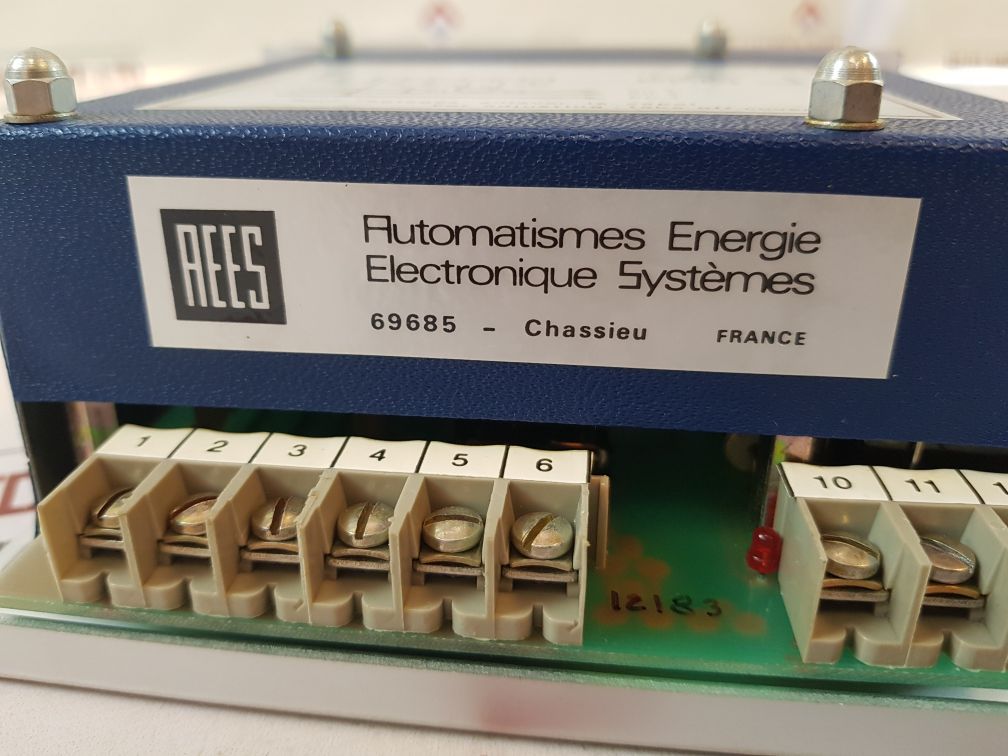

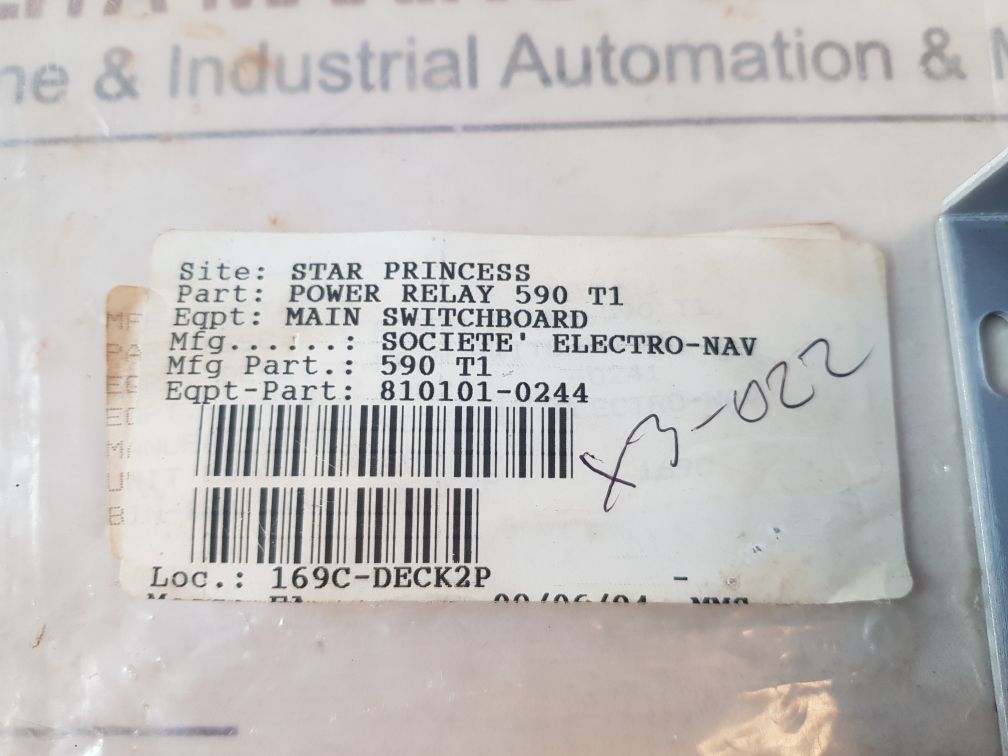

| Manufacturer | Société Electro-Nav |

| Brand | AEES |

| Full Name | Auto matismes Energie Electronique Systèmes |

| Type/MFG Part | 590 T1 |

| Part Name | Power Relay 590 T1 |

| Equipment | Main Switchboard |

| Equipment-Part | 810101-0244 |

| Country | France |

| Weight | 990 g |

| Condition | New |

| Reference Number(S) | 44393 |

What is a power relay?

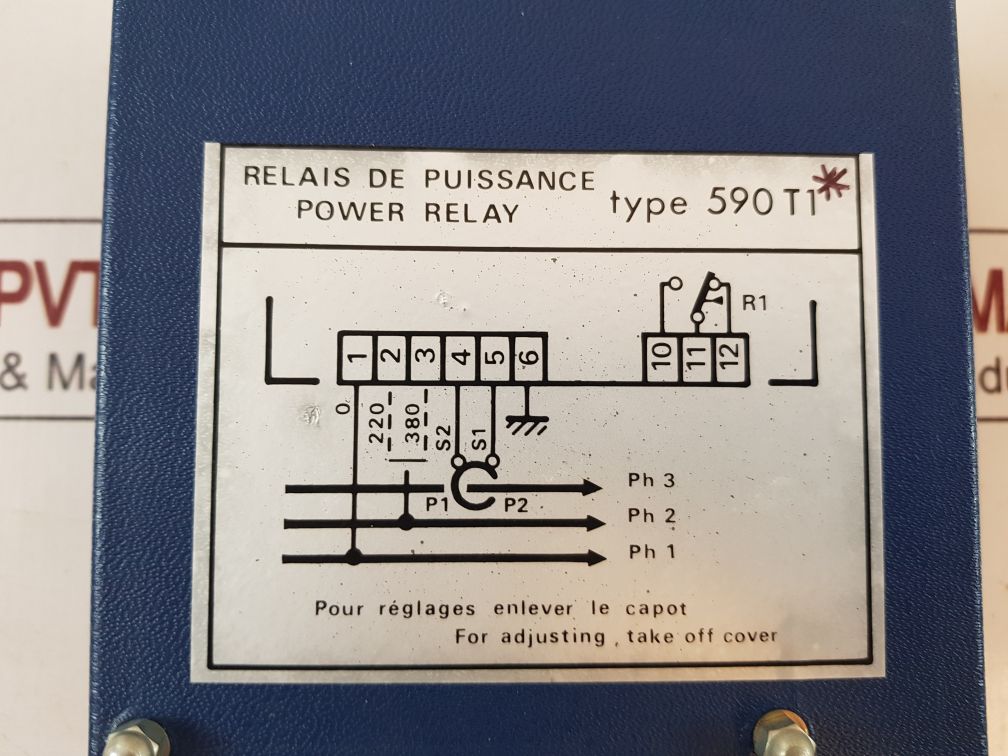

An electrically operated switch in which a low-power signal or circuit controls a higher-power circuit, rather than flipping a switch or feeding high current directly into sensitive control electronics, a relay uses electromagnetic or solid-state means to create an on/off control mechanism. In this case, the AEES 590 T1 Power Relay is designed with specific voltage and current requirements that will provide an assured bridge for control logic with heavy loads.

Key Features of AEES 590 T1

Robust Construction: The AEES 590 T1 is designed to carry heavy electrical loads, thus avoiding damage or premature failure. The internal components, including the coil, armature, and contacts, are made from high-quality materials that ensure longevity.

High switching capacity: The contacts are designed to withstand high voltage and current, which means this relay is capable of switching for a wide range of applications. It can power your motors, heating elements, or other components with high demands with the assurance that it can switch them in time.

Compact Size: Although the AEES 590 T1 is quite robust in capabilities, it is relatively compact in size. This small footprint makes it easy to integrate into control panels, circuit boards, and other electronic designs without compromising space.

Low Coil Power Consumption: The coil of the relay is designed to consume very low power to activate. This reduces the overall energy consumption of the system, making it more efficient and lowering operational costs—especially in large-scale or battery-powered setups.

Safety Compliance: Power relays must adhere to strict safety standards. The AEES 590 T1 usually complies with relevant industry certifications, making it suitable for projects that need to pass regulatory approvals.

Applications

Industrial Machinery: Big motors, pumps, and conveyors require strong switching solutions for heavy power loads. The AEES 590 T1 is reliable enough to maintain smooth running of manufacturing processes.

Automotive Systems: Modern vehicles employ a number of electronic systems that rely on relays to control high-current devices like headlights, air conditioning units, and engine controls. The AEES 590 T1 ensures consistent performance under these demanding conditions.

HVAC and Building Controls: Heating, ventilation, and air conditioning systems often rely on power relays for driver compressors, fans, and blowers. The AEES 590 T1 would be appropriate for these applications because of its higher switching capability and toughness.

Renewable Energy Installations: Solar and wind power systems often require relays to control power routing and system protection. The AEES 590 T1 can ensure stable operation and facilitate maintenance in such installations.

Home Automation: Relays are commonly used in lighting controls, security systems, and smart home applications. The AEES 590 T1 can be a reliable interface between control boards and high-power devices.

Advantages of Using AEES 590 T1

Improved Reliability: Taking high-power switching duties off your control components reduces wear and tear, thereby minimizing system failures and increasing equipment life.

Improved Safety: Separation of control circuits from high-power circuits will help protect operators and sensitive electronics from electrical hazards.

Easy Maintenance: Relays are easier to troubleshoot or replace than other solid-state switching components. Modularity can save you time and labor costs.

System Flexibility: Because power relays of AEES 590 T1 can be found with different coil voltage options and configurations, you can match them precisely according to your project or device needs.

Cost-Effectiveness: Power relays are often a relatively cost-effective component and hence engineers opt for them to balance performance with budgetary pressures.