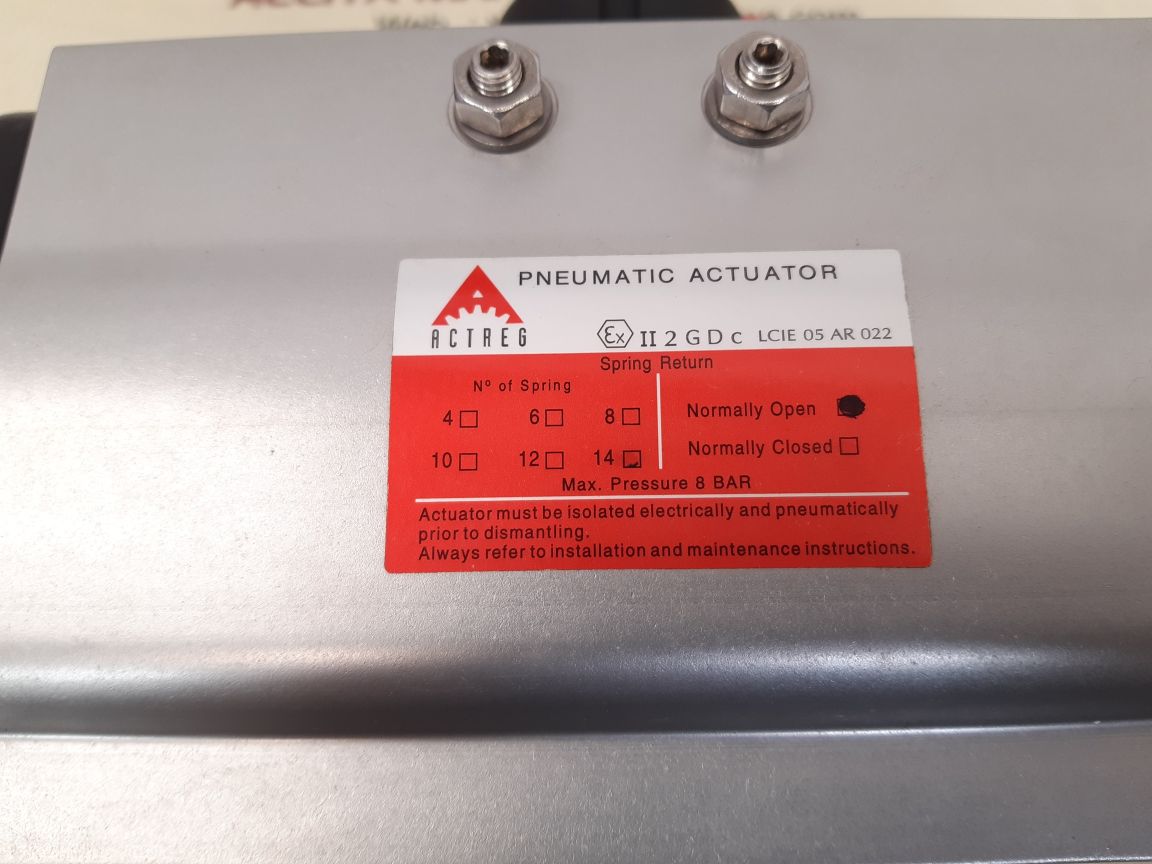

| Attribute | Value |

|---|---|

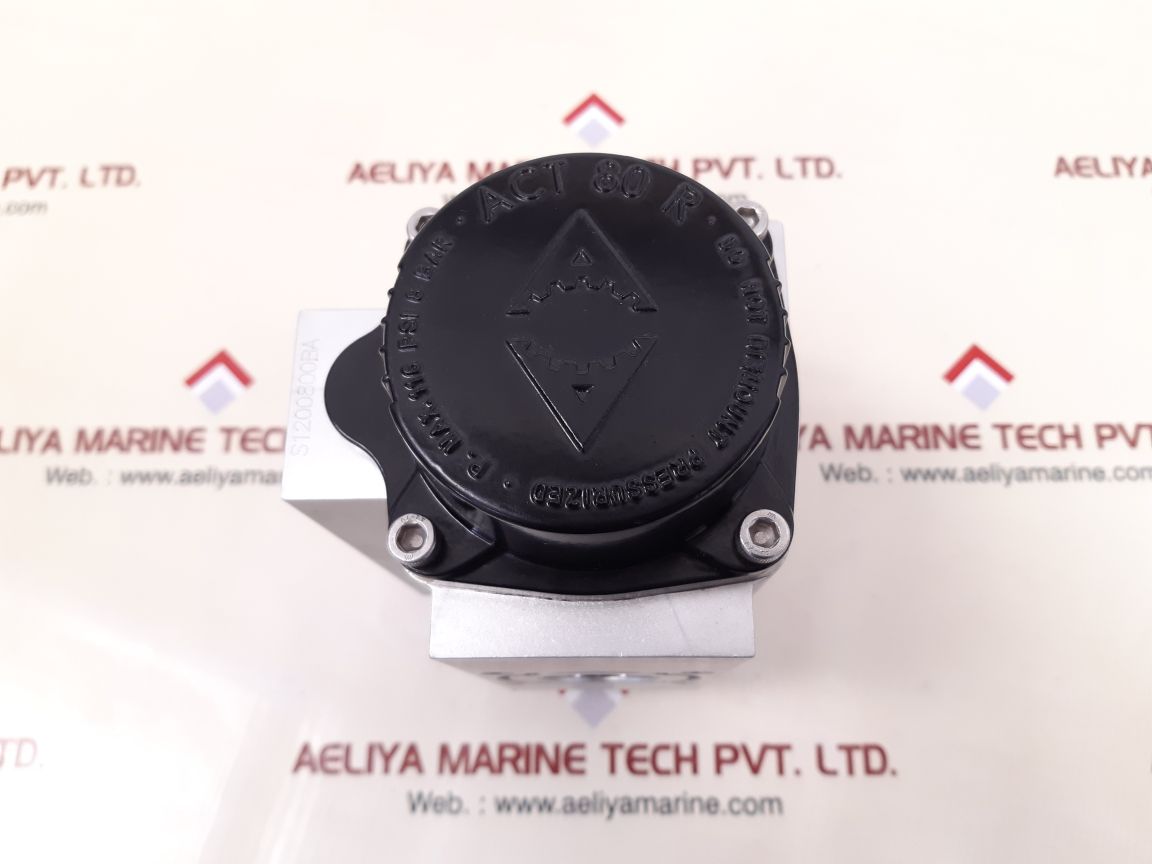

| Product Name | Actreg ACT 80R Pneumatic Actuator |

| Brand | Actreg |

| Type | Pneumatic Actuator |

| Certification | EX II 2 G D C LCIE 05 AR 022 |

| Maximum Pressure | 8 bar |

| Max Pressure (PSI & Bar) | 116 PSI & Bar |

| Model | ACT 80 R |

| Weight | 3.580 kg |

What is the ACTREG ACT 80R Pneumatic Actuator?

The ACTREG ACT 80R is a rack-and-pinion type of pneumatic actuator that translates compressed air energy into mechanical motion in order to drive quarter-turn valves, like ball valves and butterfly valves. This actuator guarantees quick and dependable valve operation, making it a great fit for industries that need precision and efficiency.

It is offered in both double-acting and spring-return types, allowing for flexibility depending on various industrial requirements.

How Does the ACT 80R Pneumatic Actuator Operate?

The ACT 80R actuator functions on the pneumatic principle, wherein compressed air is employed to generate linear or rotary motion. Here is how it works:

Air Supply & Motion Generation:

- Compressed air is fed into the actuator, driving the internal pistons apart (in double-acting types) or winding return springs (in spring-return types).

- This motion is transferred to a rack-and-pinion mechanism that turns the output shaft.

Valve Operation:

- The rotary motion of the output shaft is utilized to open or close the valve.

- In a double-acting actuator, air is fed to both sides of the pistons for movement in both directions.

- In a spring-return actuator, the pistons are pushed by compressed air in one direction and are returned to the original position by pre-loaded springs when the air is withdrawn.

Position Feedback & Control:

- The actuator may be fitted with position indicators, limit switches, and solenoid valves for remote control and automation.

Key Features of the ACTREG ACT 80R Pneumatic Actuator

The ACT 80R features a number of excellent attributes that make it an industrial favorite:

1. Superior Construction

Constructed from corrosion-resistant materials like anodized aluminum or stainless steel, providing long service life in hostile environments.

2. Rack-and-Pinion Construction

Offers effective torque output, providing smooth and accurate valve movement.

3. Double-Acting & Spring-Return Options

Double-Acting: Operates using air pressure to open and close the valve.

Spring-Return: Operates with air pressure for the one stroke and springs for the return stroke to guarantee fail-safe operation.

4. Compact & Lightweight

Ergonomic design minimizes space requirement while keeping power output high.

5. ISO 5211 Mounting Interface

Universal mounting facilitates simple mounting on a variety of valves.

6. High Torque Output

Able to sustain high-torque applications efficiently.

7. Temperature & Pressure Resistance

Able to function under harsh temperature conditions and support high-pressure applications.

8. Accessories & Customization

Compatible with positioners, limit switches, solenoids, and manual overrides for premium control features.

Benefits of the ACTREG ACT 80R Pneumatic Actuator

Quick & Efficient Action – Provides rapid valve actuation with reduced delay.

Energy-Saving – Makes efficient use of compressed air, saving energy.

Low Maintenance – Robust design reduces maintenance requirements and expenses.

Secure & Fail-Safe Design – Spring-return facility provides fail-safe operation on loss of air supply.

Simple Mounting – ISO standard mounting ensures easy mounting with current valve configurations.

Uses of the ACTREG ACT 80R Pneumatic Actuator

Due to its reliability and efficiency, the ACT 80R is used extensively in various industries, including:

1. Oil & Gas Industry

- Operates flow valves in pipelines and refineries.

- Provides safety through fail-safe operation.

2. Water Treatment Plants

- Controls water and wastewater flow.

- Utilized in filtration and chemical treatment processes.

3. Power Plants

- Operates steam and fuel valves in nuclear and thermal power plants.

4. Food & Beverage Industry

- Applied in sanitary and hygienic valve control applications.

- Assists in automated liquid processing systems.

5. Chemical & Pharmaceutical Industry

- Operates aggressive chemicals in reactors and pipelines.

- Applied for precision-controlled dosing and mixing.

6. HVAC Systems

- Regulates air and fluid flow in heating, ventilation, and cooling systems.

How to Select the Right ACTREG Pneumatic Actuator?

When choosing a pneumatic actuator

✔ Torque Requirements – Make sure the actuator delivers enough torque for your valve.

✔ Operating Pressure – Verify compatibility with your system’s air pressure range.

✔ Mounting Interface – Make sure it is compatible with your valve’s mounting standard (ISO 5211).

✔ Environmental Conditions – Take into account temperature, humidity, and corrosion resistance.

✔ Control & Accessories – Decide if you require positioners, limit switches, or solenoid valves.