| Attribute | Value |

|---|---|

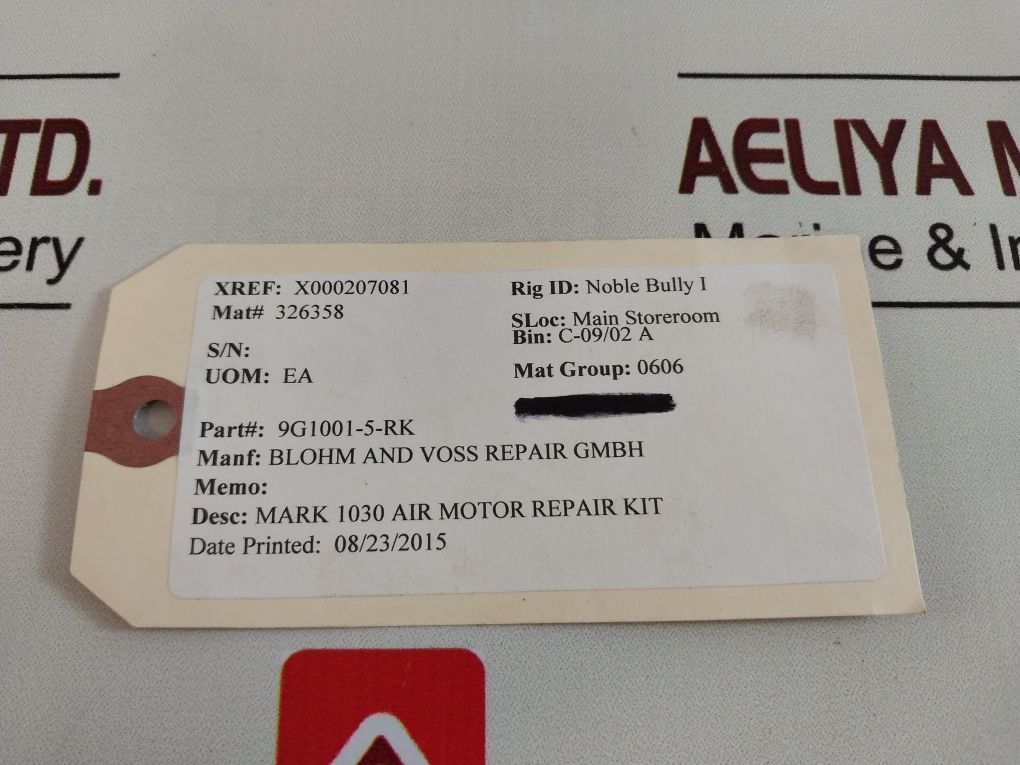

| Product Name | 9G1001-5-RK Mark 1030 Air Motor Repair Kit |

| Manufacturer | Blohm and Voss Repair GmbH |

| Brand | Interface Solutions |

| Part Number | 9G1001-5-RK |

| Description | Mark 1030 Air Motor Repair Kit |

| Cross Reference | X000207081 |

| Material Number | 326358 |

| Model | N-8092 |

| Component | Gaskets |

| Bearing Type | 6204Z |

| Country of Origin | Made in USA |

| Weight | 370 gm |

| Reference Number | 60097 |

What Is the 9G1001-5-RK Mark 1030 Air Motor Repair Kit?

The repair kit 9G1001-5-RK for Mark 1030 Air Motor is a special service kit intended to restore, overhaul, and extend the life of Mark 1030 air motors. Since air motors run on the principle of compressed air, the internal components of air motors, such as vanes, seals, bearings, and gaskets, experience heavy wear and tear due to continuous friction and load cycles.

This repair kit provides the replacement parts necessary to return the air motor to the original level of performance. The kit restores torque, consistency, efficiency, and smooth rotation by replacing worn components across a range of operating conditions.

This is a common operation in preventive maintenance or complete motor refurbishing to minimize downtime, assure stable output, and long-term operational reliability.

Key Features of the 9G1001-5-RK Mark 1030 Air Motor Repair Kit

1. Complete Component Set for Full Overhaul

The kit generally consists of all basic wear parts like vanes, seals, O-rings, gaskets, bearings, and retaining parts for a complete and effective repairing process.

2. Designed Specifically for Mark 1030 Air Motors

All parts are dimensionally accurate and designed to match the specifications of Mark 1030 air motors for proper fit and functionality.

3. Improves Motor Performance

This usually restores the air motor to its originally specified torque output, speed accuracy, and smooth rotational performance.

4. Improves Efficiency and Reduces Air Consumption

Worn vanes or seals result in air leakage and energy being wasted. The kit helps restore optimum air sealing, thus lowering operating costs.

5. Built With High-Quality Materials

Every component in it is made from high-quality industrial-grade materials capable of withstanding high friction, extreme changes in temperature, and continuous air pressure.

6. Supports Preventive Maintenance Programs

By using the kit periodically, many industries will be able to avoid sudden breakdowns and lengthen the life of expensive air motors.

7. Easy to Install

The parts are designed with easy assembly in mind, cutting down maintenance time and making it easier for technicians to perform repairs.

Applications of the 9G1001-5-RK Mark 1030 Air Motor Repair Kit

The kit is used wherever Mark 1030 air motors are operating. The motors are widely deployed in:

1. Marine and Shipboard Operations

Air motors are preferred in marine environments because of safety, moisture resistance, and spark-free operation. This repair kit helps maintain uninterrupted functioning in critical shipboard applications such as:

- Winches

- Hoists

- Pumps

- Valve actuation systems

2. Industrial Automation & Manufacturing

Air motors power a variety of industrial tools and equipment utilized in production, assembly, and repetitive operations. The repair kit maintains motors used in:

- Conveyor drives

- Material handling equipment

- Machinery relating to mixing and blending

- Packaging lines

3. Hazardous or Explosive Environments

Specific industries needing non-electrical drive systems include:

- Oil & gas

- Chemical plants

- Mining environments

- Paint shops

The repair kit ensures that air motors remain safe and functional under such demanding conditions.

4. Heavy-Duty Tools & Pneumatic Equipment

Mark 1030 motors power most grinding, drilling, cutting, and polishing tools. This repair kit maintains their consistency and output.

5. Food & Beverage Processing

Air motors are suitable for hygienic and wash-down applications. The repair kit supports continuous maintenance for equipment operating under harsh cleaning conditions.

Why Choose the 9G1001-5-RK Mark 1030 Air Motor Repair Kit?

1. Cost-Effective Alternative to Full Motor Replacement

Rather than buying a new motor, the replacement of critical internal components can restore performance at a fraction of the cost.

2. Reduces Downtime

Quick repairs and regular, predictable maintenance help avoid unexpected stoppages and lost productivity.

3. Ensures High Performance & Reliability

Rebuilt motors provide consistent torque, speed, and efficiency, which is very important in operations that rely on precision.

4. Extends Motor Service Life

With routine maintenance using this repair kit, air motors can expect to stay operational many years beyond their normal life expectancy.

5. Suitable for Extreme Conditions

The components are designed to withstand harsh industrial environments, and therefore this kit is ideal for heavy-duty applications.

6. Trusted by Marine, Industrial & Process

Industries Compatibility and durability make it a reliable choice for companies that wish to perform durable and long-lasting motor repairs.