What Are Industrial Blocks?

Industrial blocks refer to a variety of modular units, systems, or components that work together to facilitate specific functions in an industrial setup. These blocks may include electrical, mechanical, hydraulic, or software-based systems, depending on the application. For example, in automation, an industrial block could be a programmable logic controller (PLC), a variable frequency drive (VFD), or even a sensor module.

These blocks are designed to be interchangeable, adaptable, and scalable, making them indispensable in industries such as manufacturing, marine, energy, and construction.

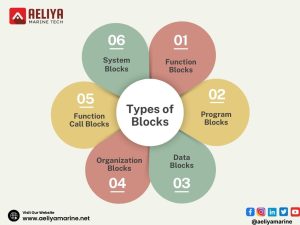

Types of Industrial Blocks

- Electrical Blocks

- PLC Modules: Used for automating machinery and processes.

- Relay Modules: Essential for controlling circuits.

- Circuit Breakers: Provide safety by preventing electrical overloads.

- Mechanical Blocks

- Gear Systems: Integral to motion and force transmission.

- Bearings and Shafts: Ensure smooth mechanical operations.

- Hydraulic and Pneumatic Blocks

- Valves and Actuators: Control fluid flow in hydraulic or pneumatic systems.

- Pressure Regulators: Maintain optimal pressure for machinery operations.

- Software and Control Blocks

- Human-Machine Interfaces (HMIs): Allow operators to interact with machines.

- Supervisory Control and Data Acquisition (SCADA): Provides monitoring and control capabilities for large-scale operations.

Importance of Industrial Blocks

- Modularity and Scalability Industrial blocks are designed to be modular, which means they can be easily added or removed without disrupting the entire system. This feature is crucial for industries that frequently upgrade or expand their operations.

- Efficiency By streamlining complex processes into manageable units, industrial blocks improve operational efficiency. For instance, a well-designed PLC module can reduce downtime and enhance productivity in a factory.

- Reliability High-quality industrial blocks are built to withstand harsh conditions, ensuring consistent performance even in demanding environments.

- Cost-Effectiveness Modular designs allow for cost-effective maintenance and upgrades, as individual components can be replaced or updated without overhauling the entire system.

Applications of Industrial Blocks

- Manufacturing

- Used in assembly lines to automate repetitive tasks.

- Ensure precision in machining and welding operations.

- Marine Industry

- Control systems for ship navigation and propulsion.

- Automation blocks for cargo handling.

- Energy Sector

- Power distribution and monitoring systems.

- Renewable energy setups like wind turbines and solar farms.

- Construction

- Automation in heavy machinery like cranes and bulldozers.

- Hydraulic systems for excavation and material handling.