What Is an Industrial Transformer?

An industrial transformer is the electrical device which transfers electrical energy between two or more circuits using electromagnetic induction. In other words, it raises or lowers voltage levels depending upon the requirements of the machines and equipment to be powered. Generally, different machines in an industry require different voltages. Industrial transformers change the electrical energy to the proper voltage so that the performance will be at an optimal level and will be safe to use.

Why Are Industrial Transformers Important?

Voltage Management: Machines in industrial facilities operate at different voltage levels. One piece of equipment may require a high voltage for heavy-duty tasks, while a sensitive device may need a lower voltage to avoid damage. A transformer adjusts the voltage to the correct level, so each piece of equipment runs smoothly and safely.

Operational Efficiency: Transformers ensure less energy wastage by providing the required voltage. A machine receiving more voltage than what it requires can run inefficiently or burn out faster. If a machine does not receive the required voltage, it can end up not running at full capacity and thereby decrease productivity.

Safety: High-voltage electricity is dangerous. Industrial transformers help isolate and contain voltage levels in specific parts of a facility, thereby reducing risks to workers and equipment.

Reliability: Frequent power fluctuations can harm industrial operations. Transformers help regulate power flow and stabilize electricity supply, thereby reducing downtime and helping to maintain consistent production.

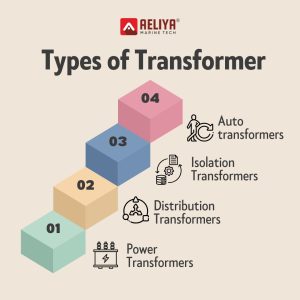

Types of Industrial Transformers

Power Transformers

Purpose: These are mainly used in transmission networks since they transfer loads of power over high voltages.

Key Feature: They must be able to carry heavy loads with minimal loss.

Application: Power generation plants, grid substations, and high-voltage areas for transmission purposes.

Distribution Transformers

Purpose: These are used for reducing the very high voltage supplied by the transmission line to lower voltage levels that could be used either industrially or commercially.

Key Feature: 24/7 operation means it is essential for efficiency and with low maintenance requirements.

Application: Factories, commercial buildings, and smaller electric networks.

Isolation Transformers

Purpose: To isolate or “isolate” one portion of the circuit from another for the protection of sensitive equipment.

Key Feature: They do not allow power surges and remove electrical noise.

Application: Equipment that requires a stable power supply, such as advanced control systems, testing equipment, or lab instruments.

Autotransformers

Purpose: A more economical and compact solution for stepping voltage up or down within a smaller range.

Key Feature: They share common windings, which reduces the size and cost but does not provide isolation.

Application: When small changes in the voltage are necessary.

Specialty Transformers

Purposes: Designed for unique processes and special industrial needs.

Examples: Furnace transformers for steel plants, rectifier transformers for electrochemical processes, etc.

Key Factors When Selecting an Transformer

Voltage Requirements

Every industrial operation has different voltage requirements. Determine if you require a step-up or step-down transformer, or if special isolation is needed.

Power Rating

This is measured in kVA (kilovolt-amperes) or MVA (megavolt-amperes). The transformer must be able to handle the maximum load expected without overheating or compromising efficiency.

Efficiency

Transformers can lose energy through heat and magnetism. High-efficiency transformers save money in the long run by reducing wasted energy.

Cooling Method

Transformers produce heat and require appropriate cooling to function well:

Oil-Immersion: Suitable for high power transformers; the oil serves as an insulation and cooling agent.

Air-Cooled (Dry-Type): Suitable for low-power, indoor installations where fire protection is a major concern.

Environmental Conditions

Severe temperature, high moisture, or dirty environment may degrade transformer performance. Select a type that can handle specific site conditions (sealed or weatherproof enclosures).