Drives are essential components in various industrial and commercial applications, controlling the speed, torque, and direction of motors. They play a crucial role in energy management, automation, and machinery optimization. In this blog, we’ll explore what drives are, their types, applications, benefits, and how they shape modern technology.

What Are Drives?

A drive is an electronic device or system used to control the operation of an electric motor. It adjusts the motor’s speed, torque, and direction according to the needs of the application. Drives are the interface between a control system and a motor and are thus indispensable in industrial automation and energy-efficient solutions.

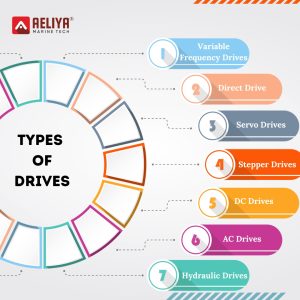

Types of Drives

1. Variable Frequency Drives (VFDs):

Function: Control the speed and torque of AC motors through the adjustment of frequency and voltage power.

Applications: HVAC, conveyor belts, pumps, and fans apply for exact speed control and saving energy.

2. Servo Drives:

Function: Control the speed and torque of DC motors by varying the voltage or current.

Applications: Common in elevators, cranes, and rolling mills where torque control is critical.

3. Stepper Drives:

Function: Control stepper motors by supplying pulses for discrete movement.

Applications: Ideal for 3D printers, automated machining tools, and precision positioning systems.

Applications of Drives

Drives are ubiquitous in industries and everyday life. Here’s where you’ll commonly find them:

Industrial Automation:

Drives are the driving force of automated production lines, ensuring precise motor functioning for assembly, packaging, and material handling.

Energy Management:

Through motor performance optimisation, drives enable minimizing energy consumption in HVACs, water pumps, and wind turbines.

Transport:

Drives manage the propulsion systems of electric vehicles, trains, and escalators by ensuring smooth operation and a better efficiency level.

Renewable Energy:

Drives ensure constant and efficient conversion as well as distribution of wind turbine and solar panel energy

Marine Applications:

Drives are very essential for ship propulsion, winches, and onboard equipment as it improves fuel efficiency and operating control.

Advantages of Using Drives

Energy Efficiency:

The use of drives reduces power consumption. The motor speed is matched with the application requirement, resulting in considerable cost savings.

Improved Performance:

The precision control over motor speed and torque improves the performance of machines and systems.

Reduced Wear and Tear:

The drives ensure smooth start and stop operations without mechanical stress on motors and increase their life span.

Flexibility:

Drives are easily changed for speed and direction, and so they are used for many applications.

Cost Saving:

While drives are an initial investment, they are more efficient and have lower energy costs, so they do have long-term cost saving benefits.

Drawbacks of Drive Systems

Despite the above advantages, there are some disadvantages in implementing drive systems:

Initial Costs:

Drives can be costly to acquire and install, especially high quality ones.

Complexity:

Most people will need technical knowledge when installing and configuring drives.

Maintenance:

Proper maintenance and troubleshooting will ensure optimum performance.

Harmonics:

Harmonics from drives can create additional requirements for filtering solutions in power systems.

The Future of Drives

Drive technology advancement is closely associated with advancements in electronics, automation, and energy systems. Some emerging trends are:

Smart Drives:

IoT and AI-based real-time monitoring, predictive maintenance, and data-driven decision-making

Eco-Friendly Solutions:

Optimization of drives for renewable energy applications and reduction of carbon footprint.

Compact Designs:

More compact and efficient drives are designed for space-constrained environments.

Wireless Control:

Better connectivity for remote monitoring and control is now a standard feature.