Converters are integral parts of today’s industrial and technological worlds. While they help energize electronic equipment, they also allow for intercommunication between system after system. In this blog, we explain what converters are, what categories of converters exist, how they work, and why they are crucial in both industries and homes.

What is a Converter?

A converter is a device or system that converts a form of energy, signal, or data from one into another. It makes the input compatible with the desired output requirements, like voltage, current, frequency, or data format. The conversion can occur in electrical, mechanical, or digital domains.

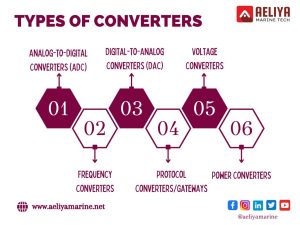

Types of Converters

Converters are available in several types, especially the one being suited to perform a particular task or an industrial application. Some of the most common types include;

1. Power Converters

Power converters are used to change the electrical energy provided for use in a particular system and enable it to be appropriate for the equipment at hand. Key types include:

AC to DC Converters (Rectifiers): This converts AC to DC for use in devices like laptops and batteries.

DC to AC Converters (Inverters): Convert DC back to AC for use in solar panels or UPS systems.

DC to DC Converters: Can step the DC voltage up or down depending on the requirements of devices with which it will be used.

AC to AC Converters: Change the frequency or voltage of AC power and are used in industrial motor speed controllers.

2. Signal Converters

Signal converters alter the form or nature of electrical signals. Such devices are essential in both communication and control systems. Some examples include:

- Analog-to-Digital Converters

- Digital-to-Analog Converters

3. Data Converters

Data converters facilitate communication between incompatible systems by changing information into forms that can be read. Some examples include:

- Networking protocol converters

- File format converters for documents or media

4. Frequency Converters

Frequency converters change the frequency of electrical power for use with different equipment, a common theme for industrial motor application.

5. Mechanical Converters

Mechanical converters change the form of mechanical energy, for instance, in gearboxes or torque converters.

How Do Converters Work?

A converter operates with a specific method according to its type but with the same general principle: it accepts an input in one way and processes it to yield the desired output. For example:

Power converters: employ electronic circuits and components, such as transformers, diodes, capacitors, so as to alter voltage and current.

Signal converters: operate with complex algorithms and integrated circuits to process the electrical signals.

Data converters: Data converters will use either software or hardware interfaces to reformat the information.

Applications of Converters

The applications of converters cover a wide range of fields, therefore an indication of their versatility:

Industrial Automation: Precision power and control for machinery

Renewable Energy Systems: Transformation of solar or wind power to electricity

Telecommunication: Processing of signals for data transmission

Consumer Electronics: Providing devices with appropriate levels of power.

Automotive: Enabling hybrid and electric vehicles to be operational.

Aerospace and Defense: Allowing the reliable operation of communication as well as control systems.

Benefits of Converter

Converters can offer many advantages, such as:

Efficacy in Energy Conversion: Minimize loss of energy in transformation.

Compatibility: Allowing diverse systems to work mutually.

Accuracy: Providing outputs that are precise to a given requirement.

Flexibility: Allowing equipment to operate under different conditions or with different power sources.

Future Trends of Converter Technology

The future of converters technology can be best described by innovation and sustainability

Smart Converters: IoT integration and AI-based automated control system

Energy Storage Integration: Combine with a battery in renewable energy systems.

Miniaturization: Smaller, more compact converters for portable electronics

Improved Efficiency: Advanced materials like silicon carbide (SiC) and gallium nitride (GaN) that reduce losses.