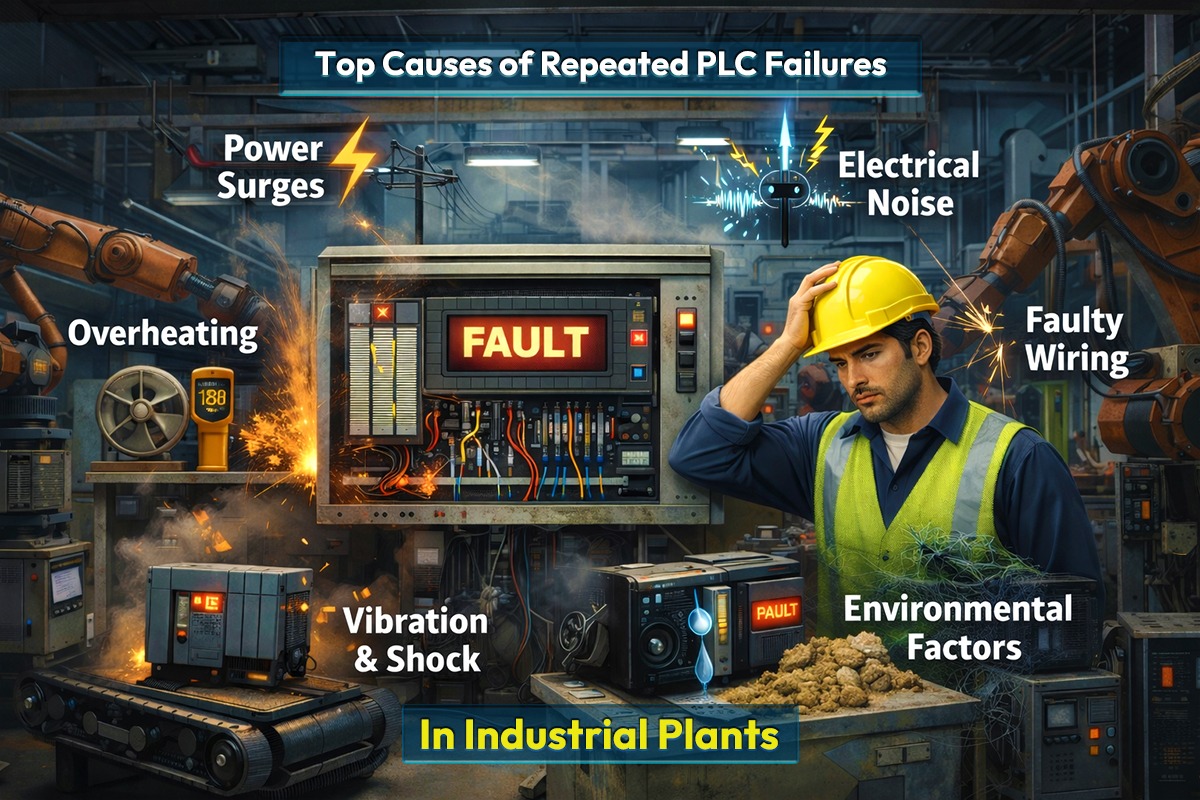

Top Causes of Repeated PLC Failures in Industrial Plants

Programmable Logic Controllers (PLCs) are the backbone of every modern industrial plant. From controlling motors and conveyors to managing safety systems and monitoring real-time processes, PLCs ensure smooth, uninterrupted operations. However, many facilities experience repeated PLC failures—leading to unexpected downtime, rising maintenance costs, and serious production losses.

What Are PLC Failures?

A PLC failure occurs when the controller or its associated modules stop functioning correctly, causing incorrect outputs, system errors, or complete shutdowns.

PLC failures can be:

Hardware-related

– CPU malfunction

– I/O module failures

– Power supply breakdown

– Damaged backplanes or connectors

Software-related

– Program corruption

– Incorrect logic

– Configuration mismatch

– Communication errors

Environmental or operational

– Excessive vibration

– Heat or moisture exposure

– Wiring issues

– Interference from other devices

Repeated failures indicate an underlying systemic issue, not just a one-time fault.

Key Causes of Repeated PLC Failures in Industrial Plants

Below are the most common reasons PLCs fail again and again:

1. Power Supply Instability

Unregulated power, sudden voltage spikes, or unreliable UPS systems can weaken PLC components over time.

Examples:

-

Brownouts or dips during peak load

-

Faulty earthing

-

High inrush currents

-

Unstable 24V DC supplies

Impact: CPU resets, corrupted logic, burnt components, unexpected machine stops.

2. Overheating and Poor Ventilation

PLCs continuously generate heat, and when enclosed inside panels with inadequate cooling, failure rates increase drastically.

Causes include:

-

Blocked ventilation fans

-

High ambient temperature near furnaces or motors

-

Dust accumulation on heat sinks

-

Panels exposed to direct sunlight

Impact: shortened component life, CPU errors, I/O malfunction.

3. Loose, Frayed, or Damaged Wiring

Improper cabling is one of the most overlooked causes of PLC failure.

Typical issues:

-

Vibration causing wire loosening

-

Corrosion in marine environments

-

Poor-quality cable lugs

-

Incorrect grounding or shielding

Impact: intermittent communication loss, false I/O readings, random shutdowns.

4. Electrical Noise & EMI Interference

Heavy machinery like VFDs, motors, welding sets, and solenoids generate electromagnetic noise.

If wiring is not properly shielded or separated from power lines:

-

PLC inputs misread signals

-

Analog values fluctuate

-

Communication networks drop packets

-

CPUs freeze or crash

EMI is especially common in marine and industrial automation plants with dense wiring.

5. Faulty or Aging I/O Modules

Even if the PLC CPU is healthy, repeated failures often originate from I/O modules that are overloaded or decades old.

Issues:

-

Input overvoltage

-

Output relay burnout

-

Overloaded analog channels

-

Damaged terminals from corrosion

Replacing only the CPU while keeping faulty modules leads to repeated system failures.

6. Poor Maintenance and Lack of Cleaning

Dust + humidity + heat = PLC destruction.

Regular cleaning, tightening, and inspection are often ignored in busy industrial plants.

Consequences include:

-

PCB short circuits

-

Fan failure

-

Terminal rusting

-

Sensor misreading

-

Board contamination

This is one of the cheapest causes to fix — but also one of the most neglected.

7. Incorrect PLC Programming or Firmware Issues

A single incorrect logic step or untested update can disrupt the entire system.

Typical programming-related issues include:

-

Infinite loops

-

Incorrect scan times

-

Wrong I/O addressing

-

Outdated firmware

-

Unmanaged memory usage

Even a well-designed logic can fail when firmware isn’t updated as per vendor recommendations.

8. Harsh Environmental Conditions

Marine and industrial plants expose PLCs to severe conditions:

-

Salty atmosphere

-

High vibration

-

Oil mist

-

Chemical vapors

-

Continuous moisture

Without proper IP-rated enclosures or conformal coatings, modules wear out quickly.

9. Overloaded Communication Networks

Industrial networks like Profibus, Modbus, CANbus, and Ethernet/IP can fail due to:

-

Too many devices on a single network

-

Poor connectors

-

Damaged fiber cables

-

Improper grounding

-

Mixing high-noise and low-noise paths

This leads to communication faults, I/O delays, and recurring downtime.

10. Use of Incorrect or Low-Quality Replacement Parts

Installing non-genuine or incompatible spare parts is one of the biggest contributors to repeated PLC failure.

Examples:

-

Wrong power supply ratings

-

Third-party I/O with mismatched specifications

-

Poor-quality relays & connectors

-

Used modules without proper testing

-

Mixing different firmware revisions

Industrial plants must always use verified, compatible, and tested components.

Applications Where PLC Reliability Is Critical

PLCs are essential across industries such as:

Marine & Ship Automation

Ballast systems, engine room control, fire detection, navigation, hydraulic operations.

Manufacturing Plants

Packaging lines, CNC machines, conveyors, process automation.

Oil & Gas

Pipeline monitoring, drilling rigs, offshore safety systems.

Power Plants

Turbine control, switchgear automation, SCADA integration.

Food & Beverage

Batch control, temperature regulation, conveyor systems.

Pharmaceuticals & Chemicals

Mixing lines, cleanroom automation, safety interlocks.

Repeated PLC failures in any of these environments can result in dangerous downtime and heavy financial loss.

Why Choose the Right Components to Prevent PLC Failures?

Using the correct components, sourcing from reliable suppliers, and following proven maintenance practices ensures:

Long-term reliability & system stability

Quality modules reduce the chance of recurring failures.

Reduced maintenance & downtime costs

Less repair time = more productivity.

Better safety & compliance

Avoiding failures improves worker safety and meets industry standards.

Improved performance with accurate inputs/outputs

Reliable readings and outputs ensure smooth operation.

Peace of mind for maintenance teams

Knowing the system won’t fail overnight is priceless.

Why Choose Aeliya Marine Tech for PLC Components?

At Aeliya Marine Tech, we specialize in industrial and marine automation parts, offering:

-

100% tested, verified PLC components

-

Hard-to-find PLC modules, power supplies & I/Os

-

Fast delivery worldwide

-

Expert guidance for compatibility

-

Large inventory of OEM brands (ABB, Siemens, Honeywell, Omron, Allen-Bradley, Mitsubishi, Danfoss & more)

-

Reliable parts = reliable plants.