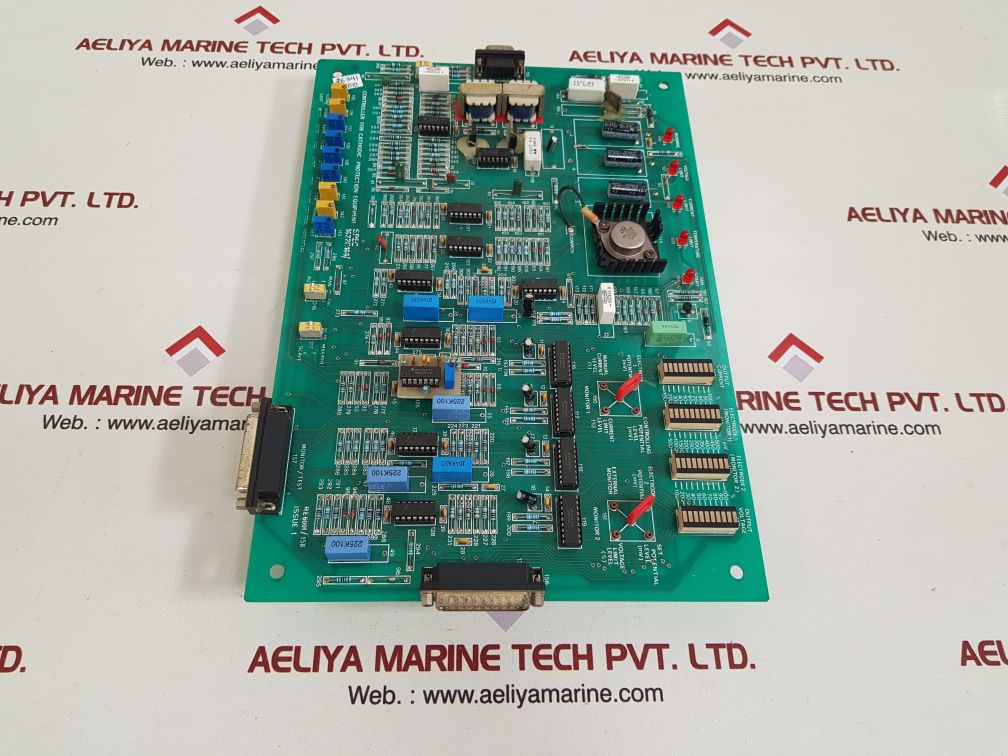

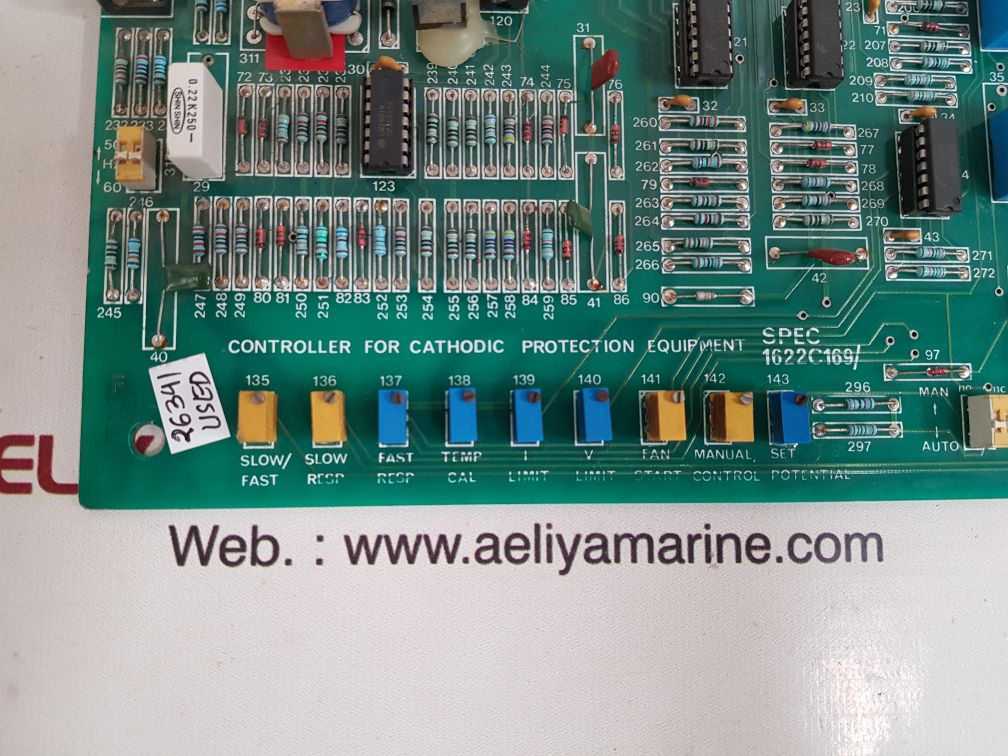

SPEC 1622C169 CONTROLLER FOR CATHODIC PROTECTION EQUIPMENT

CONTROLLER FOR CATHODIC PROTECTION EQUIPMENT

SPEC 1622C169

RE6001/158

WEIGHT : 550 GM

CONDITION : USED 2 PCS

REF NO : 26341

What is Cathodic Protection?

The SPEC 1622C169 controller, let’s clarify what cathodic protection is. A metal structure submerged in a corrosive environment, like an underwater pipeline or a ship’s hull. This metal is susceptible to rust or corrosion. Cathodic protection is a technique used to prevent this corrosion by making the metal structure the cathode of an electrochemical cell.

The Role of the Controller

The SPEC 1622C169 controller is the brain behind this operation. It’s a specialized piece of equipment designed to regulate and monitor the cathodic protection system. Its primary function is to ensure that the metal structure is adequately protected from corrosion without wasting energy or resources.

How Does it Work?

- Monitoring Corrosion Rates: The controller constantly measures the electrical potential of the metal structure. This data helps determine the level of protection it’s receiving.

- Adjusting Current Output: Based on the monitoring data, the controller adjusts the output of the power source to maintain the optimal level of protection.

- Data Logging: It records crucial information about the system’s performance, such as current output, voltage, and environmental conditions. This data is invaluable for troubleshooting and optimizing the system.

- Alarm Functions: The controller is equipped with alarms to alert operators of any anomalies or potential issues, such as a drop in protection level or equipment malfunction.

Key Features and Benefits

- Precision Control: Ensures optimal protection while minimizing energy consumption.

- Reliable Performance: Built to withstand harsh environments and operate continuously.

- Data-Driven Optimization: Provides insights for improving system efficiency and effectiveness.

- Early Warning System: Helps prevent costly equipment failures through timely alerts.

Applications of the SPEC 1622C169 Controller

The SPEC 1622C169 controller finds applications in various industries, including:

- Oil and Gas: Protecting pipelines, storage tanks, and offshore platforms from corrosion.

- Marine: Safeguarding ship hulls, underwater structures, and offshore installations.

- Water Treatment: Preventing corrosion in water storage tanks and distribution systems.

- Infrastructure: Protecting bridges, culverts, and other metal structures from environmental degradation.