Variable Frequency Drives (VFDs), servo drives, and DC drives are the workhorse of the motor control system in the industrial and marine automation industry. These control the speed, torque, and performance variations of conveyors, pumps, compressors, cranes, and propulsion systems. But when it comes to powering up drives without inspection, especially surplus or spare industrial drives, it may result in critical failures or even damage to the equipment.

Whether you are replacing a drive in a manufacturing plant or using a surplus drive for a marine application, it is always important to follow a pre-power checklist. This short guide will provide the most essential steps at the technician level to achieve a successful startup.

Why a Pre-Power Check Is Critical

A pre, power check is basically a pre, preventive inspection and verification procedure that needs to be carried out before a second-hand, spare, or newly installed industrial drive is powered on and used. The drive is inspected to be electrically safe, mechanically sound, properly configured, and compatible with the attached motor and power supply.

In the factory automation industry, taking any shortcuts during the inspection procedure before powering the drive may result in potential breakdowns of the hardware immediately, damage to the motor, halted production, or even pose any safety hazards.

Here’s Why It’s So Important:

- Protects Against Instant Electrical Damage: There may be some hidden issues in the second-hand drive, such as shorted IGBTs, faulty capacitors, or damaged PCBs. If you are applying full voltage without checking, you may end up burning the drive beyond recognition.

- Protects the Connected Equipment: Motors, gearboxes, pumps, and other connected equipment may be damaged because of improper voltage rating, improper parameter setting, or improper wiring.

- Reduces Unplanned Downtime: An unplanned drive failure during startup may mean that production lines, ship operations, or plant operations may have to be shut down, which may be costly.

- Ensures Proper Configuration: Second-hand drives often retain the settings of the former owner. If these settings are not corrected, the motors may be running too hot, or the motors may be suddenly turned off.

- Emphasizes Work Safety: The field of industrial drives is a high, voltage field and these drives are capable of storing residual energy. One of the things that proper inspections can do is reduce the hazards of electric shock, arc faults, or sudden motor start.

- Protects the Life of Your Equipment: Gradual startup and checks prevent the sudden shock to the internal parts that could have adverse effects. In this way, the proper working condition of equipment is protected

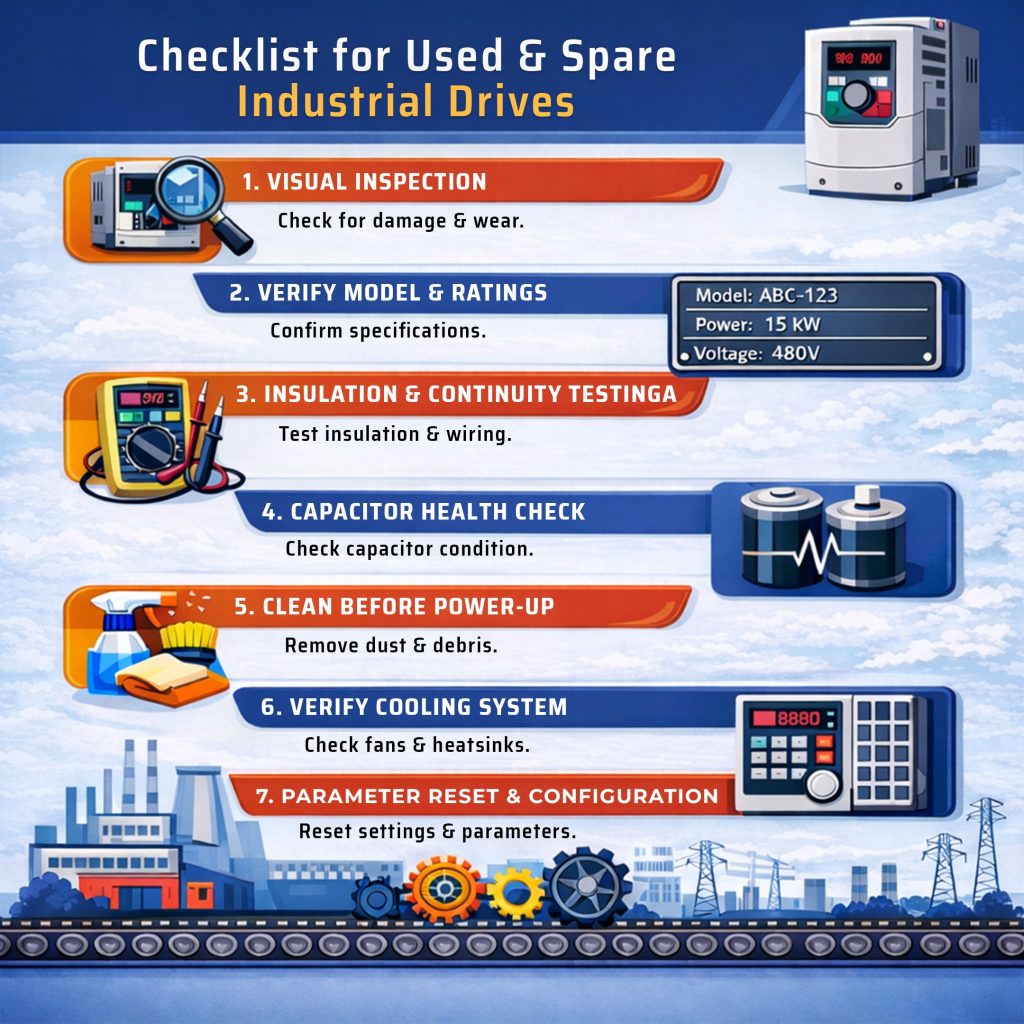

Checklist for Used & Spare Industrial Drives:

Visual Inspection:

Visual inspection is the step of looking for evidence of misuse and internal damage to the drive. This includes checking the basic characteristics to burn signs, burnt traces or components, rust on loose terminals, missing screws, dust accumulation, and heat damage. Moreover, if possible, checking the capacitors and PCBs internally for bulging or discoloration should also be considered. Visual inspection is a good way to begin a technical inspection, provided one has knowledge of equipment for new applications.

Verify Model & Ratings:

The verification of the correctness of the model and ratings is part of the process of ensuring that the drive is appropriate for the task it was designed for. This includes, but is not limited to, the verification of the voltage rating, current rating, frequency compatibility, motor rating (kW/HP), and phase configuration. It will be the most effective way of preventing the risk of overloading, overheating, or electrical damage at the same time to ensure that the ratings of the drive are compatible with the motor and the power supply.

Insulation & Continuity Testing:

Insulation and continuity testing is a technique of testing the electrical condition of the drive. Using a multimeter or insulation tester, it is ensured that there are no phase-to-phase shorts, no ground faults, and that the grounding is correct. This test has the capability to detect any hidden electrical faults that are not visible to the naked eye, but can be extremely harmful to the drive if it is energized.

Capacitor Health Check:

Capacitor health check is a technique of checking the condition of the DC bus capacitors, most especially in drives that have been lying idle for a long period of time. Capacitors can degrade, develop leaks, or reduce their efficiency with time. Checking for bulging, leaks, or erratic performance is a technique of ensuring that the drive has the capability to withstand high voltage safely. At times, it may be necessary to apply voltage gradually to the capacitors to restore them to normal.

Clean Before Power-Up:

Clean before power-up refers to the removal of dust, debris, and other contaminants from the drive using dry compressed air or a soft brush. Dust and conductive materials can cause overheating and/or shorting. The airflow and components can be inspected to ensure reliability and spurious error avoidance.

Verify Cooling System:

Verification of the cooling system refers to the verification of heat dissipation components such as fans, heat sinks, and airflow paths. Drives can produce a substantial amount of heat during normal operation, and an improper cooling system can cause overheating and failure of the drive.

Parameter Reset & Configuration:

Parameter reset and configuration ensure that the drive is properly set up for the new application. Used drives often retain previous settings, which may not match the current motor or system requirements. Resetting to factory defaults and entering correct motor parameters, voltage limits, frequency ranges, and control modes prevent operational instability and protect equipment.

Used and surplus industrial drives are a low-cost and very viable solution to the maintenance replacement, emergency backup, and system upgrade requirements. However, the reliability of these drives is not simply a function of the brand or type. it is also a function of the level of diligence exercised in their inspection and testing prior to the power being turned on.

The pre, power checklist is more than simply a technicality; it is a preventative measure. The visual inspection, electrical test, capacitor check, parameter setting what is not to be overlooked in each case ensuring safe start-up and reliable performance. Any process step that is not confirmed can result in damage to equipment, loss of production, or even a serious safety risk.

After a disciplined routine of inspections, the technicians and maintenance team can avoid a large number of startup failures; they can also safeguard the motors and machines that are connected and eventually, they can increase the life of the entire automation system. Where some loss of production time means losing money, preventive maintenance is not only a safer choice but also an inexpensive one.

In layman’s terms, a pre, power check is like turning suspicion into trust. It ensures that any industrial drive, whether it is new or used, is powered without any risk, operates at the best level, and from the very first startup, it can be trusted for a continuous running of operations.