Factors to Consider When Buying Refurbished PLC Modules

Refurbished PLC modules have emerged as a very smart option in the industrial world to meet the rising requirements for automation at affordable costs, without spending excessively on brand-new components. Be it a manufacturing plant, a marine vessel, or an industrial automation line, refurbished PLC modules are a very good value-for-money proposition if selected intelligently.

However, purchasing refurbished parts requires knowledge. Not every refurbished PLC is the same, and their quality will vary depending on the supplier, testing standards, condition of parts, and compatibility. Knowing what to look for can save you from costly downtime and keep your automation system running smoothly.

The following guide describes what refurbished PLC modules are, their key features, areas of application, and what one should consider while buying them — particularly for industrial users who rely on dependable automation parts.

What Are Refurbished PLC Modules?

Refurbished PLC modules are previously used, repaired, or restored to full working condition. Refurbishment is done through cleaning, inspection, replacement of worn parts, recalibration, and full functional testing to ensure operational reliability.

When new PLC components are either very expensive or no longer manufactured, refurbished modules are an affordable solution that is immediately available, particularly in legacy systems.

A quality refurbished PLC module should perform close to a new unit, as long as it comes from a reputable supplier and passes industry-standard testing.

Key Features of Quality Refurbished PLC Modules

1. Detailed Inspection and Repair

Quality refurbishing of PLCs involves thorough inspection for faults, damaged components, or corrosion; replacement is done with genuine equivalents for any worn-out parts.

2. Functional Testing

Good suppliers test each module against real-world operating conditions. This includes I/O checks, communication tests, power cycle tests, and temperature checks.

3. Firmware and Software Validation

It is recommended that the module be updated or checked for compatibility with the existing firmware versions to ensure smooth integration with your automation network.

4. Cleaned and Reconditioned Exterior

A good refurbishing would include physical restoration: cleaned terminals, polished body, no rust, proper labeling, and safe packing.

5. Lower cost than purchasing new modules

Refurbished modules are usually 40-70% cheaper than new ones, thus being very budget-friendly and especially valuable in the case of very expensive PLC systems.

6. Availability for Discontinued Models

Most of the legacy PLC systems from Siemens, Allen-Bradley, Mitsubishi, Omron, Delta, and ABB are no longer in production. Refurbished modules keep older machines running without expensive upgrades.

7. Warranty and Technical Support

Quality suppliers provide warranty assurance and after-purchase support to assist you in installing and troubleshooting the unit.

Applications of Refurbished PLC Modules

The refurbished PLC modules find their applications across industries where automation reliability and cost-efficiency are Lucas.

- Marine and Shipboard Automation

Used for navigation systems, engine control rooms, ballast systems, and safety monitoring.

- Manufacturing and processing plants

Ideal for conveyor systems, packaging machinery, robotic automation, and assembly lines.

- Power Plants and Energy Systems

Used in generator synchronizing, turbine controls, switchgear automation, and power distribution.

- Oil & Gas and Petrochemical Operations

Ideal applications include compressor plants, pumping systems, tank monitoring, and hazardous-area operations.

- Food & Beverage and Pharma Industries

Support precise temperature, pressure, and process control at low maintenance costs.

- HVAC and Building Management Systems

Used for monitoring chillers, AHUs, lighting, sensors, and emergency systems.

- Water Treatment and Utility Plants

Ensure that pumps, filtration units, and SCADA-based control systems operate reliably.

Why Choosing the Right Refurbished PLC Matters

A wrong or poor-quality PLC module results in severe problems:

- Unexpected machine shutdowns

- Production loss

- Troubleshooting delays

- Compatibility issues

- Risk of Electrical Faults

- Higher long-term costs

This is why the selection of refurbished components with proper evaluation is crucial.

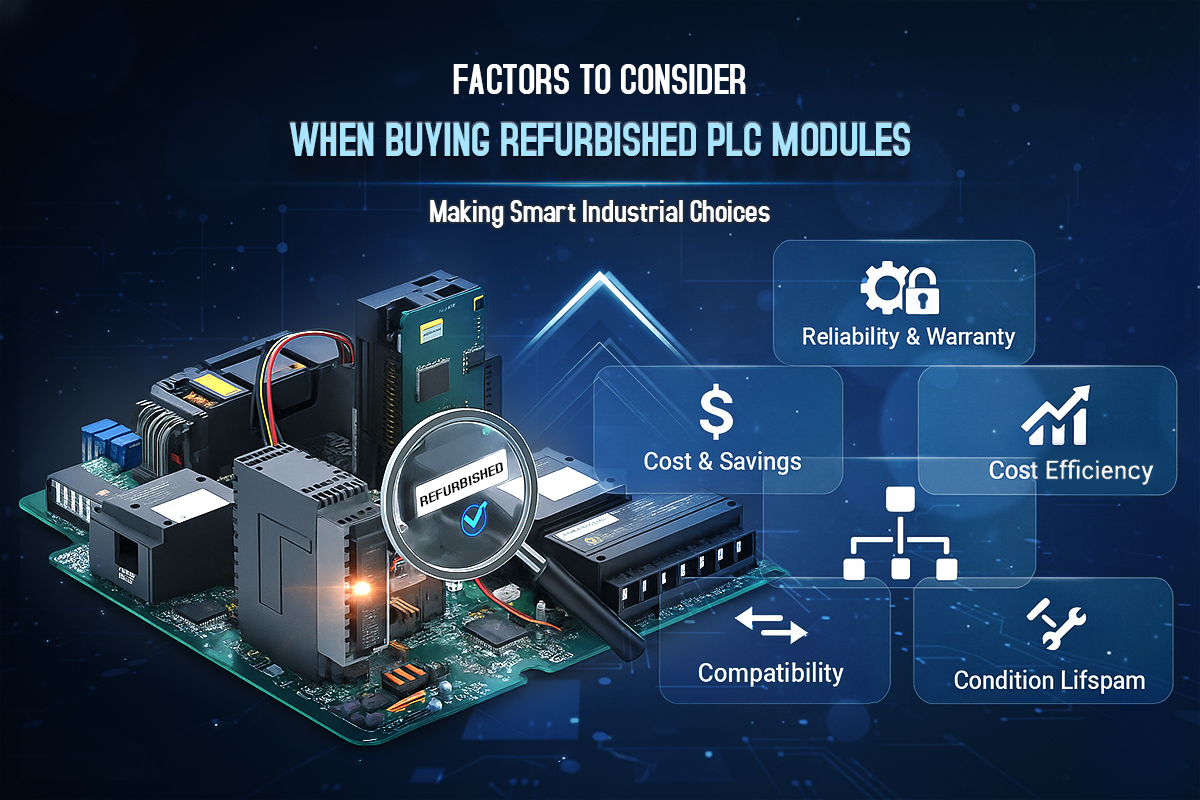

Factors to Consider Before Buying Refurbished PLC Modules

Below are the most important things to check before purchasing a refurbished PLC module.

1. Check the Supplier’s Reputation

Buy from trusted suppliers specializing in industrial automation components. A trusted supplier should have:

- A strong online presence

- Verified customer reviews

- Clear return and warranty policies

- Experience with numerous PLC manufacturers

2. Check the Test Process

Before purchasing, ensure that this unit has passed:

- I/O testing

- Load and stress testing

- Memory and CPU checks

- Power cycle tests

- Tests of environmental influence and temperature

A well-tested module operates with consistency and dependability.

3. Understand the Condition Grade

Refurbished modules can fall under:

- Like-new

- Excellent

- Good

- Functional but cosmetic wear

Select the appropriate grade to suit your budget and technical expectations.

4. Ensure Compatibility

Verify that the PLC module matches :

- The precise model number

- Firmware version

- I/O configuration

- Power requirements

- Communication protocols

- Rack or chassis type

5. Warranty Support

A genuine refurbished product will include:

- Minimum 3–6 month warranty

- Replacement support

- Return/refund options

Avoid those suppliers that don’t give any warranty — it means uncertain quality.

6. Price vs. Quality

Cheapest may not always be the best. Instead, look for:

- Fair Pricing

- Verified testing

- Good condition

- Reliable supplier

A well-overhauled PLC provides long-term savings through the prevention of breakdown issues.

7. Packaging and Shipping Standards

PLC modules should be shipped in:

- Anti-static packing

- Protective cushioning

- Watertight sealing

- Safety boxes

This prevents transit damage, especially for sensitive electronic modules.

8. Availability of Technical Documentation

Ask for:

- Product manuals

- Specification sheets

- Wiring diagrams

- Firmware information

This ensures smooth installation and integration.

Why choose refurbished PLC modules from Aeliya Marine Tech?

Aeliya Marine Tech is a trusted source for refurbished, tested, and ready-to-use industrial automation modules. Here’s why customers prefer us:

✔ Wide Range of PLC Brands

Siemens, Allen-Bradley, Mitsubishi, Omron, Schneider, ABB, Delta, GE Fanuc, and many more.

✔ 100% Tested Components

Every module is checked carefully prior to dispatch.

✔ Support for Legacy and Obsolete Models

We maintain the functionality of older automation systems for industries.

✈ Fast Worldwide Shipping

Well-packed units, delivered anywhere with express courier options.